Aluminum rapid prototyping is transforming product design with quick and precise manufacturing. Manufacturers choose aluminum for its versatility and efficiency in producing prototypes that match real-world conditions, offering faster turnaround times.

Aluminum rapid prototyping utilizes advanced methods to create high-precision prototypes quickly. This allows for faster testing, iteration, and refinement of product designs, ultimately improving product development timelines.

Aluminum rapid prototyping offers key advantages in product development. By reducing production time and ensuring high precision, businesses can significantly cut costs and shorten their time-to-market. Keep reading to learn more about how aluminum rapid prototyping works and why it’s an ideal solution for your next product development project.

1. What is Aluminum Rapid Prototyping?

Aluminum rapid prototyping allows businesses to create high-quality prototypes quickly. But what exactly is it, and how does it work? Let’s break it down to help you understand how this method streamlines product development.

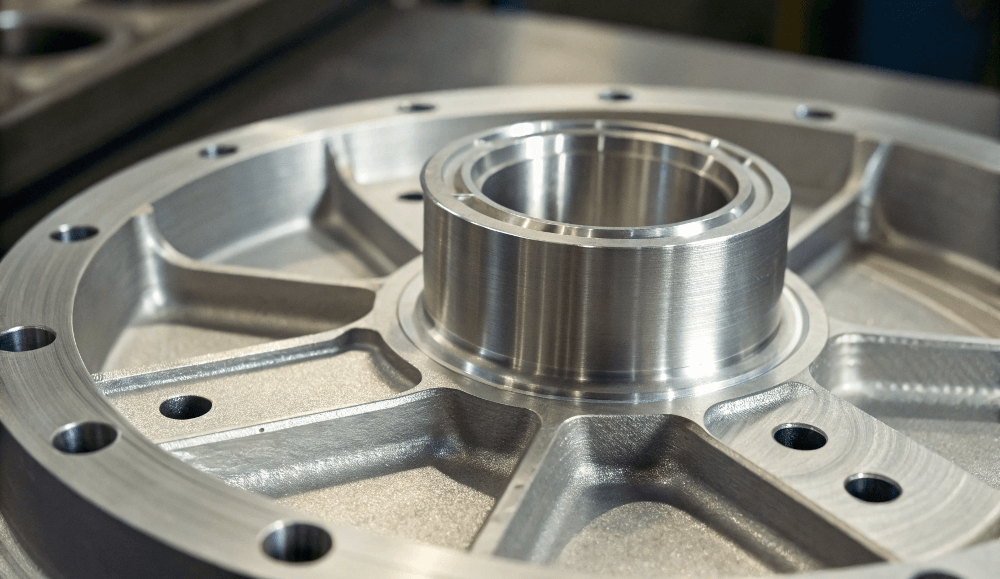

Aluminum is a lightweight, durable, and cost-effective material, which makes it a popular choice for rapid prototyping. The process involves using aluminum to create prototypes using advanced technologies like CNC machining or 3D printing. This allows businesses to quickly turn their ideas into tangible models, speeding up product development and reducing time-to-market.

The Process of Aluminum Rapid Prototyping Aluminum rapid prototyping typically starts with a 3D model or design. This model is then converted into a physical prototype using methods like CNC machining or additive manufacturing (3D printing). The result is a highly accurate and functional prototype made from aluminum that can be tested for fit, form, and function.

Aluminum is a preferred material because of its properties. It’s lightweight yet strong, offering high precision while being easy to machine. Unlike some other materials, aluminum can be easily shaped to meet the exact specifications of a design, making it ideal for prototypes that need to withstand real-world testing.

Key Features of Aluminum Prototypes:

| Feature | Description |

|---|---|

| Lightweight | Ideal for prototypes that require a low weight. |

| Strength | Offers high durability and resistance. |

| Machinability | Easy to shape and modify during prototyping. |

| Cost-Effectiveness | More affordable compared to many other metals. |

2. How Does Aluminum Rapid Prototyping Work?

Aluminum rapid prototyping works by turning digital 3D designs into physical prototypes through various manufacturing techniques. But what technologies are involved, and how do they contribute to the efficiency of the process?

At the heart of aluminum rapid prototyping are methods like CNC machining and 3D printing, each offering unique benefits in terms of speed and accuracy. CNC machining uses computer-controlled tools to shape aluminum into precise forms, while 3D printing builds objects layer by layer from a digital design.

Both methods allow for rapid prototyping of aluminum parts, enabling manufacturers to test and refine designs quickly. The beauty of rapid prototyping is that it allows companies to iterate on prototypes, improving the design without incurring costly and time-consuming delays associated with traditional manufacturing methods.

Advantages of CNC Machining and 3D Printing for Aluminum Prototyping CNC machining provides an extremely high level of precision, which is crucial when testing complex parts. On the other hand, 3D printing offers greater flexibility in design and allows for faster production of prototypes that don’t require as much fine-tuning.

| Method | Pros | Cons |

|---|---|---|

| CNC Machining | High precision, excellent for complex shapes. | Requires more setup time. |

| 3D Printing | Faster production, flexible design options. | Less precision for certain applications. |

3. Why Choose Aluminum for Prototyping?

Why is aluminum such a popular choice for prototyping? It has a range of characteristics that make it an ideal material for creating accurate and durable prototypes.

Aluminum offers a combination of lightness and strength, making it suitable for testing in real-world conditions. Whether you are developing prototypes for the automotive, aerospace, or electronics industries, aluminum ensures that the final product can withstand harsh conditions while remaining lightweight and easy to handle.

Aluminum vs Other Materials Aluminum’s strength-to-weight ratio is superior to many other materials, like plastics and steel, which is why it is often preferred in industries where weight and durability matter. Moreover, aluminum is highly machinable, meaning it can be shaped to meet exact design requirements, which is crucial in prototyping.

Why Aluminum Is Ideal:

| Material Property | Aluminum | Other Materials |

|---|---|---|

| Weight | Lightweight for easy handling and transport. | Steel is heavier; plastics may be too fragile. |

| Strength | Strong enough for real-world testing. | Plastics can’t match aluminum’s strength. |

| Cost | Cost-effective for rapid prototyping. | Steel may be more expensive. |

4. What Are the Main Applications of Aluminum Prototyping?

Aluminum rapid prototyping has a variety of applications in different industries. But which industries benefit most from using aluminum prototypes?

Aluminum is widely used in industries where strength, durability, and precision are critical. For example, in the automotive industry, aluminum prototypes help manufacturers test parts for performance and fit before mass production. In aerospace, aluminum prototypes are used to test components for weight and strength before final assembly. The flexibility and high precision of aluminum make it an ideal choice for industries like electronics and medical devices as well.

Key Applications:

- Automotive Industry: Test parts like engine components, chassis, and structural elements.

- Aerospace: Prototype flight-critical components such as wings, landing gear, and fuselage parts.

- Electronics: Develop heat sinks and other parts for electronic devices.

- Medical Devices: Create durable, precise components for medical equipment.

| Industry | Common Applications | Key Benefits of Aluminum |

|---|---|---|

| Automotive | Engine parts, chassis, body components | Lightweight, strong, durable. |

| Aerospace | Airframe parts, landing gear, propulsion systems | High strength-to-weight ratio. |

| Electronics | Heat sinks, enclosures, connectors | Excellent heat conductivity, durability. |

5. How Does Aluminum Rapid Prototyping Compare to Other Materials?

When choosing a material for rapid prototyping, aluminum stands out for its unique properties. But how does it compare to other materials such as plastics and steel?

Aluminum offers a better combination of strength and weight compared to plastics, making it ideal for testing components that need to withstand real-world conditions. Plastics, while cheaper and lighter, often lack the strength required for applications like automotive or aerospace prototypes. On the other hand, steel is stronger than aluminum, but it’s heavier and more expensive, which can increase production costs and time for prototyping.

Comparing Aluminum to Plastics and Steel:

| Property | Aluminum | Plastics | Steel |

|---|---|---|---|

| Weight | Lightweight and easy to handle. | Lighter but often lacks strength. | Heavier, not ideal for weight-sensitive designs. |

| Strength | Strong and durable, suitable for many applications. | Not as strong as aluminum or steel. | Stronger than aluminum but not as light. |

| Cost | Cost-effective for rapid prototyping. | Typically cheaper than aluminum. | Higher cost due to material and machining expenses. |

| Machinability | Easy to machine, can achieve high precision. | Can be molded but less precise. | Difficult to machine, requires complex processes. |

6. What Are the Key Advantages of Aluminum Rapid Prototyping?

Aluminum rapid prototyping offers several advantages, making it a go-to choice for many industries. The process is faster, more precise, and cost-effective, allowing for quick validation of design ideas.

The speed of aluminum prototyping allows businesses to test and iterate designs quickly, reducing overall time-to-market. Since aluminum is easy to machine and works well with a variety of prototyping technologies, companies can quickly identify and resolve potential design flaws before full-scale production. Moreover, the durability of aluminum ensures that prototypes can be tested under real-world conditions.

Key Advantages:

| Advantage | Description |

|---|---|

| Speed | Rapid production allows for quick testing and iteration. |

| Precision | High accuracy and fine details are achievable, making it ideal for complex prototypes. |

| Cost-Effectiveness | More affordable than traditional manufacturing methods, especially for small production runs. |

| Durability | Aluminum’s strength ensures prototypes can withstand real-world tests. |

7. How Can Aluminum Rapid Prototyping Improve Your Product Development?

Aluminum rapid prototyping can streamline your product development process. But how exactly does it improve the overall development cycle?

By enabling rapid testing and refinement, aluminum prototypes allow for more iterations in a shorter period of time. This iterative process helps businesses identify design flaws early, making it easier to fix issues before moving to full-scale production. The increased testing and validation mean that the final product is more likely to meet performance and quality expectations, reducing the risk of costly mistakes later.

How It Works:

| Benefit | Description |

|---|---|

| Faster Time-to-Market | By shortening the design and testing phases, prototypes can be validated and adjusted faster. |

| Cost Savings | Early detection of design flaws reduces the need for costly modifications in later stages. |

| Improved Design Accuracy | Iterative prototyping ensures the final product is more accurate and functional. |

8. What Are the Common Challenges with Aluminum Prototyping?

While aluminum rapid prototyping offers many advantages, it does come with its challenges. Understanding these challenges helps businesses prepare for any potential issues that may arise during the prototyping phase.

One of the main challenges with aluminum prototyping is achieving perfect surface finishes. Aluminum is prone to slight imperfections, which can affect the appearance and functionality of the prototype. Additionally, machining aluminum requires specialized equipment and skills, which can add complexity and cost. Despite these challenges, the benefits of using aluminum typically outweigh the drawbacks, especially when precise, durable prototypes are needed.

Common Challenges:

| Challenge | Description |

|---|---|

| Surface Finish Issues | Achieving a smooth, perfect finish can be difficult and may require additional processing. |

| Machining Complexity | Specialized equipment is needed for precise machining, which can increase costs. |

| Material Defects | Aluminum may experience slight defects like cracks or imperfections during production. |

9. How Do You Choose the Right Prototyping Service for Aluminum Projects?

Choosing the right prototyping service is critical for ensuring the success of your aluminum rapid prototyping project. But how can you select a service that meets your specific needs?

When selecting a prototyping service, it’s important to consider factors such as their experience with aluminum, the technologies they use, and their ability to meet deadlines. Look for companies with a proven track record in delivering high-quality aluminum prototypes and the necessary machinery for precision. Additionally, consider their customer service and support throughout the prototyping process, as clear communication is key to the success of your project.

Selecting the Right Service:

| Factor | Consideration |

|---|---|

| Experience | Choose a service with a solid history of working with aluminum and similar projects. |

| Technology | Ensure the service uses advanced technologies like CNC machining and 3D printing. |

| Communication | Reliable communication is crucial for keeping the project on track and addressing issues quickly. |

| Turnaround Time | Look for a service that can meet your deadlines without sacrificing quality. |

10. What Industries Benefit Most from Aluminum Rapid Prototyping?

Aluminum rapid prototyping serves a broad range of industries, each with unique requirements. But which industries see the most significant benefits from using aluminum in their prototyping processes?

Industries that rely on high precision, strength, and lightweight materials are the main users of aluminum rapid prototyping. For instance, the automotive industry uses aluminum prototypes to test and refine vehicle components, ensuring they can withstand harsh conditions while maintaining weight efficiency. In aerospace, aluminum prototypes are essential for testing flight components, where both weight and durability are critical. The medical and electronics industries also benefit from aluminum’s ability to provide durable prototypes with excellent heat conductivity.

Industries Using Aluminum Prototyping:

| Industry | Key Applications | Benefits of Aluminum |

|---|---|---|

| Automotive | Engine parts, chassis, structural elements | Lightweight, durable, cost-effective |

| Aerospace | Airframe parts, landing gear, engine components | High strength-to-weight ratio, durability |

| Medical Devices | Surgical tools, implants, diagnostic equipment | Biocompatible, precision, durability |

| Electronics | Heat sinks, enclosures, connectors | Excellent heat conductivity, lightweight |

| Consumer Goods | Household products, appliances | Cost-efficient, versatile, durable |

11. How Does Aluminum Prototyping Impact the Manufacturing Process?

Aluminum rapid prototyping plays a significant role in bridging the gap between design and mass production. But how exactly does it impact the larger manufacturing process?

One key way aluminum prototyping affects manufacturing is by enabling design testing before production. By creating accurate prototypes, companies can evaluate the performance and functionality of components early on, which reduces the risk of costly errors during mass production. Furthermore, aluminum prototypes are tested under real-world conditions, which helps improve the reliability of the final product. This early-stage evaluation also allows for refining the design to match production standards.

Impact of Aluminum Prototyping:

| Impact | Description |

|---|---|

| Early Design Testing | Prototypes are tested to ensure functionality before mass production. |

| Improved Accuracy | Prototypes provide a high level of precision, reducing the chance of errors in manufacturing. |

| Reduced Errors | Testing aluminum prototypes early in the process minimizes costly mistakes in later stages. |

12. What Are the Environmental Benefits of Aluminum Rapid Prototyping?

Environmental sustainability is increasingly important in product development. But how does aluminum rapid prototyping contribute to a more eco-friendly manufacturing process?

Aluminum is one of the most sustainable materials available. It’s highly recyclable, making it an ideal choice for environmentally conscious prototyping. Using aluminum in rapid prototyping reduces waste because only the necessary amount of material is used during production. Additionally, aluminum’s long lifespan means that products made from aluminum are more durable and have a lower environmental impact over time compared to other materials that may need to be replaced more frequently.

Environmental Benefits of Aluminum:

| Benefit | Description |

|---|---|

| Recyclability | Aluminum can be recycled repeatedly without losing quality. |

| Low Waste | Rapid prototyping methods minimize material waste compared to traditional methods. |

| Durability | Aluminum products tend to last longer, reducing the need for replacements. |

13. What Are the Cost Considerations for Aluminum Prototyping?

Cost is always a consideration in manufacturing. But what are the specific costs associated with aluminum rapid prototyping, and how can they be managed?

Aluminum rapid prototyping is often more affordable than traditional manufacturing methods, especially for low-volume production. The initial cost of creating a prototype is relatively low compared to the cost of producing parts in bulk using other materials like steel. However, the cost can increase depending on the complexity of the design, the techniques used (such as CNC machining vs. 3D printing), and the level of precision required. To manage costs effectively, it’s essential to select the right prototyping service and ensure that the design is optimized for rapid prototyping processes.

Cost Breakdown:

| Factor | Description |

|---|---|

| Material Cost | Aluminum is affordable compared to metals like steel. |

| Production Cost | CNC machining or 3D printing costs depend on design complexity and part size. |

| Design Optimization | Efficient designs can reduce prototyping costs and lead to savings in production. |

14. What Are the Future Trends in Aluminum Rapid Prototyping?

Aluminum rapid prototyping is evolving with technological advancements. But what trends can we expect to see in the future of aluminum prototyping?

Technological innovations are continually improving the speed and precision of aluminum rapid prototyping. For instance, advancements in 3D printing technology allow for even faster production times and more intricate designs. Additionally, new materials and alloys are being developed to enhance aluminum’s properties, offering greater strength and resistance to environmental factors. As these technologies advance, the potential for aluminum rapid prototyping to revolutionize industries like aerospace, automotive, and medical devices continues to grow.

Future Trends:

| Trend | Description |

|---|---|

| Advanced 3D Printing | Faster and more precise printing methods will continue to evolve. |

| New Aluminum Alloys | Development of stronger, more durable aluminum alloys will improve performance. |

| Automation in Prototyping | More automated systems will streamline the prototyping process, reducing costs and time. |

15. How Can You Ensure the Success of Your Aluminum Prototyping Project?

Aluminum rapid prototyping can be highly beneficial, but success depends on how you approach the process. How can you ensure that your project is successful from start to finish?

The key to success is working with an experienced prototyping service, having a clear design plan, and maintaining constant communication throughout the process. Select a prototyping service that specializes in aluminum and has a track record of delivering quality prototypes on time. Be sure to refine your design to suit the prototyping process, reducing unnecessary complexity. Finally, ensure that all testing is done thoroughly to validate the prototype before moving to mass production.

Key Success Factors:

| Factor | Description |

|---|---|

| Experience | Choose a service with experience in aluminum prototyping and relevant industries. |

| Clear Design | Have a well-defined design that is optimized for prototyping. |

| Communication | Maintain regular communication with the prototyping service to ensure smooth execution. |

| Testing | Thoroughly test prototypes to ensure they meet functional and design specifications. |

Conclusion

Aluminum rapid prototyping offers businesses a fast, efficient way to create high-quality prototypes for testing and development. By choosing aluminum, companies gain access to a material that combines strength, precision, and cost-effectiveness, ensuring that prototypes meet the required specifications before moving into mass production. Whether in automotive, aerospace, or other industries, aluminum rapid prototyping is key to reducing time-to-market and improving product quality.

FAQ

Q1: What is aluminum rapid prototyping?

Aluminum rapid prototyping is a process of creating prototypes from aluminum using advanced techniques like CNC machining or 3D printing. This method allows for fast, accurate creation of prototypes for various industries.

Q2: How does aluminum rapid prototyping work?

The process involves taking a 3D design and using technologies like CNC machining or 3D printing to create a physical prototype. This allows for quick testing and refinement of the design.

Q3: Why is aluminum used for prototyping?

Aluminum is lightweight yet strong, making it ideal for testing prototypes in real-world conditions. It’s also highly machinable, allowing for precise, durable prototypes at a reasonable cost.

Q4: What are the main benefits of aluminum rapid prototyping?

The main benefits include faster production times, cost efficiency, and high precision. Aluminum allows for accurate, real-world testing of prototypes, reducing the risk of failure in the final product.

Q5: How do I choose the right aluminum prototyping service?

Look for a service that specializes in aluminum, has experience with the specific technology you need (CNC or 3D printing), and provides reliable customer service and fast turnaround times.