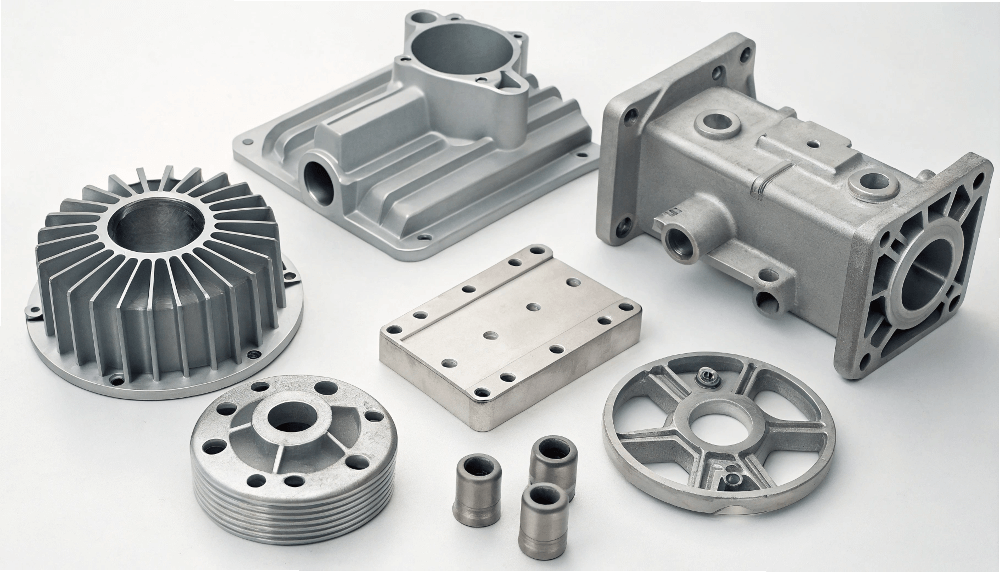

High pressure aluminum die casting is a popular and efficient method for manufacturing precision parts and components used in various industries. It involves injecting molten aluminum into a steel mold under high pressure to create precise and intricate parts. This method offers several advantages over other casting processes, making it an essential technique in sectors like automotive, aerospace, electronics, and more. In this article, we will explore the key benefits of high pressure aluminum die casting, focusing on its importance, how it works, its impact on product quality, and its contribution to sustainable manufacturing practices.

1. What is High Pressure Aluminum Die Casting?

High pressure aluminum die casting is a manufacturing process where molten aluminum is injected into a mold under high pressure, filling the mold cavity quickly to form a solid, precise part. The molten aluminum is forced into the die with great speed and pressure, ensuring high accuracy and a smooth surface finish. This process is widely used to create complex shapes that would be difficult to achieve using other casting methods. The benefits include enhanced dimensional accuracy, a high degree of detail, and the ability to produce large quantities of parts at a faster rate.

What’s the real story? High pressure aluminum die casting is not just about speed—it’s about precision and quality. It is known for producing lightweight, durable components that require minimal post-processing. The rapid cooling of the aluminum allows for fine details and tight tolerances that are perfect for industries demanding high-quality, high-performance parts. The method also supports high-volume production, making it cost-effective for manufacturers producing large quantities of parts. This is especially true in the automotive sector, where die-cast aluminum components are used extensively in engine blocks, transmission housings, and more.

Table 1: Key Features of High Pressure Aluminum Die Casting

| Feature | Description |

|---|---|

| Precision | High accuracy with tight tolerances |

| Speed | Fast production cycles |

| Material Used | Molten aluminum |

| Applications | Automotive, aerospace, consumer electronics, etc. |

| Post-Processing Needs | Minimal post-processing required |

2. Why Choose High Pressure Aluminum Die Casting for Your Manufacturing Needs?

When it comes to choosing a casting method, high pressure aluminum die casting offers several compelling reasons to be the preferred option. It stands out because of its ability to produce high-precision parts with intricate details and complex shapes. Manufacturers in industries such as automotive and aerospace rely heavily on this process due to the superior strength and lightweight properties of aluminum.

Ready for the good part? High pressure aluminum die casting allows for faster production times, which translates to quicker time-to-market for new products. The mold cavity is filled under high pressure, which reduces cycle times and allows for higher productivity. Additionally, the ability to use aluminum, a highly versatile and recyclable material, makes this process environmentally friendly. The aluminum casting can also be recycled, which is a major benefit in reducing the carbon footprint of manufacturing processes.

The advantages don’t stop there. High pressure aluminum die casting allows for better material usage, minimizing waste. When the molten aluminum fills the mold, it’s closely controlled, ensuring only the necessary amount is used, which reduces scrap material. This efficiency not only helps to reduce costs but also supports sustainable manufacturing practices by cutting down on material waste and energy consumption.

Table 2: Advantages of High Pressure Aluminum Die Casting

| Advantage | Benefit |

|---|---|

| Speed | Faster production cycle times |

| Precision | Tight tolerances and intricate shapes |

| Material Efficiency | Reduced material waste and scrap |

| Sustainability | Recyclability of aluminum and reduced carbon footprint |

| Cost-Effectiveness | Lower cost per unit for high-volume production |

3. How Does High Pressure Aluminum Die Casting Work?

The high pressure aluminum die casting process begins with the preparation of a steel mold, also called a die, which is designed to form the desired shape of the part. The mold is preheated to ensure that the molten aluminum flows smoothly and fills the cavity without cooling too quickly. Once the die is ready, molten aluminum is poured into a chamber where it is injected into the mold cavity at high pressure. The aluminum cools rapidly, solidifying in the die to form the part.

But here’s the kicker—during this process, the mold cavity is filled with molten aluminum under very high pressure, often exceeding 10,000 psi. This intense pressure ensures that the aluminum fills every detail of the mold, ensuring precise and accurate reproduction of the mold’s features. The fast cooling process helps the material harden quickly, making it easy to remove the casting from the die without excessive distortion.

The machinery used in high pressure aluminum die casting includes automatic or semi-automatic die casting machines, which can operate at high speeds to inject molten aluminum into the die. These machines are equipped with sophisticated technology that controls the pressure, temperature, and speed at which the molten aluminum is injected into the mold, ensuring the highest levels of accuracy and consistency.

Table 3: Process Flow of High Pressure Aluminum Die Casting

| Step | Description |

|---|---|

| Die Preparation | Molds are designed, preheated, and coated for smooth flow |

| Injection | Molten aluminum is injected under high pressure |

| Cooling | Fast cooling to solidify the aluminum |

| Ejection | The solidified part is ejected from the die |

| Finishing | Any necessary post-processing is done |

4. What Are the Benefits of High Pressure Aluminum Die Casting for Your Business?

For businesses, the benefits of high pressure aluminum die casting extend far beyond the process itself. One of the biggest advantages is the ability to produce high-quality parts at a lower cost, especially when producing large volumes. The speed and efficiency of the casting process ensure that production times are minimized, which can significantly reduce manufacturing costs.

What’s the real story? Businesses benefit from the consistency and quality of high pressure aluminum die casting, which reduces the need for rework or costly post-production adjustments. This consistency is critical in industries where quality is paramount, such as automotive and aerospace manufacturing. Moreover, the lightweight yet durable nature of aluminum parts makes them perfect for use in demanding applications, allowing businesses to deliver high-performance products that meet customer expectations.

In addition, high pressure aluminum die casting allows manufacturers to produce parts with complex geometries that would be impossible to create using other methods. The intricate details and precision offered by this process open up new possibilities for product innovation and design.

Table 4: Business Benefits of High Pressure Aluminum Die Casting

| Benefit | Description |

|---|---|

| Cost Efficiency | Lower production costs for high-volume production |

| Consistency | High-quality parts with minimal defects |

| Product Innovation | Ability to create complex geometries |

| Durability | Lightweight and strong parts for demanding applications |

5. How Does High Pressure Aluminum Die Casting Improve Product Design?

High pressure aluminum die casting plays a pivotal role in enhancing product design, offering designers and engineers the ability to create parts with complex shapes, thin walls, and fine details that would be difficult or impossible to achieve using other manufacturing methods. This makes it an ideal choice for industries that require high precision and high-performance components.

Ready for the good part? One of the key benefits of high pressure aluminum die casting is that it allows designers to reduce part weight without sacrificing strength. The aluminum’s lightweight properties are ideal for industries such as automotive, where every gram saved can lead to improved fuel efficiency and performance. Moreover, the ability to create intricate parts means that designers have more flexibility when it comes to shaping their components, opening up new possibilities for innovation.

The process also allows for more efficient use of materials. The molds used in high pressure aluminum die casting are designed to maximize the material yield, reducing waste and keeping costs down. This is especially beneficial for large-scale production runs, where material savings can lead to significant reductions in overall manufacturing costs.

Table 5: How High Pressure Aluminum Die Casting Enhances Product Design

| Design Benefit | Description |

|---|---|

| Complex Geometries | Ability to create intricate parts with detailed features |

| Material Efficiency | Minimizes waste and maximizes material use |

| Weight Reduction | Lightweight yet strong components for high-performance |

| Design Flexibility | Increased possibilities for innovative designs |

6. What Industries Use High Pressure Aluminum Die Casting?

High pressure aluminum die casting is utilized across a wide variety of industries due to its ability to produce high-quality, lightweight, and durable parts. This method is especially beneficial in sectors where precision, reliability, and performance are key requirements. Automotive, aerospace, consumer electronics, and industrial machinery are just a few examples of industries that rely on this technique.

Here’s where it gets interesting—high pressure aluminum die casting is heavily used in the automotive industry for producing engine blocks, transmission housings, and other critical parts. The ability to create complex, lightweight components that can withstand high temperatures and pressures makes aluminum die casting a go-to choice for this sector. Aerospace also benefits from the lightweight and high-strength properties of aluminum, with parts like turbine blades, landing gear components, and structural elements being commonly cast through this process.

In addition to these, industries like telecommunications and consumer electronics frequently turn to high pressure aluminum die casting to produce high-performance parts for devices such as smartphones, laptops, and televisions. The precision and durability of the cast parts make them perfect for electronic enclosures, connectors, and housings.

The flexibility of this process allows it to be used in various other sectors as well, such as medical devices, robotics, and industrial machinery. As industries continue to demand more efficient and high-performance products, the role of high pressure aluminum die casting will only expand.

Table 6: Industries Using High Pressure Aluminum Die Casting

| Industry | Common Applications |

|---|---|

| Automotive | Engine blocks, transmission housings, wheel rims |

| Aerospace | Turbine blades, landing gear, structural components |

| Consumer Electronics | Smartphone housings, laptop parts, TV enclosures |

| Industrial Machinery | Pumps, valves, robotics components |

| Medical Devices | Surgical tools, diagnostic equipment housings |

7. What Are Some Common Challenges in High Pressure Aluminum Die Casting?

While high pressure aluminum die casting offers numerous benefits, it’s not without its challenges. Understanding these potential obstacles is crucial for manufacturers to maintain quality and efficiency in their operations. Some of the most common issues in this process include defects such as porosity, misruns, cold shuts, and flash. These defects can impact the integrity of the casting and lead to additional costs in post-production.

Porosity, for instance, refers to the formation of small air pockets or voids within the casting. This can weaken the final product and compromise its structural integrity. Misruns occur when the molten aluminum fails to fully fill the mold, leaving portions of the casting incomplete. Cold shuts happen when the molten metal cools too quickly and doesn’t fuse properly, leaving weak joints or seams. Flash, on the other hand, is excess metal that seeps out of the mold, creating unwanted burrs or extra material around the edges of the casting.

But here’s the kicker—there are solutions to each of these problems. Porosity can often be minimized through proper control of the injection process and the use of degassed molten aluminum. Misruns can be avoided by carefully designing the mold and ensuring the proper temperature and pressure during the injection phase. Cold shuts can be minimized by controlling the mold’s temperature and ensuring the molten metal is injected at the right speed. Flash can be controlled by ensuring the mold is tightly secured during injection, reducing the risk of excess material escaping.

By addressing these common challenges and implementing preventative measures, manufacturers can ensure that high pressure aluminum die casting remains a reliable and efficient process for producing high-quality components.

Table 7: Common Challenges and Solutions in High Pressure Aluminum Die Casting

| Challenge | Description | Solution |

|---|---|---|

| Porosity | Air pockets or voids inside the casting | Use degassed molten aluminum and control injection speed |

| Misruns | Incomplete mold filling due to low flow of molten metal | Optimize mold design and control injection temperature |

| Cold Shuts | Weak joints from improper fusion of molten metal | Maintain proper mold temperature and injection speed |

| Flash | Excess material leaking from the mold | Secure the mold tightly and control injection pressure |

8. How Can You Optimize the High Pressure Aluminum Die Casting Process?

Optimizing the high pressure aluminum die casting process can lead to significant improvements in product quality, production efficiency, and cost-effectiveness. The optimization process begins with the careful design of the molds and the management of the injection process. By ensuring that the mold is designed to minimize defects such as porosity or misruns, manufacturers can significantly improve the quality of the cast parts.

Ready for the good part? The use of advanced technologies such as automated systems, real-time monitoring, and machine learning can further enhance the process. Automated die casting machines can operate at faster speeds, reducing cycle times and increasing overall production rates. These machines can also monitor the pressure and temperature of the molten aluminum, making real-time adjustments to ensure that the process is optimized for the highest quality results.

In addition to automation, the use of simulation software can help optimize the design of the mold and the casting process before production begins. This software can predict the flow of molten metal, identify potential areas of weakness in the mold design, and suggest adjustments to improve casting quality. By testing different scenarios digitally, manufacturers can avoid costly trial-and-error processes and streamline the overall workflow.

The careful selection of aluminum alloys and other materials also plays a critical role in optimization. Using the right alloys for specific applications can enhance the performance and durability of the final product, ensuring that it meets the desired specifications for strength, weight, and thermal conductivity.

Table 8: Key Factors in Optimizing High Pressure Aluminum Die Casting

| Factor | Description |

|---|---|

| Mold Design | Ensure molds are designed to minimize defects |

| Automation | Use automated systems to reduce cycle times and improve precision |

| Simulation Software | Utilize digital simulations to optimize mold and process design |

| Material Selection | Choose the right alloys for improved performance and durability |

9. How Does High Pressure Aluminum Die Casting Contribute to Sustainability?

As industries increasingly focus on sustainability, high pressure aluminum die casting offers several environmental benefits that align with green manufacturing practices. The process itself is energy-efficient, using significantly less energy than many other metalworking methods. Moreover, aluminum is one of the most recyclable materials, making it an environmentally friendly option for manufacturers.

What’s the real story? Aluminum castings can be recycled repeatedly without degrading the material’s properties, which reduces the need for new raw materials and helps lower the overall environmental impact of the manufacturing process. By incorporating recycled aluminum into the die casting process, manufacturers can further reduce their carbon footprint and conserve natural resources.

Additionally, high pressure aluminum die casting generates minimal material waste, as the process uses precise amounts of molten metal to fill the molds. This efficiency not only helps reduce waste but also lowers costs for manufacturers by minimizing scrap material.

The process also supports other sustainability initiatives, such as reducing vehicle weight for improved fuel efficiency in the automotive industry. By using lightweight aluminum parts, manufacturers can help reduce the carbon emissions of the vehicles in which these parts are used, contributing to broader environmental goals.

Table 9: Sustainability Benefits of High Pressure Aluminum Die Casting

| Sustainability Benefit | Description |

|---|---|

| Energy Efficiency | Consumes less energy than many other manufacturing processes |

| Recyclability | Aluminum can be recycled repeatedly without quality loss |

| Material Efficiency | Minimizes material waste during production |

| Carbon Footprint Reduction | Reduces emissions through lightweight, durable parts |

10. What Are the Design Considerations for High Pressure Aluminum Die Casting?

When designing parts for high pressure aluminum die casting, several factors must be considered to ensure the success of the process. One of the key considerations is wall thickness. In aluminum die casting, thinner walls are generally preferred as they result in lighter, stronger parts. However, it’s important to balance thin walls with the need for durability, as overly thin walls can compromise the strength of the part.

But here’s the kicker—tolerances also play a crucial role in ensuring that the final part meets the desired specifications. Tight tolerances are essential in industries like aerospace and automotive, where parts must fit together precisely to function correctly. In addition to tolerances, surface finish is another important consideration. High-quality surface finishes are essential for components that will be used in visible areas, such as consumer electronics or automotive exteriors.

Another consideration is the ease of casting, which involves designing parts that can be easily removed from the mold without causing damage. Complex shapes with undercuts or intricate features may require additional steps or tools to ensure the casting can be ejected smoothly. The complexity of the mold design is also a critical factor, as more intricate molds require higher precision and can increase the cost of production.

Table 10: Key Design Considerations for High Pressure Aluminum Die Casting

| Design Factor | Consideration |

|---|---|

| Wall Thickness | Balance between lightweight design and part strength |

| Tolerances | Tight tolerances for precise fitting of parts |

| Surface Finish | High-quality finishes for visible components |

| Ease of Casting | Avoid undercuts and ensure smooth mold ejection |

| Mold Complexity | Complex molds require higher precision and cost |

11. What Are the Most Common Defects in High Pressure Aluminum Die Casting?

High pressure aluminum die casting, while efficient and precise, does have some common defects that manufacturers need to be aware of. Addressing these defects early in the process can prevent costly mistakes and ensure the production of high-quality components. The most common defects include porosity, misruns, cold shuts, and flash.

Porosity is one of the most frequently encountered issues. It occurs when air pockets are trapped inside the casting, leading to weak spots in the part. This can affect the structural integrity of the final product and may require rework or rejection of the part. Misruns happen when the molten aluminum doesn’t completely fill the mold, leaving parts of the casting incomplete. This often occurs if the injection speed is too slow or the mold temperature is too low. Cold shuts occur when the molten aluminum cools too quickly before the two streams of molten metal meet, leading to weak joints and poor fusion.

Flash is another common defect in die casting. It occurs when excess molten metal leaks out of the mold during the injection process, causing unwanted material to spill over the edges of the casting. This can result in additional post-processing to remove the excess metal, adding time and cost to production.

What’s the real story? These defects can be minimized or eliminated with careful attention to the design of the mold, temperature control during the injection process, and monitoring the speed and pressure at which the molten aluminum is injected into the die. High-quality aluminum alloy and proper maintenance of the die casting machine can also help reduce the likelihood of defects, ensuring that parts meet the required standards for strength, durability, and appearance.

Table 11: Common Defects in High Pressure Aluminum Die Casting and Solutions

| Defect | Description | Solution |

|---|---|---|

| Porosity | Air pockets trapped inside the casting, weakening the part | Use degassed aluminum, optimize injection speed and pressure |

| Misruns | Incomplete mold filling due to insufficient flow of molten metal | Adjust mold temperature, increase injection speed |

| Cold Shuts | Weak joints due to molten metal not fusing properly | Control mold temperature and injection speed |

| Flash | Excess molten metal leaking from the mold | Ensure mold is tightly secured during injection |

12. How Do You Choose the Right High Pressure Aluminum Die Casting Supplier?

Choosing the right supplier for high pressure aluminum die casting is critical for the success of your project. With so many options available, it’s essential to consider several factors when making a decision. The first and most important consideration is the supplier’s experience in die casting. Suppliers with a proven track record in producing high-quality parts for industries like automotive, aerospace, and electronics are more likely to meet your specific requirements.

What’s the real story? Certification and quality control standards should be non-negotiable. Ensure that the supplier complies with international standards, such as ISO 9001, to guarantee that the parts are produced to the highest quality levels. Additionally, you should inquire about the supplier’s capabilities in terms of production volume, lead times, and their ability to handle custom designs. A reliable supplier should be able to meet your production needs while ensuring on-time delivery.

The supplier’s technical expertise is another key factor to consider. The best die casting suppliers employ skilled engineers who can assist with mold design, material selection, and process optimization. They should be able to provide solutions for any challenges that arise during the production process and ensure that the final product meets your specifications.

Table 12: Factors to Consider When Choosing a High Pressure Aluminum Die Casting Supplier

| Factor | Consideration |

|---|---|

| Experience | Look for a supplier with proven experience in your industry |

| Certifications | Ensure compliance with international quality standards like ISO 9001 |

| Production Capacity | Assess the supplier’s ability to meet your volume and lead time requirements |

| Technical Expertise | The supplier should offer engineering support and process optimization |

| Reliability | Choose a supplier with a strong reputation for on-time delivery and quality |

13. What Is the Future of High Pressure Aluminum Die Casting?

The future of high pressure aluminum die casting looks promising, with ongoing advancements in technology and materials making this process even more efficient and precise. Automation plays a key role in the future of aluminum die casting, with machines becoming more advanced and capable of handling higher speeds, more complex designs, and real-time monitoring of the casting process.

What’s the real story? Advances in materials are also driving change. New aluminum alloys with improved properties, such as higher strength, better corrosion resistance, and enhanced thermal conductivity, are becoming available. These new materials allow for even better performance of die-cast parts, expanding the potential applications of this process.

In addition, the rise of 3D printing and additive manufacturing is influencing die casting. While 3D printing is still in its early stages in terms of full-scale production, it can be used to design more efficient molds for die casting. By combining additive manufacturing with traditional die casting methods, manufacturers can produce parts that are both highly complex and cost-effective.

As industries continue to push the boundaries of product design, high pressure aluminum die casting will continue to evolve. Whether it’s producing lightweight parts for electric vehicles, creating more durable components for aerospace, or advancing new technology for consumer electronics, the future of this casting method is bright.

Table 13: Future Trends in High Pressure Aluminum Die Casting

| Trend | Description |

|---|---|

| Automation | Increased use of automated systems for faster and more precise production |

| Advanced Materials | New aluminum alloys offering better performance |

| 3D Printing and Additive Manufacturing | Use of 3D printing for mold design and process optimization |

| Electric Vehicles | Rising demand for lightweight, high-strength parts for electric vehicles |

| Aerospace Applications | Increasing use of die-cast aluminum in high-performance aerospace components |

14. How Can High Pressure Aluminum Die Casting Help Your Business Grow?

High pressure aluminum die casting can be a powerful tool for businesses looking to scale production while maintaining high-quality standards. The speed and efficiency of this casting process make it ideal for high-volume manufacturing, allowing businesses to meet growing demand without sacrificing precision or quality. By reducing production times and costs, businesses can increase profitability while improving their product offerings.

What’s the real story? The ability to create complex parts with minimal post-processing means that businesses can offer more innovative and detailed products. This is especially important in industries where performance and reliability are key, such as in the automotive or aerospace sectors. By investing in high pressure aluminum die casting, companies can differentiate themselves from competitors by offering superior products that meet customer demands for durability, performance, and design.

Moreover, the lightweight nature of aluminum die cast components is a significant advantage in industries like automotive and transportation. With increasing pressure to reduce vehicle weight for better fuel efficiency and lower emissions, the demand for aluminum die-cast parts will continue to rise. By adopting this process, businesses can stay ahead of the curve and cater to this growing market.

Table 14: How High Pressure Aluminum Die Casting Can Support Business Growth

| Benefit | Description |

|---|---|

| Increased Production Capacity | High-speed production to meet rising demand |

| Cost Reduction | Lower production costs due to efficient processes |

| Enhanced Product Innovation | Ability to create complex, innovative product designs |

| Market Competitiveness | Provides a competitive edge with lightweight, durable parts |

| Industry Adaptation | Meeting the growing demand for electric vehicle components and more |

15. What Are the Cost Implications of High Pressure Aluminum Die Casting?

Cost is always a major factor in choosing the right manufacturing method, and high pressure aluminum die casting offers a range of cost benefits. Initially, the tooling costs can be higher than other casting methods due to the complexity of the molds. However, these costs are quickly offset by the speed and efficiency of the casting process, especially in high-volume production runs.

What’s the real story? The efficiency of high pressure aluminum die casting results in reduced material waste, which helps to lower overall production costs. Additionally, the high precision of the process reduces the need for extensive post-production work, further cutting down costs. For manufacturers producing large quantities of parts, this cost-effectiveness becomes even more apparent as economies of scale kick in.

While the initial investment in die casting machines and molds may be significant, the long-term savings make this method highly cost-effective for large-scale production. When considering the cost of materials, labor, and time, high pressure aluminum die casting remains one of the most economical options for producing high-quality, durable parts.

Table 15: Cost Implications of High Pressure Aluminum Die Casting

| Cost Factor | Impact |

|---|---|

| Tooling Costs | Higher initial investment due to mold complexity |

| Material Waste | Reduced waste due to precision casting |

| Production Speed | Faster production times leading to lower labor costs |

| Post-Processing | Minimal post-processing required, reducing overall costs |

| Long-Term Savings | Cost-effective for high-volume production runs |

FAQ Section

Q1: What is high pressure aluminum die casting?

High pressure aluminum die casting is a process where molten aluminum is injected into molds under high pressure to create precise, intricate parts. It’s commonly used in industries like automotive, aerospace, and electronics.

Q2: How does high pressure aluminum die casting improve product design?

The process allows for the creation of complex shapes, intricate details, and lightweight yet durable components, providing designers with greater flexibility and innovation opportunities.

Q3: What are the benefits of high pressure aluminum die casting for businesses?

High pressure aluminum die casting offers faster production times, reduced material waste, and high consistency in product quality, making it a cost-effective choice for large-scale manufacturing.

Q4: How does high pressure aluminum die casting contribute to sustainability?

The process is energy-efficient, uses recyclable aluminum, and minimizes material waste, contributing to a more sustainable manufacturing process.

Q5: How does high pressure aluminum die casting work?

Molten aluminum is injected into a mold under high pressure, filling the mold cavity rapidly. The aluminum cools and solidifies, forming a precise part that can be ejected and finished with minimal post-processing.