Innovative Applications of Titanium Alloys in Precision Casting

Introduction to Titanium Alloys in Precision Casting

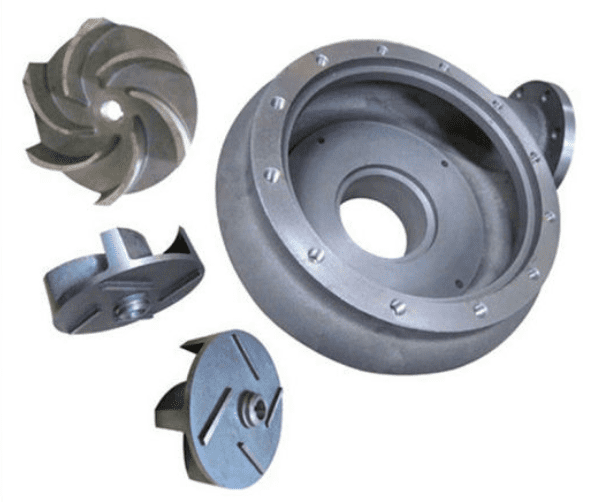

Precision casting, a vital process in modern manufacturing, is renowned for its ability to produce intricate and detailed components with remarkable accuracy. This advanced casting method is essential across diverse industries, where the demand for precision and quality is paramount.

In the realm of precision casting, titanium alloys stand out due to their unique combination of attributes. These alloys are celebrated for their exceptional strength, lightweight nature, and superior corrosion resistance. Such characteristics make them an ideal choice for precision casting, where these qualities can significantly enhance the performance and longevity of components.

This article aims to delve into the innovative applications of titanium alloys within the sphere of precision casting. We will explore how these alloys are not only transforming the manufacturing landscape but also contributing to significant advancements in various sectors, including aerospace, automotive, and medical devices. By examining their use in precision casting, we seek to highlight the role of titanium alloys in pushing the boundaries of modern manufacturing capabilities.

Composition and Properties of Titanium Alloys

Chemical Composition of Titanium Alloys Titanium alloys used in precision casting are known for their unique composition. Here’s a typical breakdown of their key elements:

| Element | Percentage (%) |

| Titanium (Ti) | 90 – 94 |

| Aluminum (Al) | 3 – 6 |

| Vanadium (V) | 2 – 4 |

| Nickel (Ni) | 0 – 0.5 |

This composition results in a combination of beneficial properties that make titanium alloys ideal for precision casting.

Key Properties of Titanium Alloys

High Strength-to-Weight Ratio: Titanium alloys are incredibly strong yet surprisingly light, making them suitable for applications where both strength and reduced weight are essential.

Superior Corrosion Resistance: Titanium’s resistance to corrosion and environmental degradation makes these alloys durable in harsh conditions.

Exceptional Thermal Stability: Maintaining strength and integrity at high temperatures, titanium alloys are perfect for components exposed to extreme heat.

Advantages in Precision Casting

Enhanced Durability and Resilience: The robust nature of titanium alloys means components are more resistant to wear, tear, and corrosion.

Suitability for Complex Designs: Due to their malleability, titanium alloys are ideal for casting intricate and detailed parts.

Industry Applications: From aerospace to medical implants, titanium alloys enable precision casting of components that demand high performance and reliability.

In conclusion, titanium alloys’ unique composition and properties make them a prime choice for precision casting, enabling the creation of high-quality, durable, and efficient components across various industries.

Industry Applications of Titanium Alloys in Precision Casting

Aerospace Industry Applications In the aerospace sector, titanium alloys are instrumental due to their remarkable strength coupled with lightweight properties. These alloys are commonly utilized for manufacturing critical components such as engine parts, airframes, and landing gear. Their ability to withstand extreme temperatures and pressures without adding significant weight makes titanium alloys indispensable in this field. This combination of durability and lightness contributes to fuel efficiency and overall performance enhancement of aircraft.

Medical Device Manufacturing Titanium alloys hold a pivotal role in medical precision casting, especially for implants and surgical instruments. Their exceptional biocompatibility prevents adverse reactions in the human body, making them a preferred choice for long-term medical applications. Furthermore, their strength ensures the durability of medical devices, an essential factor in surgical tools and implants like hip and knee replacements, where reliability and longevity are crucial.

Automotive and Sports Equipment Usage In the automotive industry, titanium alloys are used to create high-performance parts. Their strength improves safety and durability, while their lightweight nature contributes to better fuel efficiency and speed. Similarly, in sports equipment manufacturing, titanium alloys are favored for their durability and lightweight characteristics. They are used in making robust yet lightweight gear such as bicycle frames, golf clubs, and racing components, where performance and ease of use are key.

In summary, titanium alloys are transformative in precision casting across various industries. Their unique properties enable the creation of high-quality, durable, and efficient components in aerospace, medical, automotive, and sports equipment, underscoring their versatility and value in modern manufacturing.

Technological Advancements and Challenges

Innovations in Casting Techniques Recent advancements in precision casting have significantly enhanced the utilization of titanium alloys. Innovations such as investment casting and 3D printing have allowed for more intricate designs and improved material properties. These techniques have facilitated the casting of titanium alloys with greater precision and less waste, optimizing the production process. The use of computer-aided design (CAD) and simulation software has also improved the accuracy and efficiency of casting, enabling the creation of complex shapes that were previously challenging to manufacture.

Challenges in Manufacturing Despite these advancements, casting titanium alloys presents unique challenges. The high melting point of titanium requires specialized furnaces and handling equipment, leading to increased production costs. Additionally, titanium’s reactivity at high temperatures necessitates controlled environments to prevent contamination. This complexity requires a higher level of expertise and precision in the casting process.

Solutions and Future Outlook To address these challenges, ongoing research focuses on developing more efficient casting methods and materials that can withstand high temperatures. Investment in advanced equipment and training for specialized personnel is essential. The future outlook for titanium alloys in precision casting is promising, with continuous innovation expected to overcome current limitations. As technology evolves, we anticipate a broader application of titanium alloys, making them more accessible and cost-effective for various industries.

PrecisionVast’s Role and Future Prospects

PrecisionVast, with its deep-rooted expertise in precision casting, has been at the forefront of incorporating titanium alloys into its manufacturing processes. Recognizing the unique properties of titanium alloys, the company effectively utilizes them to produce components that are not only structurally sound but also lightweight and durable. By embracing innovative approaches such as advanced simulation techniques and cutting-edge casting methods, PrecisionVast has overcome the challenges associated with titanium alloy casting, such as high melting points and material reactivity.

The company’s commitment to innovation doesn’t stop there. PrecisionVast is dedicated to ongoing research and development, focusing on harnessing the full potential of titanium alloys. This commitment extends to adopting sustainable practices in precision casting, ensuring that environmental impact is minimized. PrecisionVast’s efforts in advancing titanium alloy applications play a crucial role in shaping the future of manufacturing, promising more efficient, sustainable, and versatile production capabilities across various industries.