I. Introduction

A. Brief Overview of Carbon Steel and Its Applications

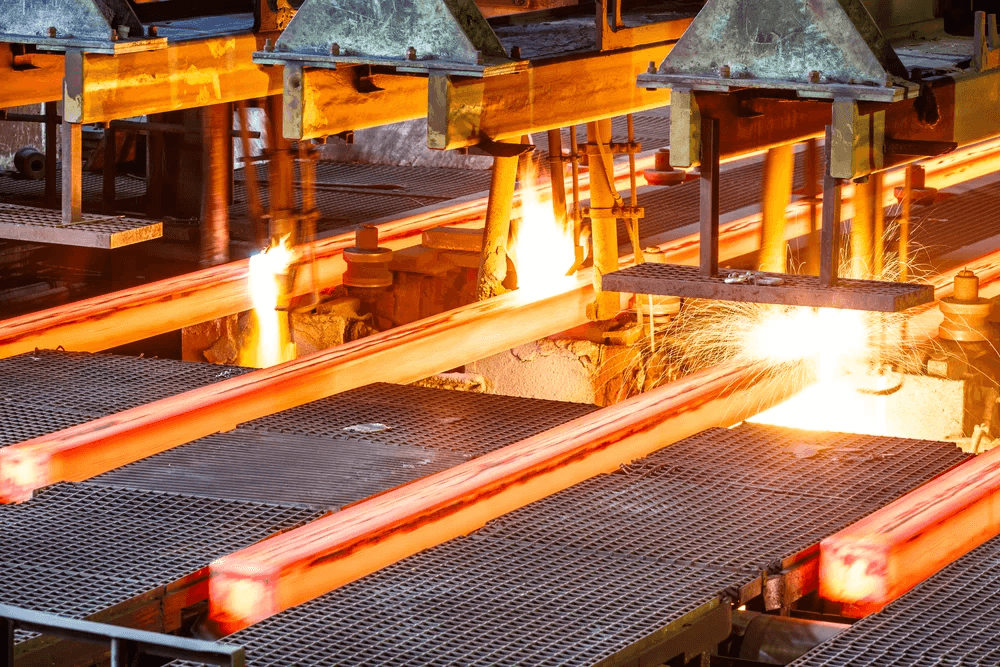

Carbon steel is a critical material in various industries due to its versatility, cost-effectiveness, and mechanical properties. As one of the most widely used materials in manufacturing, carbon steel plays a significant role in everything from infrastructure and construction to automotive and industrial machinery. The term “carbon steel” broadly refers to a category of steel where carbon is the primary alloying element, making up a significant portion of the material’s composition. The specific properties of carbon steel, such as its strength, hardness, and ductility, are largely determined by the amount of carbon present.

In the context of manufacturing, one of the most common applications of carbon steel is in the process of casting. Custom carbon steel casting allows manufacturers to produce complex shapes and components that meet specific mechanical and dimensional requirements. This process is especially valuable in industries where components must be durable, strong, and capable of withstanding significant wear and tear. Industries such as automotive, aerospace, construction, and heavy machinery rely heavily on precision cast carbon steel parts to maintain the integrity and functionality of their products.

Given the wide range of applications and the varying demands of different industries, it is crucial to select the right grade of carbon steel for casting. The choice of grade not only affects the performance and longevity of the cast part but also influences the efficiency of the casting process itself. Factors such as machinability, weldability, and the intended use of the final product must be carefully considered when choosing the appropriate carbon steel grade.

B. Importance of Choosing the Right Carbon Steel Grade for Custom Casting

Selecting the right grade of carbon steel for custom casting is paramount to achieving the desired balance of strength, durability, and cost-effectiveness. The grade of carbon steel used in casting directly impacts the physical and chemical properties of the final product. For example, the carbon content of the steel determines its hardness and tensile strength, while other alloying elements can influence factors like corrosion resistance and heat treatment capabilities.

When it comes to custom carbon steel casting, the stakes are particularly high because the components being produced are often designed to meet specific, rigorous standards. Whether it’s a critical automotive component that must endure high-stress conditions or a piece of industrial machinery that requires exceptional wear resistance, the success of the project hinges on selecting the appropriate steel grade. Failing to choose the right grade can lead to suboptimal performance, increased wear and tear, or even catastrophic failure in extreme cases.

Moreover, the choice of carbon steel grade affects the entire casting process, from the ease of molding and cooling to the post-casting treatments such as machining and welding. Different grades of carbon steel respond differently to heat and cooling rates, which can result in variations in the final product’s microstructure and mechanical properties. For instance, high carbon content might improve hardness but can also make the material more brittle, posing challenges during machining or if the part is subjected to impact loading.

Understanding the relationship between carbon steel grades and their suitability for specific applications is therefore essential. In the sections that follow, we will explore the different grades of carbon steel, their unique properties, and the factors that influence their selection for custom casting applications. This knowledge is vital for anyone involved in the procurement or production of precision cast carbon steel components, as it ensures that the end product meets the necessary specifications and performs reliably in its intended application.

II. Understanding Carbon Steel

A. What Is Carbon Steel?

Carbon steel is a type of steel where carbon is the primary alloying element. Unlike stainless steel or other alloy steels, carbon steel does not contain significant amounts of elements like chromium, nickel, or tungsten, which are added to achieve specific properties such as corrosion resistance or toughness. Instead, carbon steel is primarily composed of iron and carbon, with the carbon content typically ranging between 0.05% and 2.00%. This simple composition makes carbon steel a versatile and cost-effective material suitable for a wide range of industrial applications.

The properties of carbon steel are largely influenced by the amount of carbon present in the alloy. Higher carbon content generally increases hardness and strength but decreases ductility, making the steel more brittle. Conversely, lower carbon content results in a softer, more malleable steel that is easier to shape and weld but may lack the strength required for certain applications.

In custom carbon steel casting, the carbon content of the steel must be carefully controlled to achieve the desired balance of properties. This is because the carbon content not only affects the mechanical properties of the final cast product but also influences how the steel behaves during the casting process itself. For instance, higher carbon content can lead to increased hardness and wear resistance, which might be beneficial for some applications, but it can also make the steel more difficult to machine and more prone to cracking during cooling.

B. Categories of Carbon Steel

Carbon steel can be classified into four main categories based on its carbon content: low carbon steel (also known as mild steel), medium carbon steel, high carbon steel, and ultra-high carbon steel. Each category has distinct properties that make it suitable for different applications, and the choice of category often depends on the specific requirements of the casting process and the intended use of the final product.

Low Carbon Steel (Mild Steel)

Low carbon steel, or mild steel, contains carbon content ranging from 0.05% to 0.25%. This type of steel is characterized by its softness and ductility, making it easy to machine, weld, and form. Low carbon steel is widely used in custom casting because of its versatility and cost-effectiveness. It is often employed in the manufacturing of parts that do not require high strength or hardness, such as automotive body panels, structural beams, and various types of hardware.

Due to its low carbon content, mild steel has excellent weldability and can be easily manipulated during the casting process. However, it may require additional surface treatments, such as carburizing or nitriding, to enhance its hardness and wear resistance for certain applications. Despite its relatively low strength, mild steel remains a popular choice for many casting projects due to its affordability and ease of use.

Medium Carbon Steel

Medium carbon steel contains carbon content ranging from 0.25% to 0.60%. This category of steel offers a balance between strength and ductility, making it suitable for applications that require higher mechanical properties than mild steel can provide. Medium carbon steel is commonly used in the production of automotive parts, machinery components, and structural elements that require moderate strength and toughness.

The increased carbon content in medium carbon steel gives it greater hardness and strength compared to low carbon steel, but this also makes it less ductile and more challenging to weld. Custom casting with medium carbon steel often requires careful control of the cooling rate and post-casting heat treatments to achieve the desired properties and minimize the risk of cracking or distortion.

High Carbon Steel

High carbon steel contains carbon content ranging from 0.60% to 1.00%. This category of steel is known for its high strength and hardness, making it suitable for applications that demand exceptional wear resistance and durability. High carbon steel is commonly used in the manufacturing of cutting tools, springs, and high-strength wires.

Due to its high carbon content, this type of steel is much harder and more brittle than lower carbon steels. While this hardness is advantageous in certain applications, it also makes high carbon steel more difficult to work with during the casting process. Special care must be taken to control the cooling rate and avoid rapid quenching, which can lead to excessive brittleness and cracking. Additionally, high carbon steel typically requires heat treatment, such as tempering or annealing, to reduce brittleness and improve toughness.

Ultra-High Carbon Steel

Ultra-high carbon steel contains carbon content ranging from 1.00% to 2.00%. This type of steel is extremely hard and brittle, making it suitable for specialized applications where maximum wear resistance and strength are required. Ultra-high carbon steel is often used in the production of cutting tools, punches, and dies, where the material must withstand intense stress and maintain a sharp edge.

In custom casting, ultra-high carbon steel presents significant challenges due to its brittleness and tendency to crack during cooling. The casting process for ultra-high carbon steel typically requires very controlled conditions, including precise temperature management and post-casting heat treatments, to achieve the desired mechanical properties without compromising the integrity of the final product.

C. The Role of Carbon Content in Steel Properties

The carbon content of steel plays a crucial role in determining its mechanical properties, such as hardness, tensile strength, ductility, and toughness. As the carbon content increases, the steel becomes harder and stronger but also less ductile and more brittle. This trade-off between strength and ductility is a key consideration when selecting the appropriate grade of carbon steel for custom casting.

Impact on Hardness and Strength

Hardness and strength are directly related to the carbon content in steel. Higher carbon content leads to the formation of iron carbide (Fe3C), also known as cementite, which increases the hardness of the steel. This makes high carbon steels ideal for applications where wear resistance is critical, such as in cutting tools and abrasion-resistant components. However, this increased hardness also makes the steel more difficult to machine and more susceptible to cracking under stress.

Influence on Ductility and Toughness

Ductility and toughness are inversely related to the carbon content in steel. As carbon content increases, the steel becomes less ductile and more prone to brittleness. Low carbon steels, with their higher ductility, are better suited for applications where the material must undergo significant deformation without fracturing. This is why mild steel is commonly used in structural applications and in the production of components that require extensive forming or bending.

Effect on Weldability and Machinability

The carbon content of steel also affects its weldability and machinability. Low carbon steels are easier to weld and machine because they are softer and less prone to cracking during these processes. As the carbon content increases, the steel becomes harder and more difficult to work with. High carbon steels, in particular, may require preheating before welding and special tooling for machining to avoid issues such as cracking or tool wear.

Influence on Casting Outcomes

In custom carbon steel casting, the carbon content influences not only the final properties of the cast product but also the behavior of the steel during the casting process. Higher carbon content can lead to increased shrinkage and internal stresses during cooling, which may result in defects such as warping or cracking. The choice of carbon steel grade must therefore take into account not only the desired mechanical properties of the final product but also the specific requirements of the casting process to ensure a successful outcome.

III. Key Factors in Choosing Carbon Steel Grade for Custom Casting

A. Application-Specific Requirements

When choosing the right carbon steel grade for custom casting, the first consideration should be the specific requirements of the application. The intended use of the final product will dictate the necessary mechanical properties, such as tensile strength, hardness, impact resistance, and wear resistance. Different applications place different demands on the material, and the choice of carbon steel grade must align with these demands to ensure optimal performance.

Mechanical Properties

The mechanical properties required for the final product are crucial in determining the appropriate carbon steel grade. For example, if the cast part will be subjected to high levels of stress or impact, such as in automotive or heavy machinery applications, a medium to high carbon steel may be necessary to provide the required strength and toughness. On the other hand, if the part requires flexibility and must endure significant deformation, a low carbon steel with higher ductility may be more suitable.

Wear Resistance and Durability

For applications where wear resistance is a primary concern, such as in the manufacturing of cutting tools or abrasive components, high or ultra-high carbon steel is often preferred. These steels offer superior hardness and durability, making them capable of withstanding harsh operating conditions. However, the increased hardness of these steels comes with trade-offs in terms of machinability and weldability, which must be considered during the design and production stages.

Corrosion Resistance Needs

While carbon steel is generally not as corrosion-resistant as stainless steel, certain applications may still require some degree of corrosion protection. In such cases, surface treatments or coatings can be applied to the cast part to enhance its resistance to corrosion. Alternatively, alloying elements such as silicon or manganese may be added to the carbon steel to improve its resistance to oxidation and corrosion, depending on the specific environmental conditions the part will be exposed to.

B. Casting Method and Process Considerations

The method of casting and the specific process used can significantly influence the choice of carbon steel grade. Different casting methods, such as sand casting, investment casting, or die casting, have different requirements and limitations that must be taken into account when selecting the appropriate material.

Influence of Casting Method on Steel Grade Selection

Different casting methods have different cooling rates, mold materials, and processing conditions, all of which can affect the final properties of the cast steel. For example, sand casting is often used for larger parts with complex geometries, and it allows for slower cooling rates, which can help reduce the risk of cracking in high carbon steels. Investment casting, on the other hand, is ideal for producing smaller, more precise parts, but the faster cooling rates and finer mold materials may require lower carbon content to avoid issues such as internal stresses or distortion.

Cooling Rates and Their Impact on Steel Properties

The cooling rate during the casting process is a critical factor that affects the microstructure and mechanical properties of the final cast part. Faster cooling rates can lead to the formation of martensite in high carbon steels, resulting in increased hardness but also greater brittleness. Slower cooling rates allow for the formation of softer phases such as pearlite or ferrite, which can improve ductility but may reduce hardness. The choice of carbon steel grade must therefore consider the cooling rate of the casting method to achieve the desired balance of properties.

Mold Material Interaction with Carbon Steel Grades

The material of the mold used in casting can also influence the selection of carbon steel grade. For instance, certain mold materials may react with the carbon in the steel, leading to surface defects or unwanted chemical reactions. In such cases, the carbon content and other alloying elements in the steel must be carefully chosen to minimize these interactions and ensure a high-quality cast part.

C. Machinability and Weldability

After casting, many steel parts require further processing, such as machining or welding, to achieve the final dimensions and properties. The machinability and weldability of the carbon steel grade are therefore important considerations in the selection process.

Importance of Post-Casting Operations

Post-casting operations such as machining and welding are essential for producing parts with precise dimensions and complex shapes. The ease with which these operations can be performed depends on the carbon steel grade used. Lower carbon steels are generally easier to machine and weld due to their softer, more ductile nature. High carbon steels, while harder and more wear-resistant, may require specialized tooling and techniques to avoid issues such as tool wear or cracking during welding.

Machinability Considerations

Machinability refers to the ease with which a material can be cut, shaped, or drilled using conventional machining processes. Low carbon steels, such as mild steel, are highly machinable and can be easily shaped into complex geometries. Medium carbon steels offer a balance between machinability and strength, making them suitable for parts that require moderate mechanical properties. High carbon steels, due to their hardness, are more challenging to machine and may require special tooling, such as carbide-tipped tools, to achieve the desired results.

Weldability Considerations

Weldability is the ability of a material to be joined together through welding without compromising its structural integrity. Low carbon steels are highly weldable and do not typically require preheating or post-weld heat treatment. Medium and high carbon steels, on the other hand, may require preheating to reduce the risk of cracking and post-weld heat treatment to relieve internal stresses. The choice of carbon steel grade should take into account the specific welding requirements of the final product to ensure strong, defect-free welds.

D. Cost and Availability

Finally, the cost and availability of different carbon steel grades are important factors to consider when selecting a material for custom casting. While it is important to choose a steel grade that meets the technical requirements of the application, cost-effectiveness and material availability must also be taken into account to ensure the project remains economically viable.

Cost-Effectiveness of Different Carbon Steel Grades

Low carbon steels are generally the most cost-effective option due to their widespread availability and ease of processing. Medium and high carbon steels are more expensive due to their higher alloy content and the additional processing steps required to achieve the desired properties. Ultra-high carbon steels, while offering superior hardness and strength, are the most expensive and may only be justified for specialized applications where their unique properties are essential.

Material Availability in the Market

The availability of specific carbon steel grades can vary depending on the region and market demand. Some specialized grades may have longer lead times or be available only in limited quantities, which can impact the production schedule and overall cost of the project. It is important to work with reliable suppliers who can provide the required materials in a timely manner to avoid delays and ensure the success of the casting project.

IV. Common Grades of Carbon Steel Used in Custom Casting

A. Overview of Popular Carbon Steel Grades

In custom carbon steel casting, several grades of carbon steel are commonly used, each offering a unique balance of properties that make them suitable for specific applications. Some of the most popular grades include 1018, 1045, 1060, and 1095. These grades are well-known for their distinct chemical compositions and mechanical properties, which can be tailored to meet the specific needs of different industries.

B. Grade 1018

Grade 1018 is a low carbon steel with a carbon content of approximately 0.18%. It is widely used in custom casting due to its excellent machinability, weldability, and relatively low cost. 1018 steel offers good balance between strength and ductility, making it suitable for a wide range of applications, including automotive parts, machinery components, and structural elements.

Chemical Composition and Properties

The chemical composition of 1018 steel typically includes 0.15-0.20% carbon, 0.60-0.90% manganese, and trace amounts of phosphorus and sulfur. This composition gives 1018 steel a good combination of toughness, machinability, and ease of welding. The material is often used in the production of parts that require precision machining and can be case-hardened to improve surface hardness without affecting the core toughness.

Typical Applications and Advantages in Casting

1018 steel is commonly used in the casting of gears, shafts, spindles, and pins, where its good machinability and ductility are advantageous. It is also used in the manufacturing of parts that require cold forming or bending, as its low carbon content allows it to be easily shaped without cracking. Additionally, 1018 steel can be carburized to create a hard, wear-resistant surface, making it suitable for components that require both durability and machinability.

C. Grade 1045

Grade 1045 is a medium carbon steel with a carbon content of approximately 0.45%. It is known for its good balance of strength and toughness, making it a popular choice for custom casting in applications that require higher mechanical properties than 1018 steel can provide.

Chemical Composition and Properties

The chemical composition of 1045 steel typically includes 0.43-0.50% carbon, 0.60-0.90% manganese, and trace amounts of silicon, phosphorus, and sulfur. This composition gives 1045 steel increased strength and hardness compared to low carbon steels, while still maintaining good machinability and weldability. The material can be heat-treated to further enhance its mechanical properties, such as increasing its tensile strength and hardness.

Typical Applications and Advantages in Casting

1045 steel is commonly used in the casting of components such as axles, shafts, gears, and crankshafts, where its higher strength and toughness are beneficial. It is also used in the production of heavy machinery parts that require moderate wear resistance and durability. The material’s ability to be heat-treated makes it suitable for applications where the cast part must withstand higher levels of stress or impact.

D. Grade 1060

Grade 1060 is a high carbon steel with a carbon content of approximately 0.60%. It offers a higher level of strength and hardness compared to medium carbon steels, making it suitable for applications that require exceptional wear resistance and durability.

Chemical Composition and Properties

The chemical composition of 1060 steel typically includes 0.55-0.65% carbon, 0.60-0.90% manganese, and trace amounts of silicon, phosphorus, and sulfur. This composition gives 1060 steel high tensile strength and hardness, but also reduces its ductility and weldability. The material is often heat-treated to achieve specific properties, such as increased surface hardness for wear-resistant applications.

Typical Applications and Advantages in Casting

1060 steel is commonly used in the casting of cutting tools, springs, and wear-resistant components, where its high hardness and strength are advantageous. It is also used in the production of industrial machinery parts that require excellent durability and resistance to abrasion. The material’s ability to be heat-treated allows it to achieve the necessary hardness for demanding applications, making it a popular choice for custom casting in industries such as automotive, aerospace, and heavy equipment manufacturing.

E. Grade 1095

Grade 1095 is an ultra-high carbon steel with a carbon content of approximately 0.95%. It is known for its extreme hardness and strength, making it suitable for specialized applications that require maximum wear resistance and durability.

Chemical Composition and Properties

The chemical composition of 1095 steel typically includes 0.90-1.03% carbon, 0.30-0.50% manganese, and trace amounts of phosphorus and sulfur. This composition gives 1095 steel very high hardness and tensile strength, but also makes it extremely brittle and challenging to work with. The material is often used in applications where the cast part must maintain a sharp edge or withstand intense wear, such as in the production of cutting tools and dies.

Typical Applications and Advantages in Casting

1095 steel is commonly used in the casting of high-strength tools, knives, and other cutting implements, where its extreme hardness is essential. It is also used in the production of industrial machinery parts that require maximum wear resistance and durability. Due to its brittleness, 1095 steel is typically heat-treated to improve its toughness and reduce the risk of cracking during use.

F. Comparison of Grades

When selecting the appropriate carbon steel grade for custom casting, it is important to consider the specific requirements of the application and the trade-offs between different grades. For example, 1018 steel offers excellent machinability and weldability but may lack the strength and hardness required for certain applications. In contrast, 1095 steel offers maximum hardness and wear resistance but is more challenging to machine and weld.

The choice of grade should be based on the desired balance of properties, taking into account factors such as strength, hardness, ductility, machinability, and cost. By carefully selecting the appropriate carbon steel grade, manufacturers can ensure that the final cast part meets the necessary specifications and performs reliably in its intended application.

V. Case Studies: Choosing the Right Carbon Steel Grade for Specific Custom Casting Applications

A. Case Study 1: Automotive Industry

Requirements for Automotive Components

The automotive industry demands high-performance materials that can withstand significant stress, impact, and wear over the lifespan of a vehicle. Components such as gears, crankshafts, and axles must possess a combination of strength, toughness, and wear resistance to ensure reliable operation under various conditions. Additionally, these components often require precise dimensions and surface finishes, making machinability an important factor.

Selection of Carbon Steel Grade and Results

In this case study, a medium carbon steel such as Grade 1045 was chosen for the casting of automotive crankshafts. The higher carbon content provided the necessary strength and toughness to withstand the dynamic forces exerted on the crankshaft during engine operation. The material’s good machinability allowed for precise machining of the crankshaft’s bearing surfaces and journals, ensuring a smooth and reliable fit within the engine assembly.

The final cast product exhibited excellent durability and performance, withstanding the high-stress conditions typical of automotive applications. The use of Grade 1045 steel also allowed for cost-effective production while meeting the stringent quality standards required by the automotive industry.

B. Case Study 2: Industrial Machinery

Requirements for Heavy Machinery Components

Heavy machinery components, such as those used in construction and mining equipment, require materials with exceptional strength, toughness, and wear resistance. These components often operate under extreme conditions, including high loads, abrasive environments, and temperature fluctuations. The chosen material must be capable of withstanding these conditions without compromising the integrity or performance of the machinery.

Selection of Carbon Steel Grade and Results

For this case study, Grade 1060 steel was selected for the casting of wear-resistant components used in mining equipment. The high carbon content provided the necessary hardness and wear resistance to withstand the abrasive conditions encountered in mining operations. The material’s strength and toughness ensured that the components could endure the heavy loads and impact forces typical of this application.

The final cast parts demonstrated exceptional durability, significantly extending the service life of the machinery and reducing the frequency of maintenance and replacement. The use of Grade 1060 steel proved to be a cost-effective solution for producing high-performance components capable of withstanding the demanding conditions of the mining industry.

C. Case Study 3: Tool Manufacturing

Requirements for High-Strength Tools

In tool manufacturing, materials must possess high hardness and strength to maintain a sharp edge and withstand significant wear during use. Cutting tools, punches, and dies are often subjected to intense stress and abrasion, making material selection critical to ensuring long-lasting performance and reliability.

Selection of Carbon Steel Grade and Results

For this case study, Grade 1095 steel was chosen for the casting of cutting tools. The ultra-high carbon content provided the necessary hardness and wear resistance to maintain a sharp cutting edge over prolonged use. The material’s extreme hardness made it ideal for producing tools capable of cutting through tough materials without dulling or deforming.

The final cast tools exhibited superior performance, maintaining their sharpness and durability even after extended use in demanding applications. The use of Grade 1095 steel allowed for the production of high-quality tools that met the stringent requirements of the tool manufacturing industry, ensuring customer satisfaction and long-term reliability.

VI. Advantages and Challenges of Using Carbon Steel in Custom Casting

A. Advantages

Versatility in Casting

One of the primary advantages of using carbon steel in custom casting is its versatility. Carbon steel can be tailored to meet a wide range of mechanical properties by adjusting the carbon content and other alloying elements. This allows manufacturers to produce cast parts that are specifically designed to meet the unique requirements of different applications, from low-strength structural components to high-strength, wear-resistant tools.

Cost-Effectiveness

Carbon steel is a cost-effective material choice for custom casting due to its widespread availability and relatively low cost compared to other alloy steels. The ability to produce high-quality cast parts at a lower cost makes carbon steel an attractive option for industries that require large quantities of durable and reliable components. Additionally, the ease of machining and welding carbon steel further reduces production costs by minimizing the need for specialized equipment or processes.

Mechanical Strength and Wear Resistance

Carbon steel offers a good balance of mechanical strength and wear resistance, making it suitable for a wide range of applications. High carbon steels, in particular, provide excellent hardness and durability, making them ideal for producing wear-resistant components such as cutting tools, gears, and industrial machinery parts. The ability to heat-treat carbon steel to enhance its mechanical properties further increases its versatility and usefulness in custom casting.

B. Challenges

Potential Issues in Casting

Despite its advantages, carbon steel presents several challenges in the casting process. One of the main issues is the potential for warping, cracking, or porosity in the final cast product. These defects can result from improper cooling rates, uneven mold filling, or the presence of impurities in the steel. Careful control of the casting process, including temperature management and mold design, is essential to minimize these risks and ensure a high-quality cast part.

Handling High Carbon Content

High carbon content in steel can pose challenges during both the casting and post-casting processes. While high carbon content increases hardness and wear resistance, it also makes the material more brittle and difficult to machine or weld. Special techniques, such as preheating before welding or using carbide-tipped tools for machining, may be required to avoid cracking or excessive tool wear. Additionally, high carbon steels may require post-casting heat treatments, such as annealing or tempering, to relieve internal stresses and improve toughness.

Addressing the Need for Heat Treatment

Heat treatment is often necessary to achieve the desired mechanical properties in carbon steel castings, particularly for medium and high carbon steels. The heat treatment process can be complex and time-consuming, requiring precise control of temperature and cooling rates to avoid issues such as distortion or uneven hardness. The need for heat treatment adds an additional step to the production process, potentially increasing lead times and costs.

VII. Conclusion

A. Recap of Key Points

Selecting the right grade of carbon steel for custom casting is crucial to achieving the desired balance of strength, durability, and cost-effectiveness in the final product. The carbon content of the steel plays a significant role in determining its mechanical properties, such as hardness, tensile strength, ductility, and machinability. Understanding the relationship between carbon content and steel properties is essential for making informed decisions about material selection.

B. Final Recommendations

When choosing a carbon steel grade for custom casting, it is important to consider the specific requirements of the application, including the mechanical properties needed, the casting method used, and the post-casting operations required. By carefully selecting the appropriate grade of carbon steel, manufacturers can ensure that the final cast part meets the necessary specifications and performs reliably in its intended application.

Working with experienced suppliers and technical experts can help ensure that the right material is chosen and that the casting process is optimized to achieve the best possible results. Additionally, considering factors such as cost and availability can help ensure that the project remains economically viable while still meeting the necessary quality standards.

C. Call to Action

For businesses involved in precision casting, consulting with experts or requesting a quote for specific projects can help ensure that the right carbon steel grade is selected and that the final product meets the highest standards of quality and performance. Whether you are producing automotive components, industrial machinery parts, or high-strength tools, choosing the right carbon steel grade is the first step towards achieving success in your casting project.

Explore additional resources or services to learn more about custom carbon steel casting and how it can benefit your business. By partnering with experienced professionals, you can ensure that your cast parts are made to the highest standards, delivering the performance and reliability your customers expect.

IX. FAQs

A. What is the most common carbon steel grade used in casting?

Grade 1018 is one of the most commonly used carbon steel grades in casting due to its excellent machinability, weldability, and cost-effectiveness. It is widely used in automotive, machinery, and structural applications.

B. How does carbon content affect the casting process?

Carbon content plays a significant role in determining the mechanical properties of the cast steel. Higher carbon content increases hardness and strength but reduces ductility and weldability. The carbon content also affects the cooling rate and the risk of defects such as cracking or porosity during casting.

C. Can high carbon steel be used for casting?

Yes, high carbon steel can be used for casting, particularly for applications that require high hardness and wear resistance. However, high carbon steels are more brittle and challenging to work with, requiring careful control of the casting process and post-casting heat treatments.

D. What are the alternatives to carbon steel for casting?

Alternatives to carbon steel for casting include alloy steels, stainless steels, and ductile iron. Each material offers unique properties that may be more suitable for certain applications, depending on factors such as corrosion resistance, toughness, and cost.

E. How do you determine the best carbon steel grade for a specific casting project?

The best carbon steel grade for a specific casting project is determined by considering the application’s mechanical requirements, the casting method, post-casting operations, and cost constraints. Consulting with experts and reviewing the specific needs of the project will help ensure the right material is selected.