Aluminum die casting alloys are crucial in creating durable, high-quality products. If you’re involved in manufacturing or design, you’ve probably already realized how important it is to choose the right alloy. The ideal alloy will depend on the specific needs of your project, the environment the product will operate in, and the desired characteristics such as strength, weight, and corrosion resistance. This article will break down the various aluminum die casting alloys, why the selection process is important, and how to choose the best one for your needs. Ready to dive in? Let’s explore!

1. What Are Aluminum Die Casting Alloys?

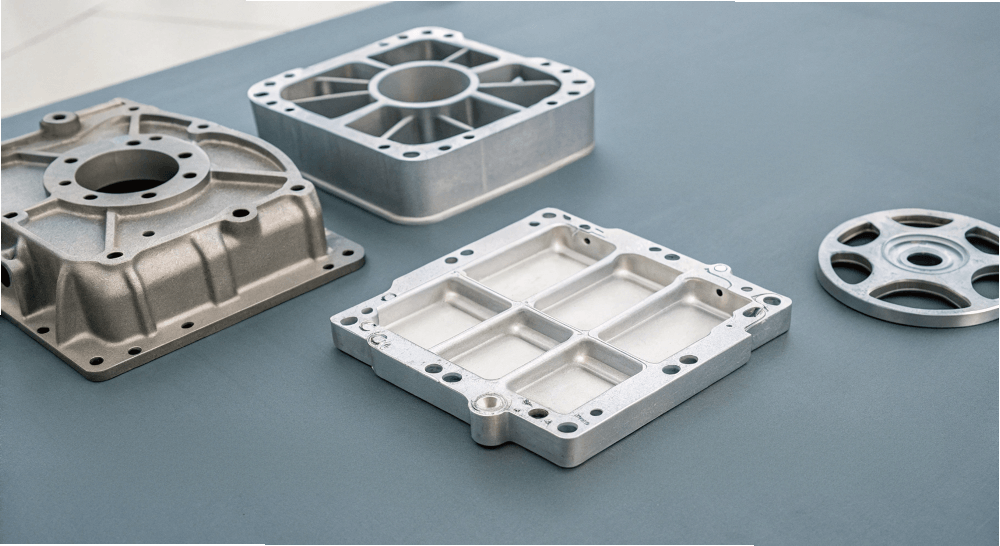

Aluminum die casting alloys are precisely formulated materials used in die casting, where molten metal is forced into molds to create precise, high-quality parts. Aluminum alloys used for die casting are typically composed of aluminum mixed with other metals such as copper, magnesium, silicon, and zinc. These alloys are chosen based on their properties, including their strength, castability, corrosion resistance, and workability.

But here’s the kicker: not all aluminum alloys are created equal. The right alloy can make a significant difference in your project’s success. The three most common types of aluminum alloys used in die casting include A380, A360, and A413. Each of these alloys has unique properties suited to different applications, ranging from automotive parts to aerospace components. For example, A380 is widely used in automotive and industrial applications because of its excellent castability and strength.

What’s the real story? Choosing the right alloy depends on a careful analysis of your project requirements. For instance, if you’re looking for high corrosion resistance, A360 might be the better choice, as it excels in marine and outdoor environments. Choosing the wrong alloy can lead to subpar performance, reduced durability, and higher costs.

| Alloy Type | Common Uses | Strength | Corrosion Resistance | Castability |

|---|---|---|---|---|

| A380 | Automotive, Industrial | High | Moderate | Excellent |

| A360 | Marine, Outdoor | Moderate | High | Good |

| A413 | Aerospace, Precision Parts | High | Moderate | Good |

2. What Are the Benefits of Using Aluminum Die Casting Alloys?

Aluminum die casting alloys offer a range of benefits that make them ideal for various industries. The most obvious advantage is their lightweight nature. Aluminum alloys are significantly lighter than many other metals, which is essential in industries such as automotive and aerospace, where reducing weight can improve fuel efficiency and performance.

But here’s the kicker: aluminum alloys also offer exceptional strength-to-weight ratios. This makes them suitable for producing large, robust components without adding unnecessary weight. In fact, some of the highest strength alloys available come from the aluminum family. Not only that, but aluminum alloys are resistant to corrosion, which makes them particularly useful in environments prone to moisture or chemicals.

Additionally, these alloys offer versatility in manufacturing. The die casting process allows for high-volume production of complex shapes and intricate designs, making it an excellent choice for producing parts at scale. Let’s take the automotive industry, for example. By using aluminum die casting alloys, manufacturers can produce lightweight car components, such as engine blocks and transmission housings, without compromising on durability. This results in better fuel efficiency and improved overall vehicle performance.

| Benefit | Description |

|---|---|

| Lightweight | Reduces weight in products, improving performance |

| High Strength-to-Weight Ratio | Ideal for robust components without adding unnecessary weight |

| Corrosion Resistance | Excellent in outdoor and chemical-exposure environments |

| Versatility | Suitable for producing complex, intricate parts at high volumes |

3. How Do Aluminum Alloys Impact the Die Casting Process?

The selection of aluminum alloys significantly impacts the die casting process. The alloy you choose will determine various aspects, including the casting method, mold design, and cycle time. For instance, A380 aluminum, known for its excellent castability, is often chosen when intricate designs and fast production are required. On the other hand, A360, with its superior corrosion resistance, might require different mold designs and cooling rates.

Ready for the good part? The die casting process itself is influenced by the alloy’s composition. Some alloys may require higher mold temperatures, faster injection speeds, or longer cooling times. This means that choosing an alloy with the right balance of flowability and strength is essential for optimizing the casting process.

Let’s break it down: alloys like A380 are ideal for creating complex shapes because they flow easily into molds and cool quickly, which increases production efficiency. However, more corrosion-resistant alloys like A360 may require slower cooling times but provide longer-lasting performance in harsh environments. By understanding how alloy selection affects the die casting process, manufacturers can make better choices and reduce production costs while maintaining high product quality.

| Alloy Type | Mold Design | Cooling Time | Injection Speed | Complexity of Design |

|---|---|---|---|---|

| A380 | Simple | Fast | High | High |

| A360 | Moderate | Slow | Moderate | Moderate |

| A413 | Complex | Moderate | Low | Very High |

4. What Are the Common Types of Aluminum Die Casting Alloys?

There are several types of aluminum die casting alloys available, each designed for different applications. The most commonly used are:

A380 – This alloy is one of the most popular choices in aluminum die casting due to its excellent combination of strength and castability. It is used widely in automotive and industrial parts such as engine blocks and housing.

A360 – Known for its exceptional corrosion resistance, A360 is ideal for marine and outdoor applications. This alloy is often used in parts that will be exposed to water or chemicals, such as pumps and valve bodies.

A413 – This alloy is used in aerospace and high-precision applications. It offers superior strength and can be cast into complex designs with fine details.

What’s the real story? Each alloy has its own unique combination of properties that make it suitable for certain environments and uses. Whether you need corrosion resistance, high strength, or precise details, there’s an aluminum die casting alloy that meets your specific requirements.

| Alloy Type | Best Use | Key Benefit |

|---|---|---|

| A380 | Automotive, Industrial | Excellent strength and castability |

| A360 | Marine, Outdoor | High corrosion resistance |

| A413 | Aerospace, Precision Parts | Superior strength and precision |

5. Why Is the Selection of Aluminum Die Casting Alloys Crucial?

Choosing the right aluminum die casting alloy is crucial for ensuring the performance and longevity of your final product. Selecting the wrong alloy can result in poor durability, corrosion, or unnecessary weight, all of which can negatively impact the end product’s performance.

But here’s the kicker: selecting the correct alloy doesn’t just affect performance—it can also influence your bottom line. By choosing an alloy that aligns with your project’s needs, you can minimize production costs, reduce waste, and improve the overall quality of the part. For instance, an alloy that cools quickly and is easy to cast might speed up production time and reduce costs, while an alloy with excellent corrosion resistance might lead to longer-lasting products, saving money in the long term.

When choosing an alloy, it’s important to carefully consider factors like the product’s operating environment, desired lifespan, and cost constraints. Do you need a high-strength part? Or is corrosion resistance more important? Once you have these answers, selecting the right alloy becomes much easier.

| Factor | Consideration |

|---|---|

| Performance Requirements | Strength, durability, corrosion resistance |

| Cost Constraints | Budget for material and manufacturing |

| Operating Environment | Exposure to chemicals, moisture, or extreme temperatures |

6. How Do Different Aluminum Alloys Compare in Terms of Strength?

Strength is one of the most critical factors when selecting an aluminum die casting alloy. Different alloys offer varying levels of tensile strength, which determines how much force an alloy can withstand before breaking or deforming.

Ready for the good part? Let’s look at how the most popular aluminum die casting alloys compare in terms of strength. A380 is known for its excellent strength-to-weight ratio, making it suitable for many general-purpose applications. However, if you need higher strength for heavy-duty parts, A413 might be a better option. This alloy is often used in aerospace applications, where strength is paramount.

For parts that will undergo less stress, A360 might be a great choice, as it offers moderate strength with exceptional corrosion resistance. By understanding the strength properties of each alloy, you can select the one that best suits the demands of your specific application.

| Alloy Type | Tensile Strength (MPa) | Best Use |

|---|---|---|

| A380 | 275-310 | General-purpose |

| A360 | 230-275 | Marine, Outdoor |

| A413 | 310-360 | Aerospace |

7. What Are the Best Aluminum Die Casting Alloys for Automotive Parts?

In the automotive industry, lightweight, durable, and cost-effective materials are key. Aluminum die casting alloys like A380 and A360 are widely used in automotive applications, as they provide the necessary strength and weight savings required for performance parts.

But here’s the kicker: aluminum die casting alloys for automotive parts need to withstand high temperatures, mechanical stresses, and exposure to harsh chemicals. A380 is a favorite in this industry because it provides high strength and excellent castability, which is essential for producing complex automotive components quickly and efficiently.

Additionally, alloys like A360 are often used for parts that are exposed to the elements, such as engine components and housings. These alloys offer great resistance to corrosion and can help automotive manufacturers produce parts that will last for many years. This means fewer replacements and repairs, leading to lower maintenance costs.

| Alloy Type | Strength | Corrosion Resistance | Automotive Use |

|---|---|---|---|

| A380 | High | Moderate | Engine blocks, transmission parts |

| A360 | Moderate | High | Housings, engine components |

8. How Do Aluminum Die Casting Alloys Perform in Aerospace Applications?

Aerospace applications demand high-strength, lightweight materials that can perform well under extreme conditions. Aluminum alloys such as A413 are often selected for aerospace components due to their excellent strength, low weight, and ability to withstand high pressures and temperatures.

What’s the real story? Aerospace parts need to meet stringent standards for safety and performance. Alloys like A413 are not only strong but also able to be cast into intricate shapes and designs. This makes them ideal for producing precision parts such as turbine blades, fuselage components, and other critical parts that are essential to flight safety.

By using aluminum die casting alloys, aerospace manufacturers can create components that are both strong and lightweight, reducing the overall weight of aircraft and improving fuel efficiency. This is where aluminum alloys truly shine—offering a balance of performance and cost-effectiveness.

| Alloy Type | Strength | Weight | Aerospace Use |

|---|---|---|---|

| A413 | High | Low | Precision parts, turbine blades |

| A360 | Moderate | Low | Aircraft housing, engine parts |

9. How Do Aluminum Alloys Compare to Other Metals in Die Casting?

When comparing aluminum alloys to other metals like zinc, magnesium, and copper, aluminum stands out due to its lightweight properties and excellent strength-to-weight ratio. While other metals like zinc and magnesium are also used in die casting, aluminum alloys often outperform them in applications requiring lightweight parts and corrosion resistance.

But here’s the kicker: aluminum is also highly versatile, with a wide range of alloys available that can be tailored to meet specific requirements. While zinc alloys excel in strength, they are heavier and more expensive than aluminum, making aluminum the more cost-effective choice for many high-volume applications.

Magnesium alloys, while lighter than aluminum, can be more difficult to cast, and their mechanical properties are not always as strong. Copper alloys, on the other hand, offer excellent corrosion resistance but are significantly heavier and more expensive than aluminum.

| Metal Type | Weight | Strength | Corrosion Resistance | Cost |

|---|---|---|---|---|

| Aluminum | Low | High | Excellent | Moderate |

| Zinc | Moderate | High | Moderate | High |

| Magnesium | Very Low | Moderate | Low | High |

| Copper | High | High | Excellent | Very High |

10. What Are the Common Defects in Aluminum Die Casting Alloys and How Can They Be Avoided?

Defects in aluminum die casting alloys can arise during the casting process, leading to defects such as porosity, shrinkage, and cracks. These defects can reduce the quality and durability of the final product, resulting in costly rework or scrap.

What’s the real story? Defects often occur when the casting process is not properly controlled, which is why selecting the right alloy is critical. For example, alloys with high shrinkage rates, such as some grades of A380, are more likely to form internal voids if the cooling process is not carefully managed.

To avoid these defects, manufacturers must ensure proper mold design, control cooling rates, and ensure the right alloy is used for the specific application. By carefully monitoring the casting process and selecting the best aluminum alloy, defects can be minimized, leading to higher-quality, more durable products.

| Defect Type | Cause | Prevention Measure |

|---|---|---|

| Porosity | Air trapped during cooling | Control mold pressure and cooling |

| Shrinkage | Alloy contraction during cooling | Use alloys with low shrinkage rates |

| Cracking | Stress during cooling | Control cooling rates and use the right alloy |

11. What Factors Should You Consider When Selecting an Aluminum Die Casting Alloy?

When selecting an aluminum die casting alloy, there are several key factors to consider, such as strength, corrosion resistance, weight, and cost. Each alloy has unique properties that make it suitable for different applications.

Ready for the good part? You should also think about the manufacturing process itself. Some alloys are easier to cast than others, which can impact production time and cost. For example, alloys like A380 are known for their excellent castability, meaning they can be used for complex shapes with minimal effort.

But here’s the kicker: the operating environment of the finished part is also important. If your part will be exposed to harsh chemicals, marine environments, or high temperatures, you’ll want to choose an alloy with high corrosion resistance and the strength to withstand these conditions.

| Factor | Consideration |

|---|---|

| Strength | Determine if high strength is needed |

| Corrosion Resistance | Choose alloys with high corrosion resistance |

| Cost | Evaluate the cost for the alloy and production |

| Manufacturing Process | Select alloys that are easier to cast for faster production |

12. How Do Surface Treatments Affect Aluminum Die Casting Alloys?

Surface treatments can significantly improve the performance and appearance of aluminum die casting alloys. Common treatments include anodizing, powder coating, and polishing, which enhance the alloy’s corrosion resistance, aesthetic appeal, and surface hardness.

What’s the real story? These treatments can make a huge difference in the final product, especially for parts that will be exposed to harsh environments or used in applications where appearance is important. Anodizing, for example, not only increases corrosion resistance but also provides a durable, attractive finish that is ideal for products used in consumer electronics or automotive parts.

Ready for the good part? These treatments can also enhance the durability of the alloy. Anodizing creates a hard oxide layer on the surface, while powder coating provides a protective layer that resists scratching, chipping, and fading.

| Surface Treatment | Benefits | Best Use |

|---|---|---|

| Anodizing | Increases corrosion resistance and surface hardness | Outdoor parts, automotive |

| Powder Coating | Provides a protective layer against scratches and fading | Consumer electronics, automotive parts |

| Polishing | Enhances appearance and smoothness | Decorative parts, precision components |

13. What Are the Environmental Benefits of Using Aluminum Die Casting Alloys?

Aluminum die casting alloys offer significant environmental benefits, primarily due to the recyclability of aluminum. Aluminum can be recycled multiple times without losing its properties, making it a sustainable material choice for die casting.

But here’s the kicker: recycling aluminum not only saves energy but also reduces carbon emissions. It takes only a fraction of the energy to recycle aluminum compared to producing new aluminum from bauxite ore, making it a more eco-friendly option for manufacturers.

What’s the real story? By using aluminum die casting alloys, manufacturers can reduce waste and minimize their environmental impact. In fact, recycled aluminum is often used in new casting projects, reducing the need for virgin aluminum and helping to conserve natural resources.

| Environmental Benefit | Description |

|---|---|

| Recycling | Reduces energy consumption and waste |

| Carbon Footprint | Lowers carbon emissions by using recycled aluminum |

| Resource Conservation | Conserves natural resources by reducing virgin material use |

14. How Do Aluminum Die Casting Alloys Contribute to Reducing Manufacturing Costs?

Aluminum die casting alloys help reduce manufacturing costs in several ways. First, aluminum is relatively inexpensive compared to other metals like copper or magnesium, making it a cost-effective choice for mass production.

Ready for the good part? Aluminum alloys are also lightweight, reducing shipping costs and overall production costs. By using lightweight materials, manufacturers can produce parts that are easier to handle and transport, which can lead to cost savings in logistics.

But here’s the kicker: aluminum alloys offer high casting efficiency. The fast cooling times of alloys like A380 allow for quicker production cycles, which means manufacturers can produce parts at scale without sacrificing quality.

| Cost Reduction Factor | Description |

|---|---|

| Material Cost | Aluminum is less expensive than other metals |

| Shipping Cost | Lightweight parts reduce transportation costs |

| Production Efficiency | Fast cooling alloys speed up production time |

15. What Are the Latest Trends in Aluminum Die Casting Alloys?

Aluminum die casting alloys are constantly evolving to meet the demands of modern industries. New alloys are being developed to offer enhanced properties, such as greater strength, lighter weight, and improved resistance to extreme temperatures.

What’s the real story? Advances in aluminum die casting technologies are allowing for the creation of more complex and intricate parts with better material properties. Emerging alloys are designed to meet the needs of industries such as aerospace, automotive, and electronics, where performance and durability are critical.

Ready for the good part? Some of the latest trends include alloys that are optimized for 3D printing, allowing manufacturers to create highly customized parts that meet precise specifications. These innovations are pushing the boundaries of what’s possible with aluminum die casting.

| Trend | Description |

|---|---|

| New Alloys | Alloys with improved strength, weight, and resistance |

| 3D Printing Alloys | Custom alloys optimized for additive manufacturing |

| Complex Parts | Creating more intricate parts for various industries |

FAQ Section

Q1: What is an aluminum die casting alloy?

An aluminum die casting alloy is a blend of aluminum and other metals used in the die casting process to create precise and durable parts. These alloys are selected based on their strength, workability, and resistance to environmental factors.

Q2: How does aluminum die casting work?

Aluminum die casting involves injecting molten aluminum alloy into a mold under high pressure. The mold is then cooled, solidifying the metal into the desired shape, creating complex and detailed components.

Q3: Why is alloy selection important in die casting?

The alloy selection impacts the strength, durability, cost, and performance of the finished part. Choosing the right alloy ensures the part meets specific requirements for the application, whether for strength, corrosion resistance, or weight.

Q4: What are the best aluminum die casting alloys for automotive parts?

A380 and A360 alloys are commonly used in the automotive industry due to their strength, light weight, and corrosion resistance. These alloys are ideal for producing components like engine blocks and transmission housings.

Q5: Can aluminum die casting alloys be recycled?

Yes, aluminum alloys are highly recyclable. Recycling aluminum reduces energy consumption and lowers carbon emissions, making it an environmentally friendly choice in manufacturing processes.