Aluminum casting processes play a critical role in manufacturing. Whether you’re looking to create intricate designs or mass-produce parts, understanding these processes is crucial to achieving efficiency and quality.

In this guide, we’ll explore the different types of aluminum casting processes, their applications, and how to choose the right one for your needs.

When you think about aluminum casting, you might wonder what process best suits your project. Let’s dive into the core of aluminum casting processes and help you identify the best fit for your needs.

1. What Are Aluminum Casting Processes?

Aluminum casting processes are key to creating high-precision parts for various industries. Understanding these processes is the first step in achieving high-quality outcomes.

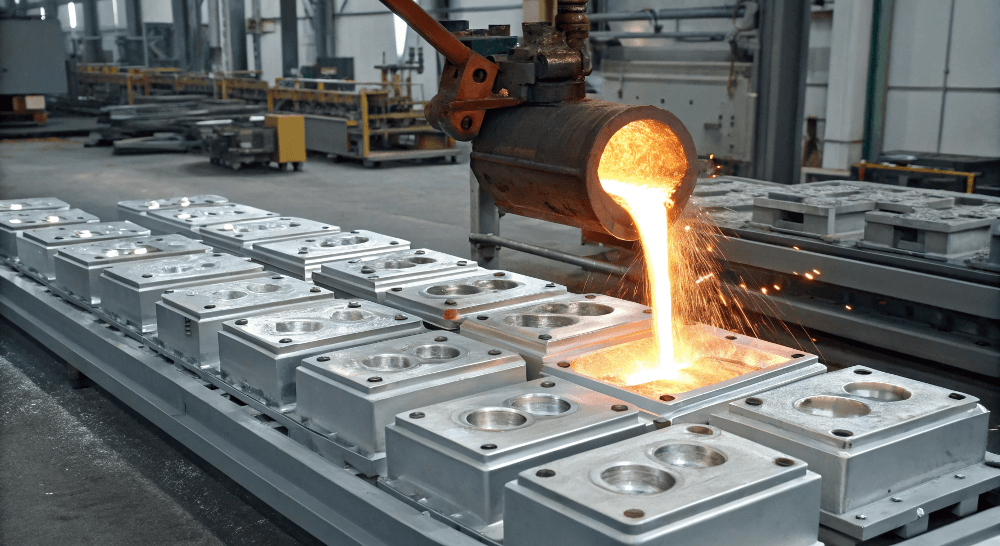

Aluminum casting is the method of pouring molten aluminum into molds to create parts. This process ensures the parts take the desired shape and size, depending on the mold used.

Casting aluminum has been an essential technique in industries such as automotive, aerospace, and consumer goods. Now, let’s explore the specific processes and why they are important.

Types of Aluminum Casting Processes

● Sand Casting

● Die Casting

● Investment Casting

● Permanent Mold Casting

Benefits of Aluminum Casting

● Cost Efficiency

● Lightweight and Durable Parts

● Versatility

| Casting Process | Advantages | Applications |

|---|---|---|

| Sand Casting | Low cost, versatile | Automotive parts, sculptures |

| Die Casting | High precision, fast production | Electronics, automotive parts |

| Investment Casting | High accuracy, complex designs | Aerospace, medical devices |

| Permanent Mold Casting | Reusable molds, high surface finish | High-volume production of parts |

Aluminum casting provides a range of benefits, especially when it comes to creating complex shapes. Depending on your project’s needs, one of these processes may be ideal.

2. Why Are Aluminum Casting Processes Important?

Aluminum casting processes are vital in industries like automotive and aerospace. They offer a versatile, cost-effective way to create components that are lightweight and durable.

These processes are crucial because they allow manufacturers to create parts that would otherwise be difficult to produce using other methods.

The flexibility of aluminum casting allows for a variety of shapes, improving efficiency while keeping production costs low. Whether you need a complex design or a simple part, casting processes can accommodate both.

Applications of Aluminum Casting

● Automotive Parts

● Aerospace Components

● Consumer Electronics

Benefits of Aluminum Casting in Industry

● Efficiency in Mass Production

● Enhanced Product Strength

● Wide Range of Applications

| Industry | Applications | Key Benefits |

|---|---|---|

| Automotive | Engine blocks, wheels | Lightweight, durable |

| Aerospace | Aircraft components | High strength-to-weight ratio |

| Consumer Electronics | Enclosures, housings | Corrosion resistance, precision |

In industries where precision is key, aluminum casting processes are essential for meeting manufacturing demands. Let’s take a deeper look into how each casting process works.

3. How Does the Aluminum Casting Process Work?

Aluminum casting involves several stages, from preparation to final inspection. Let’s break down the steps involved in aluminum casting.

The process begins by heating aluminum until it melts, followed by pouring it into molds. Once the aluminum cools, it solidifies into the shape of the mold.

Each aluminum casting process shares common steps, but the equipment and methods used vary, which influences the final product.

Key Steps in Aluminum Casting

- Melting the Aluminum

- Pouring the Molten Aluminum

- Solidifying the Mold

- Finishing the Cast Part

Tools and Equipment Used

● Furnaces

● Molds

● Cooling Chambers

| Step | Process Description | Equipment Needed |

|---|---|---|

| Melting | Heat aluminum until it melts | Furnace, Crucible |

| Pouring | Pour molten aluminum into mold | Molds, Ladles |

| Solidifying | Allow aluminum to cool and solidify | Cooling Chambers |

| Finishing | Clean and finish cast parts | Finishing Tools, Sandblasting |

Aluminum casting requires precision and control, especially when it comes to managing temperatures and mold designs. Let’s look at how different methods of aluminum casting can meet varying demands.

4. What Are the Types of Aluminum Casting Processes?

There are various types of aluminum casting processes, each suited for different manufacturing needs. Let’s examine the key types and their benefits.

Aluminum casting comes in several types, including sand casting, die casting, and investment casting. Each offers unique advantages depending on the application.

Each casting method has its strengths and is chosen based on factors like complexity, volume, and cost.

Types of Aluminum Casting

● Sand Casting

● Die Casting

● Investment Casting

● Permanent Mold Casting

Pros and Cons of Each Type

| Process Type | Pros | Cons |

|---|---|---|

| Sand Casting | Low cost, versatile | Surface finish issues |

| Die Casting | High precision | Expensive for low volumes |

| Investment Casting | High accuracy, detailed | High cost for low volumes |

| Permanent Mold | Good surface finish | Limited to lower complexity shapes |

Each method brings something unique to the table, depending on the needs of your project. Let’s discuss the specifics of sand casting next.

5. How Does Sand Casting Work in Aluminum Casting?

Sand casting is one of the most common aluminum casting processes. It’s an affordable and versatile option, especially for custom designs.

In sand casting, molds are made from a mixture of sand and binder. The molten aluminum is then poured into these molds to create the desired shape.

This method is popular due to its ability to handle complex shapes, though it may come with some trade-offs in surface finish.

Advantages of Sand Casting

● Low Cost

● Ideal for Custom Parts

● Can Handle Large Components

Disadvantages of Sand Casting

● Surface Finish May Need Additional Work

● Slower Than Other Methods

| Characteristic | Sand Casting |

|---|---|

| Cost | Low |

| Speed | Moderate |

| Customization | High |

Next, let’s explore die casting, another widely used method in aluminum casting.

6. What Is Die Casting and How Does It Work?

Die casting is a precision casting method where molten aluminum is injected into a mold under high pressure.

This method allows for tight tolerances and complex shapes but requires specialized equipment. It’s ideal for high-volume production.

Die casting is most beneficial when you need uniform parts produced quickly, but the initial investment can be higher than other methods.

Benefits of Die Casting

● High Precision

● Ideal for High-Volume Production

● Durable Parts

Challenges of Die Casting

● High Setup Costs

● Limited Material Options

| Feature | Die Casting |

|---|---|

| Precision | High |

| Setup Cost | High |

| Suitable for Low Volumes | No |

Let’s move on to investment casting, a method often used for very high precision parts.

7. How Does Investment Casting Work in Aluminum Casting?

Investment casting involves creating a mold by coating a pattern in a ceramic shell. Once hardened, the pattern is removed, and molten aluminum is poured into the mold.

This process is often used when high accuracy and intricate shapes are required. It’s most commonly found in aerospace and medical applications.

Investment casting is more expensive but offers the highest precision, making it ideal for industries where quality cannot be compromised.

Benefits of Investment Casting

● High Precision

● Ideal for Complex Shapes

● Excellent Surface Finish

Disadvantages of Investment Casting

● High Cost

● Time-Consuming

| Characteristic | Investment Casting |

|---|---|

| Precision | Very High |

| Cost | High |

| Complexity | High |

Next, let’s discuss permanent mold casting, often used for large production runs of medium-sized parts.

8. What Is Permanent Mold Casting in Aluminum Casting?

Permanent mold casting uses reusable molds to produce aluminum parts. The molds are made from materials like steel and can be used repeatedly.

This method is known for its ability to produce high-quality parts with excellent surface finishes. However, it is limited by the complexity of the shapes it can produce.

Permanent mold casting is less costly than investment casting but requires more upfront investment in molds.

Benefits of Permanent Mold Casting

● High Surface Quality

● Reusable Molds

● Cost-Effective for Medium Volumes

Limitations of Permanent Mold Casting

● Complex Shapes Are Not Feasible

● Mold Costs Are High

| Factor | Permanent Mold Casting |

|---|---|

| Surface Quality | Excellent |

| Complexity | Low |

| Production Rate | Moderate |

Aluminum casting provides a range of methods, each suited for different types of products and production volumes. As we move forward, let’s take a look at common defects and how to avoid them.

9. What Are the Common Defects in Aluminum Castings?

Aluminum casting defects can significantly impact the quality of the final product. Understanding these defects is critical to improving production and minimizing waste.

Common defects in aluminum castings include porosity, shrinkage, misruns, and cold shuts. These defects can affect both the aesthetic and functional properties of the cast part.

By identifying and understanding these defects, manufacturers can take steps to prevent them, ensuring better quality in aluminum castings.

Types of Defects in Aluminum Castings

● Porosity

● Shrinkage

● Misruns

● Cold Shuts

Preventing and Fixing Defects

| Defect | Cause | Prevention Method |

|---|---|---|

| Porosity | Gas trapped during casting | Use degassing methods, control pouring speed |

| Shrinkage | Metal contraction during cooling | Use proper gating systems, adjust cooling rate |

| Misruns | Molten metal does not fully fill mold | Use higher pouring temperature, improve mold design |

| Cold Shuts | Molten metal cools before it joins | Ensure proper pouring temperature, optimize gating |

Addressing these common defects early on can save time and reduce the need for rework, leading to better overall results.

10. How Do You Select the Best Aluminum Casting Process?

Choosing the right aluminum casting process depends on factors such as cost, complexity, and production volume. It’s essential to evaluate these aspects to find the best match for your needs.

The ideal casting process balances efficiency, cost, and quality. Factors like mold material, part complexity, and production quantity are critical in making the right choice.

This decision can be complicated, but understanding the trade-offs between different casting methods makes it easier to select the best approach for your project.

Factors to Consider When Choosing a Process

● Part Complexity

● Production Volume

● Cost Considerations

● Surface Finish

How to Choose the Best Process

| Factor | Sand Casting | Die Casting | Investment Casting | Permanent Mold Casting |

|---|---|---|---|---|

| Part Complexity | Low | High | Very High | Moderate |

| Production Volume | Low/Medium | High | Low/Medium | Medium |

| Cost | Low | High | High | Moderate |

| Surface Finish | Rough | Excellent | Excellent | Good |

By considering these factors, you can make a more informed decision and choose the best casting method for your needs.

11. What Are the Benefits of Using Aluminum in Casting?

Aluminum is widely used in casting due to its unique properties. Let’s explore why aluminum is an ideal material for casting processes.

Aluminum is lightweight, durable, and corrosion-resistant. These properties make it highly versatile for use in various industries such as automotive, aerospace, and electronics.

Its ability to be easily cast into complex shapes, along with its excellent strength-to-weight ratio, makes aluminum a preferred material for many applications.

Benefits of Aluminum in Casting

● Lightweight

● High Durability

● Excellent Corrosion Resistance

Why Aluminum is Ideal for Casting

| Property | Benefit for Casting |

|---|---|

| Lightweight | Reduces overall part weight, ideal for transport and automotive industries |

| Durability | Provides long-lasting performance in harsh conditions |

| Corrosion Resistance | Ideal for parts exposed to moisture or chemicals |

The use of aluminum in casting brings a range of benefits, especially in applications where strength, weight, and durability are crucial.

12. How to Ensure Quality in Aluminum Casting?

Ensuring quality in aluminum casting is vital to producing reliable, high-performance parts. There are several ways to guarantee that your castings meet the highest standards.

Quality assurance methods include controlling the casting environment, inspecting the final product, and implementing proper mold design.

By following rigorous quality control procedures, manufacturers can avoid defects and deliver superior aluminum castings.

Quality Control Measures

● Inspection of Cast Parts

● Temperature Control

● Mold Design Optimization

Role of Inspections in Quality Control

| Inspection Method | Description | Benefit |

|---|---|---|

| Visual Inspection | Inspecting for surface defects | Ensures visual quality |

| Ultrasonic Testing | Detects internal defects | Ensures part integrity |

| X-Ray Inspection | Detects internal voids | Ensures strength and safety |

By focusing on quality throughout the casting process, you can achieve the high standards required for critical applications.

13. What Are the Environmental Considerations in Aluminum Casting?

As sustainability becomes more important, it’s essential to evaluate the environmental impact of aluminum casting processes.

Aluminum casting can be energy-intensive, but there are many opportunities for improving sustainability by using cleaner technologies and reducing waste.

By adopting eco-friendly practices, manufacturers can reduce the environmental footprint of their casting processes.

Environmental Impact of Aluminum Casting

● Energy Consumption

● Waste Generation

● Emissions

Sustainable Practices in Aluminum Casting

| Sustainable Practice | Benefit | Example |

|---|---|---|

| Recycling Aluminum | Reduces waste and energy use | Using scrap aluminum in casting |

| Energy-Efficient Furnaces | Reduces energy consumption | Electric furnaces instead of gas-fired |

| Waste Reduction | Reduces environmental impact | Efficient use of sand molds |

Sustainability should be considered at every stage of the aluminum casting process, from material sourcing to waste management.

14. How Does Technology Impact Aluminum Casting Processes?

Technology plays a major role in improving the efficiency and precision of aluminum casting processes. From automated systems to advanced mold designs, technology is helping to shape the future of casting.

Technological advancements allow for better control over temperature, speed, and mold designs. Automation has also improved production rates, making aluminum casting more efficient.

The integration of modern technology helps manufacturers optimize casting methods, reduce waste, and achieve better precision.

Role of Automation in Aluminum Casting

● Robotic Pouring Systems

● Automated Quality Control

● Advanced Mold Design

Innovations in Aluminum Casting Technology

| Technology | Application | Benefit |

|---|---|---|

| Robotic Systems | Automation of casting process | Faster production, fewer errors |

| 3D Printing | Custom mold creation | Complex shapes, reduced lead time |

| AI for Quality Control | Automated inspection | More precise and consistent quality |

Technology in aluminum casting continues to evolve, driving improvements in both production and sustainability.

15. What Are the Challenges in the Aluminum Casting Industry?

The aluminum casting industry faces a range of challenges, from rising material costs to the need for improved environmental practices.

Challenges include supply chain disruptions, rising material costs, and maintaining high-quality standards amid growing competition.

By addressing these challenges, the industry can improve processes, reduce costs, and increase competitiveness.

Key Challenges Faced by Manufacturers

● Material Shortages

● Rising Costs

● Environmental Regulations

Overcoming Challenges

| Challenge | Solution | Result |

|---|---|---|

| Material Shortages | Invest in recycling technologies | Reduced reliance on raw materials |

| Rising Costs | Optimize production efficiency | Lower overall manufacturing costs |

| Environmental Regulations | Adopt sustainable practices | Compliance with regulations, reduced environmental footprint |

The aluminum casting industry faces hurdles, but these challenges also present opportunities for innovation and growth.

Conclusion

Aluminum casting processes are an essential part of manufacturing across various industries. From sand casting to die casting and investment casting, each method offers distinct advantages depending on the application.

Choosing the right casting method depends on your needs in terms of volume, cost, and precision. By understanding each method, you can make an informed decision that ensures the quality and efficiency of your production process.

FAQ Section

- Q1: What is aluminum casting?

Aluminum casting is a method of shaping aluminum by pouring molten metal into molds to form parts for various applications. - Q2: How does die casting work?

Die casting involves injecting molten aluminum under pressure into metal molds to create high-precision parts. - Q3: What are the different types of aluminum casting?

The main types include sand casting, die casting, investment casting, and permanent mold casting, each suited for different applications. - Q4: What are the common defects in aluminum castings?

Common defects include porosity, shrinkage, and cold shuts, which can affect the quality and performance of cast parts. - Q5: How can aluminum casting be made more sustainable?

Aluminum casting can be made more sustainable by reducing waste, improving recycling, and using energy-efficient production techniques.