Introduction

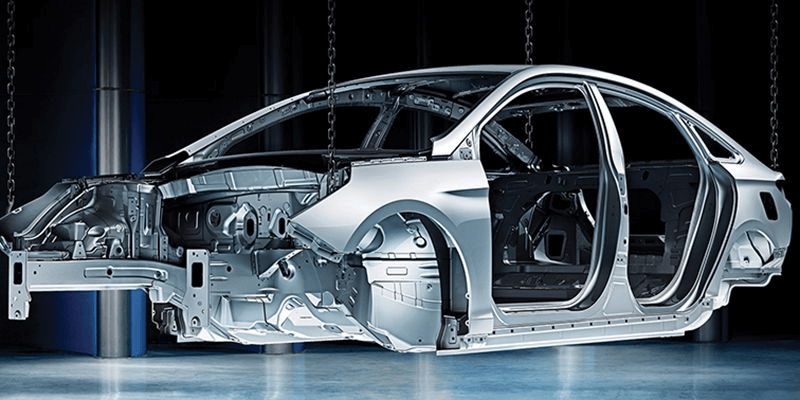

When it comes to the automotive industry, the choice of materials used in manufacturing is critical. From the engine to the braking system, every part of a vehicle needs to be made from materials that can withstand the demands of daily use. One material that stands out for its strength and durability is high carbon steel. In this article, we’ll explore the various automobile parts made from high carbon steel, diving deep into why this material is chosen for specific components. Whether you’re an automotive enthusiast, a technician, or just someone curious about what goes into making your vehicle, this comprehensive guide will provide valuable insights.

Brief Overview of High Carbon Steel

High carbon steel is a type of steel where the carbon content ranges between 0.6% and 1.0%. This increased carbon content gives the steel its characteristic hardness and strength, making it ideal for applications where wear resistance and durability are essential. Unlike low and medium carbon steels, high carbon steel is less ductile but offers superior hardness and strength. This makes it particularly suited for certain automobile parts where these properties are crucial.

Importance of Material Selection in the Automotive Industry

The automotive industry is a highly competitive field where safety, performance, and durability are paramount. Every component of a vehicle must be carefully designed and manufactured to ensure it meets stringent safety standards while also delivering optimal performance. The choice of material plays a crucial role in this. For instance, while aluminum may be favored for its lightweight properties, steel, particularly high carbon steel, is often chosen for parts that require high strength and durability. The right material can mean the difference between a car that performs well and one that fails under stress.

Purpose of the Article

This article aims to educate readers on the specific car parts made from high carbon steel. We will explore why this material is chosen for certain components over others, how it benefits the overall performance of the vehicle, and what makes it indispensable in automotive manufacturing. By the end of this article, you’ll have a thorough understanding of the role high carbon steel plays in your vehicle and why it’s a preferred material for various automobile parts.

Understanding High Carbon Steel

What is High Carbon Steel?

High carbon steel is a versatile and robust material characterized by its high carbon content, typically between 0.6% and 1.0%. This elevated carbon percentage gives the steel distinct properties that differentiate it from other forms of steel, such as low and medium carbon steel. The primary feature of high carbon steel is its hardness, which makes it incredibly resistant to wear and tear. This hardness is a double-edged sword; while it enhances durability, it also reduces the material’s ductility, making it less flexible and more prone to cracking under certain conditions.

High carbon steel’s unique composition also makes it less malleable and more challenging to weld, requiring specialized techniques and equipment. However, its strength and ability to withstand high stress make it an ideal choice for parts that experience significant wear and need to maintain their integrity over time.

Key Properties of High Carbon Steel

High carbon steel boasts several key properties that make it suitable for specific applications in the automotive industry:

- Hardness: The primary attribute of high carbon steel is its exceptional hardness. This property is crucial for components that need to resist deformation under stress, such as gears and axles. The hardness also contributes to the steel’s wear resistance, making it ideal for parts subjected to constant friction.

- Tensile Strength: High carbon steel has a high tensile strength, meaning it can withstand significant force without breaking. This is particularly important in car parts like suspension springs and brake components, which must endure high stress and loads.

- Wear Resistance: Thanks to its hardness, high carbon steel is highly resistant to wear, making it perfect for components that experience constant friction and contact, such as brake rotors and gears. This resistance ensures a longer lifespan for parts, reducing the need for frequent replacements.

- Heat Treatment Potential: High carbon steel can undergo various heat treatment processes, such as annealing, quenching, and tempering, to enhance its properties. Heat treatment can significantly increase the steel’s hardness and strength, making it even more suitable for high-stress applications.

Advantages and Disadvantages

Like any material, high carbon steel has its advantages and disadvantages, which must be carefully considered when selecting it for automotive applications.

Advantages:

- Durability: High carbon steel is incredibly durable, making it ideal for components that need to withstand high stress and frequent use. This durability translates to longer-lasting parts, reducing the frequency of replacements and maintenance.

- High Wear Resistance: The material’s hardness and wear resistance make it perfect for parts that experience constant friction, such as brake rotors and gears. This property ensures that the parts maintain their shape and functionality over time, even under extreme conditions.

- Enhanced Performance Through Heat Treatment: High carbon steel can be heat-treated to enhance its properties further, allowing manufacturers to tailor the material to specific applications. This flexibility makes it a versatile choice for various car parts.

Disadvantages:

- Brittleness: While high carbon steel is incredibly hard, this hardness comes at the cost of brittleness. The material is more prone to cracking or breaking under impact, which can be a significant drawback in some applications.

- Difficulty in Welding: The high carbon content makes the steel more challenging to weld, requiring specialized techniques and equipment. This can increase manufacturing costs and complexity.

- Limited Ductility: High carbon steel is less ductile than other forms of steel, meaning it can’t be easily shaped or formed without risking cracking or breaking. This limitation must be considered when designing and manufacturing parts.

Common Uses of High Carbon Steel in Various Industries

High carbon steel’s properties make it suitable for a wide range of applications beyond the automotive industry. It is commonly used in the production of tools, such as knives, blades, and cutting instruments, where its hardness and wear resistance are critical. The construction industry also utilizes high carbon steel for components like drill bits and masonry nails, which need to maintain their shape and sharpness over time.

In the automotive industry, high carbon steel is often chosen for components that require high strength, wear resistance, and durability. These include parts like brake rotors, gears, and suspension springs, where the material’s properties are essential for ensuring the vehicle’s performance and safety.

Automotive Industry’s Material Needs

Why Material Choice Matters in Cars

In the automotive industry, the choice of material for each component is not just a technical decision; it’s a critical factor that can significantly impact the vehicle’s overall performance, safety, and longevity. Every part of a car is subjected to various stresses, including mechanical forces, thermal expansion, and exposure to environmental factors such as moisture and corrosive elements. Therefore, selecting the right material is essential to ensure that each part can withstand these challenges without compromising the vehicle’s functionality or safety.

For example, materials chosen for the engine and transmission must endure high temperatures and mechanical loads, while those used in the body must resist corrosion and provide structural integrity. In this context, high carbon steel emerges as a vital material due to its ability to meet the stringent requirements of several critical automotive components.

Commonly Used Materials in the Automotive Industry

The automotive industry relies on a variety of materials, each selected for its specific properties that best suit different parts of a vehicle:

- Steel: The most widely used material in car manufacturing, steel is valued for its strength, durability, and cost-effectiveness. Different types of steel, including high carbon steel, are used for various parts, depending on the required properties.

- Aluminum: Known for its lightweight and corrosion-resistant properties, aluminum is often used in the production of engine components, wheels, and body panels. Its lightweight nature helps improve fuel efficiency and reduce overall vehicle weight.

- Carbon Fiber: A high-strength, lightweight material, carbon fiber is commonly used in high-performance vehicles. It offers excellent strength-to-weight ratios but is more expensive than other materials.

- Plastics and Composites: These materials are used extensively in the automotive industry for components that require flexibility, light weight, and resistance to corrosion. Examples include interior components, bumper covers, and fuel tanks.

- Rubber: Rubber is primarily used for tires, seals, and gaskets, where flexibility and resilience are essential.

The Role of High Carbon Steel in Car Manufacturing

High carbon steel plays a crucial role in car manufacturing due to its unique combination of hardness, strength, and wear resistance. These properties make it an ideal material for parts that are subjected to high stress and require long-lasting durability. Unlike materials like aluminum or plastics, which are chosen for their lightweight or flexible properties, high carbon steel is selected when toughness and resistance to wear are paramount.

In applications where components need to maintain their shape and function under extreme conditions—such as high temperatures, mechanical stress, or friction—high carbon steel is often the material of choice. Its ability to undergo heat treatment processes further enhances its suitability for such demanding applications, ensuring that the parts perform reliably over the vehicle’s lifespan.

Car Parts Made of High Carbon Steel

Braking System Components

Brake Rotors and Discs

Brake rotors and discs are among the most critical components in a vehicle’s braking system, directly influencing stopping power and safety. These parts are typically made from high carbon steel due to the material’s excellent wear resistance and ability to withstand high temperatures generated during braking.

High carbon steel’s hardness ensures that the brake rotors maintain their structural integrity even after prolonged use, reducing the likelihood of warping or cracking. This is particularly important because brake rotors experience extreme friction and heat every time the brakes are applied. The material’s ability to dissipate heat effectively helps prevent overheating, which can lead to brake fade—a condition where the braking power is significantly reduced due to excessive heat.

The choice of high carbon steel for brake rotors and discs also enhances the overall braking performance, providing a more consistent and reliable braking experience. This is why high carbon steel is favored in high-performance and heavy-duty vehicles, where the demands on the braking system are even greater.

Brake Pads

While the friction material of brake pads is typically made from composites or ceramics, the backing plates of brake pads are often made from high carbon steel. The backing plate serves as the foundation for the friction material and must be strong enough to withstand the mechanical forces applied during braking.

High carbon steel’s strength and hardness make it ideal for this application, ensuring that the brake pads remain securely attached to the caliper and continue to perform effectively over time. The material’s wear resistance also means that the backing plates are less likely to deform, even under the high-pressure conditions experienced during braking.

Suspension System Components

Springs

Suspension springs are vital components that absorb shocks and maintain vehicle stability by keeping the tires in contact with the road. These springs must be strong enough to support the vehicle’s weight while also being flexible enough to absorb road irregularities. High carbon steel is often used for suspension springs due to its excellent tensile strength and resilience.

The high carbon content in the steel allows the springs to maintain their shape and performance over long periods, even under constant stress. This is crucial for ensuring a smooth ride and consistent handling characteristics. Additionally, the material’s resistance to wear and fatigue helps prolong the lifespan of the suspension system, reducing the need for frequent replacements and maintenance.

High carbon steel’s ability to be heat-treated also plays a significant role in enhancing the performance of suspension springs. By carefully controlling the heat treatment process, manufacturers can increase the hardness and strength of the steel, making it even more suitable for the demanding conditions faced by suspension components.

Transmission Components

Gears

Gears are essential components in a vehicle’s transmission system, responsible for transferring power from the engine to the wheels. These parts must withstand high levels of stress and wear, making high carbon steel an ideal material for their construction.

The hardness and strength of high carbon steel ensure that the gears can endure the repeated stress of transmitting power without deforming or wearing out prematurely. This is particularly important in high-performance vehicles, where the transmission system is subjected to extreme forces.

High carbon steel’s wear resistance also helps maintain the precision and efficiency of the transmission system, ensuring smooth gear changes and consistent performance. Additionally, the material’s ability to undergo heat treatment allows manufacturers to enhance the properties of the gears further, making them even more durable and reliable.

Axles

Axles are another critical component in a vehicle’s drivetrain, responsible for transferring power from the transmission to the wheels. Like gears, axles must withstand significant stress and mechanical loads, making high carbon steel an ideal material for their construction.

The strength and durability of high carbon steel ensure that the axles can handle the torque generated by the engine without bending or breaking. This is especially important in heavy-duty and high-performance vehicles, where the demands on the drivetrain are even greater.

High carbon steel’s wear resistance also contributes to the longevity of the axles, reducing the need for frequent replacements and ensuring consistent performance over the vehicle’s lifespan.

Engine Components

Piston Rings

Piston rings are small yet crucial components in an engine, responsible for sealing the combustion chamber and preventing oil from leaking into the combustion area. These rings must withstand high temperatures and pressures, making high carbon steel an ideal material for their construction.

The hardness and wear resistance of high carbon steel ensure that the piston rings maintain a tight seal, even under the extreme conditions inside the engine. This is essential for maintaining engine efficiency and preventing oil consumption, which can lead to increased emissions and reduced performance.

High carbon steel’s ability to resist wear also helps prolong the lifespan of the piston rings, reducing the need for frequent replacements and ensuring that the engine continues to perform optimally.

Valve Springs

Valve springs are another critical engine component, responsible for maintaining the tension on the valves and ensuring that they open and close at the correct times. These springs must be strong enough to withstand the constant stress of opening and closing the valves while also being flexible enough to absorb shocks.

High carbon steel is often used for valve springs due to its excellent tensile strength and fatigue resistance. The material’s ability to maintain its shape and performance under constant stress is crucial for ensuring that the engine continues to run smoothly and efficiently.

Additionally, high carbon steel’s resistance to wear and fatigue helps prolong the lifespan of the valve springs, reducing the need for frequent replacements and maintenance.

Miscellaneous Components

Bearings and Bushings

Bearings and bushings are essential components in a vehicle’s drivetrain and suspension system, responsible for reducing friction and wear between moving parts. High carbon steel is often used for these components due to its excellent wear resistance and durability.

The hardness of high carbon steel ensures that the bearings and bushings maintain their shape and function over time, even under the constant stress of rotating or sliding parts. This is crucial for ensuring the smooth operation of the drivetrain and suspension system, reducing friction and wear, and prolonging the lifespan of the vehicle.

Cutting Tools Used in Manufacturing

High carbon steel is not only used in the construction of automobile parts but also in the tools used to manufacture these parts. Cutting tools, such as drill bits, saw blades, and milling cutters, are often made from high carbon steel due to its hardness and wear resistance.

The ability of high carbon steel to maintain a sharp edge and resist wear is crucial for ensuring that the tools can cut through other materials with precision and efficiency. This is particularly important in the automotive industry, where precision and consistency are essential for producing high-quality parts.

Why High Carbon Steel is Chosen Over Other Materials

Comparative Analysis

When selecting materials for automobile parts, manufacturers must consider various factors, including strength, durability, cost, and performance. High carbon steel is often chosen over other materials, such as low and medium carbon steel, aluminum, and alloys, due to its unique combination of properties.

Compared to low and medium carbon steel, high carbon steel offers superior hardness and wear resistance, making it ideal for parts that experience high stress and friction. While aluminum and alloys are favored for their lightweight properties, they cannot match the strength and durability of high carbon steel, making it the preferred choice for components that require maximum toughness and longevity.

Cost-Effectiveness

One of the key reasons why high carbon steel is favored in the automotive industry is its cost-effectiveness. Despite its superior properties, high carbon steel is relatively inexpensive compared to other high-performance materials, such as titanium or carbon fiber. This makes it an attractive option for manufacturers who need to produce durable and reliable parts without significantly increasing costs.

High carbon steel’s ability to undergo heat treatment processes also adds to its cost-effectiveness. By carefully controlling the heat treatment, manufacturers can enhance the material’s properties, making it even more suitable for specific applications without the need for more expensive materials.

Performance Under Stress

High carbon steel is chosen for automobile parts that need to perform reliably under high stress and extreme conditions. Whether it’s the constant friction experienced by brake rotors or the mechanical loads on transmission gears, high carbon steel’s hardness and strength ensure that these parts can withstand the demands placed on them without failing.

The material’s ability to maintain its performance under stress is crucial for ensuring the safety and reliability of the vehicle. For example, the use of high carbon steel in suspension springs helps maintain vehicle stability, while its use in gears and axles ensures smooth and efficient power transfer.

Case Studies

Several real-world examples highlight the advantages of using high carbon steel in automobile parts:

- High-Performance Brake Systems: In high-performance vehicles, where braking power is critical, high carbon steel brake rotors are often used to ensure maximum stopping power and reliability. The material’s wear resistance and ability to dissipate heat effectively make it ideal for this application.

- Heavy-Duty Truck Axles: In heavy-duty trucks, where the drivetrain is subjected to extreme stress, high carbon steel axles are used to ensure that the vehicle can handle heavy loads without bending or breaking. The material’s strength and durability are crucial for maintaining the truck’s performance and safety.

- Racing Car Suspension Springs: In racing cars, where suspension performance is critical for handling and stability, high carbon steel springs are used to ensure that the vehicle can maintain its performance under extreme conditions. The material’s resilience and fatigue resistance are essential for ensuring consistent performance over time.

Manufacturing Processes for High Carbon Steel Car Parts

Forging and Casting

Forging and casting are two common manufacturing processes used to shape high carbon steel into automobile parts. Each process has its advantages and is chosen based on the specific requirements of the part being produced.

Forging: Forging involves shaping high carbon steel by applying compressive forces, usually through hammering or pressing. This process enhances the material’s grain structure, resulting in increased strength and toughness. Forging is often used for parts that need to withstand high stress, such as gears, axles, and suspension springs. The controlled deformation during forging helps eliminate internal defects, making the parts more reliable and durable.

Casting: Casting involves pouring molten high carbon steel into a mold to create the desired shape. This process is suitable for complex shapes and large components that would be difficult to produce through forging. Casting is commonly used for parts like brake rotors and engine components, where the precise shape and dimensions are crucial for performance. While casting may introduce some internal porosity, careful control of the process can minimize defects and ensure the part’s integrity.

Heat Treatment

Heat treatment is a crucial step in the manufacturing of high carbon steel parts, allowing manufacturers to enhance the material’s properties and tailor it to specific applications. The heat treatment process involves heating the steel to a specific temperature, holding it at that temperature for a set period, and then cooling it in a controlled manner.

Hardening: Hardening involves heating high carbon steel to a high temperature and then rapidly cooling it, usually in water or oil. This process increases the steel’s hardness and wear resistance, making it ideal for parts that need to withstand high stress and friction. However, hardening can also increase the material’s brittleness, so it is often followed by tempering.

Tempering: Tempering is a heat treatment process that follows hardening, where the steel is heated to a lower temperature and then slowly cooled. This process reduces the brittleness introduced by hardening while maintaining the material’s hardness and strength. Tempering is essential for ensuring that high carbon steel parts, such as gears and axles, can withstand impact and stress without breaking.

Annealing: Annealing involves heating the steel to a specific temperature and then cooling it slowly. This process softens the steel, making it easier to work with and reducing internal stresses. Annealing is often used for parts that need to be machined or formed before final heat treatment.

Machining Challenges and Solutions

Machining high carbon steel presents several challenges due to the material’s hardness and wear resistance. The high carbon content makes the steel difficult to cut and shape, leading to increased tool wear and longer machining times. However, these challenges can be overcome with the right techniques and equipment.

Tool Selection: Using high-quality, wear-resistant cutting tools, such as carbide or ceramic tools, is essential for machining high carbon steel. These tools can withstand the hardness of the material and maintain a sharp edge for longer periods, reducing tool wear and improving machining efficiency.

Cooling and Lubrication: Effective cooling and lubrication are crucial during the machining of high carbon steel to prevent overheating and tool wear. Using high-pressure coolant systems and appropriate cutting fluids can help reduce friction and heat, ensuring smoother cuts and extending tool life.

Precision and Control: Precision machining techniques, such as CNC (Computer Numerical Control) machining, allow for greater control over the cutting process, ensuring that high carbon steel parts are shaped with high accuracy and consistency. This is particularly important for parts like gears and engine components, where precision is critical for performance.

Challenges and Limitations of Using High Carbon Steel

Brittleness and Fracture Risks

One of the primary challenges of using high carbon steel is its brittleness, which increases the risk of fracture under certain conditions. The high carbon content, while contributing to the material’s hardness and wear resistance, also makes it less ductile and more prone to cracking under impact. This brittleness is particularly concerning in applications where parts are subjected to sudden shocks or impacts, such as in suspension components or crash-sensitive areas of the vehicle.

To mitigate these risks, manufacturers often employ tempering as part of the heat treatment process. Tempering reduces brittleness while maintaining the steel’s hardness, striking a balance between strength and ductility. In critical applications, such as in safety-related components, additional design considerations and material selection criteria are employed to ensure that the risk of fracture is minimized.

Corrosion Resistance

High carbon steel, like most forms of steel, is susceptible to corrosion, particularly when exposed to moisture and corrosive environments. This limitation can be a significant drawback in automotive applications, where parts are frequently exposed to water, salt, and other corrosive elements. Without proper protection, high carbon steel parts can rust, leading to weakened structural integrity and reduced lifespan.

To combat corrosion, high carbon steel parts are often coated with protective layers, such as zinc plating, painting, or applying corrosion-resistant alloys. In some cases, the steel is alloyed with elements like chromium or nickel to enhance its corrosion resistance. Regular maintenance and the use of corrosion inhibitors can also help extend the lifespan of high carbon steel parts in automotive applications.

Weight Considerations

While high carbon steel offers exceptional strength and durability, it is also heavier than many alternative materials, such as aluminum or composites. This additional weight can impact vehicle performance, particularly in terms of fuel efficiency and handling. In the automotive industry, where weight reduction is a critical factor in improving fuel economy and reducing emissions, the heavier nature of high carbon steel can be a disadvantage.

To address this issue, manufacturers must carefully balance the need for strength and durability with the desire to reduce weight. In some cases, high carbon steel may be used selectively in areas where its properties are most needed, while lighter materials are used in other parts of the vehicle. This approach allows for the benefits of high carbon steel without excessively compromising the vehicle’s overall weight.

Future Trends in Material Selection for Car Parts

Advancements in Steel Technology

The automotive industry continues to evolve, with ongoing research and development efforts aimed at improving materials used in vehicle manufacturing. In the realm of steel technology, advancements are being made to enhance the properties of high carbon steel, making it even more suitable for automotive applications.

One area of focus is the development of ultra-high-strength steels (UHSS), which offer even greater strength and durability while potentially reducing the brittleness associated with traditional high carbon steel. These new steel alloys are designed to provide the same wear resistance and hardness while improving ductility and impact resistance. As these technologies mature, we may see an increased use of UHSS in critical automotive components, offering a new level of performance and safety.

Alternative Materials

While high carbon steel remains a popular choice for many automotive parts, the industry is also exploring alternative materials that offer different benefits. Materials such as carbon fiber, titanium, and advanced composites are gaining traction, particularly in high-performance and luxury vehicles. These materials offer the advantage of being lighter than steel while still providing excellent strength and durability.

However, these alternatives often come with higher costs, making them less feasible for mass-market vehicles. As manufacturing processes for these materials become more cost-effective, we may see a broader adoption of alternative materials in various automotive applications. The challenge for manufacturers will be to strike the right balance between cost, performance, and sustainability.

Sustainability Considerations

Sustainability is becoming an increasingly important factor in material selection for the automotive industry. As environmental regulations tighten and consumer demand for eco-friendly vehicles grows, manufacturers are under pressure to choose materials that not only perform well but also have a lower environmental impact.

Recycling plays a significant role in the sustainability of high carbon steel. Steel is one of the most recyclable materials, and the ability to recycle high carbon steel without significant loss of quality makes it an attractive option from an environmental perspective. In the future, we can expect to see more emphasis on the use of recycled materials in automotive manufacturing, along with the development of new steel alloys that are both high-performing and environmentally friendly.

Conclusion

Summary of Key Points

High carbon steel is an essential material in the automotive industry, offering a unique combination of hardness, strength, and wear resistance that makes it ideal for a variety of car parts. From brake rotors and gears to suspension springs and axles, high carbon steel is used in critical components that need to withstand high stress and extreme conditions. While the material does have some limitations, such as brittleness and susceptibility to corrosion, these challenges can be managed through careful design, manufacturing processes, and protective measures.

The Future of High Carbon Steel in the Automotive Industry

As the automotive industry continues to innovate, high carbon steel will likely remain a vital material for many applications. Ongoing advancements in steel technology, along with the exploration of alternative materials, will shape the future of material selection in vehicle manufacturing. However, the durability, cost-effectiveness, and performance of high carbon steel ensure that it will continue to play a significant role in the production of automobile parts.

Final Thoughts

Understanding the materials used in automotive manufacturing is crucial for anyone involved in the industry, from engineers and technicians to procurement specialists and general managers. High carbon steel, with its exceptional properties, remains a cornerstone of automotive engineering, ensuring that vehicles are safe, reliable, and built to last. As we look to the future, the continued evolution of materials science will undoubtedly lead to new innovations, but high carbon steel’s legacy in the automotive industry is secure.

We invite you to share your thoughts or experiences with high carbon steel in automotive applications. Whether you’ve worked with this material in manufacturing or have insights into its performance in vehicles, we’d love to hear from you. Your contributions can help further the conversation and deepen our collective understanding of this critical material.