Stainless steel investment casting is a crucial process used in industries such as aerospace, automotive, and medical devices. The complexity of manufacturing precision parts requires a deep understanding of casting techniques.

Stainless steel investment casting involves creating complex metal parts through a precision process, offering strength, accuracy, and durability. This method is essential for industries that demand high-performance components.

Many professionals still face challenges when selecting the right process for their products. Let’s explore the process of stainless steel investment casting in detail.

1. What is Stainless Steel Investment Casting?

Stainless steel investment casting is widely recognized for its precision in creating high-quality components. Investment casting, also known as lost-wax casting, allows manufacturers to make complex parts with exact measurements and fine details.

How does stainless steel investment casting work?

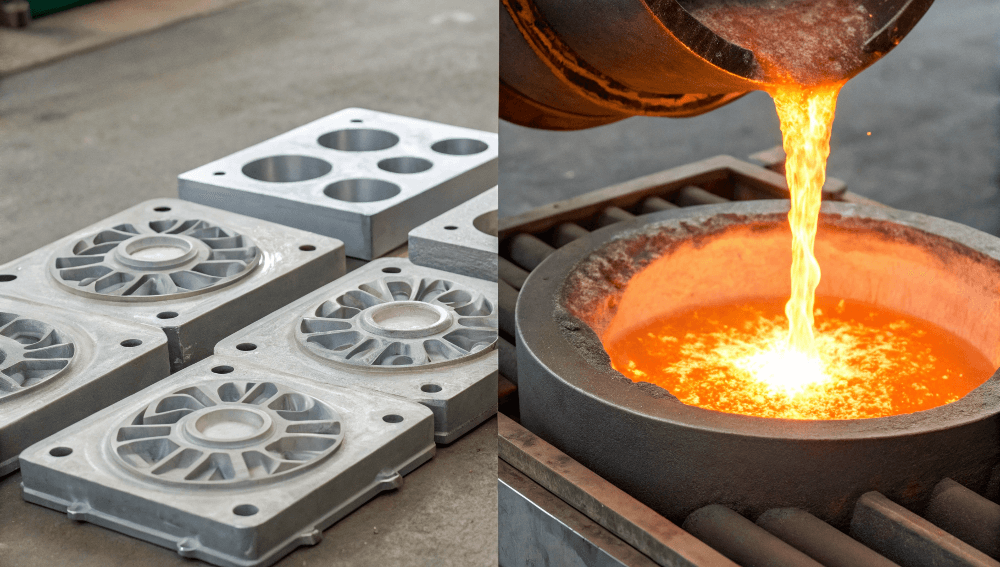

Investment casting begins with a pattern made of wax or another material. This pattern is coated with a ceramic shell, and once the shell hardens, the wax is melted away. The remaining mold is filled with molten stainless steel, and once it cools, the final part is removed and finished.

Process Steps in Stainless Steel Investment Casting

| Step | Description |

|---|---|

| Pattern | Create a model of the component, typically using wax or another material. |

| Shelling | Coat the pattern with a ceramic shell for mold creation. |

| Dewaxing | Heat the shell to melt the wax, leaving behind an empty mold. |

| Pouring | Pour molten stainless steel into the mold to form the part. |

| Cooling | Let the cast material cool and solidify before removal from the mold. |

| Finishing | Perform finishing steps, such as grinding, polishing, or machining. |

Investment casting is used for producing parts with intricate shapes and tight tolerances, making it perfect for industries like aerospace, automotive, and medical devices. The flexibility of this process allows manufacturers to produce high-performance components tailored to specific needs.

2. How Does Stainless Steel Investment Casting Work?

The stainless steel investment casting process starts with creating a pattern, often from wax. The pattern is then coated in a ceramic shell that is heat-resistant. Once the shell hardens, the pattern is melted out, and molten stainless steel is poured into the mold. After cooling, the mold is broken, revealing the cast part.

Why is stainless steel investment casting preferred in manufacturing?

Stainless steel is chosen for its durability, resistance to corrosion, and high strength. These qualities make stainless steel investment casting the ideal choice for creating components that need to withstand harsh environments, high temperatures, or mechanical stress.

Advantages of Stainless Steel Investment Casting

| Advantage | Description |

|---|---|

| High Precision | Investment casting ensures parts are made to exact specifications. |

| Complex Geometries | Able to create parts with intricate shapes, ideal for customized designs. |

| Strength and Durability | Stainless steel’s inherent properties enhance the overall strength and lifespan. |

| Cost-Effective for Small Batches | Particularly efficient when producing small quantities of parts. |

Stainless steel investment casting is ideal for creating custom, high-performance parts used in demanding applications. By ensuring precision and durability, this casting method continues to be an essential manufacturing process.

3. Why is Stainless Steel Investment Casting Important?

In sectors such as aerospace and automotive, where precision is critical, stainless steel investment casting provides the required accuracy and reliability for components that must endure extreme conditions.

How does investment casting benefit industries?

Investment casting allows manufacturers to produce parts that are lightweight yet strong, capable of handling intense pressures and temperatures. This versatility ensures that industries can produce reliable components for various applications.

Impact on Industries

| Industry | Impact of Stainless Steel Investment Casting |

|---|---|

| Aerospace | Produces parts that withstand extreme temperatures and pressures, ensuring safety and reliability. |

| Automotive | Components like engine parts that require strength and precision in complex geometries. |

| Medical Devices | Critical for surgical instruments, implants, and devices needing high reliability. |

Investment casting is indispensable in the manufacturing of parts that require high strength, accuracy, and complex geometry. Its importance in these industries cannot be overstated, as it guarantees superior quality and performance.

4. What Are the Benefits of Stainless Steel Investment Casting?

Investment casting offers several key benefits, including superior surface finish, dimensional accuracy, and the ability to cast complex shapes without the need for additional machining.

What makes stainless steel investment casting unique?

Unlike other methods like sand casting, stainless steel investment casting is capable of producing near-net shape components that require minimal post-processing. This reduces production time and costs while maintaining part quality.

Benefits in Detail

| Benefit | Description |

|---|---|

| High Dimensional Accuracy | Investment casting ensures minimal tolerance levels, improving fit and function. |

| Reduced Waste | As a near-net shape process, it reduces material waste, making it more sustainable. |

| Customizability | Offers greater flexibility for producing unique, complex designs. |

The benefits of stainless steel investment casting are clear, making it an ideal choice for high-precision, low-waste manufacturing of complex components.

5. What Types of Stainless Steel Are Used in Investment Casting?

Various grades of stainless steel are used in investment casting, depending on the specific application and desired properties of the final product.

What are the common types of stainless steel used?

Austenitic, ferritic, and martensitic stainless steels are commonly used in investment casting. Each offers unique benefits, such as enhanced corrosion resistance or the ability to withstand high temperatures.

Stainless Steel Types and Their Uses

| Type | Properties | Common Uses |

|---|---|---|

| Austenitic | Excellent corrosion resistance, formability, and weldability. | Automotive, medical devices, chemical industries. |

| Ferritic | Good resistance to stress corrosion cracking, lower cost. | Automotive exhausts, industrial applications. |

| Martensitic | High hardness, wear resistance, and strength. | Aerospace, industrial equipment, turbine blades. |

Choosing the right type of stainless steel for investment casting is critical to ensuring the part meets performance requirements.

6. What Are the Key Applications of Stainless Steel Investment Casting?

Stainless steel investment casting is widely used across various industries. The precision and versatility of the process make it ideal for producing components used in demanding environments.

What are the key industries benefiting from stainless steel investment casting?

The aerospace, automotive, medical, and industrial sectors all heavily rely on investment casting to create parts that must endure high temperatures, pressure, and wear.

Applications of Stainless Steel Investment Casting

| Industry | Key Applications |

|---|---|

| Aerospace | Aircraft engine components, landing gear parts, and other precision parts. |

| Automotive | Engine parts, transmission components, and brake systems. |

| Medical Devices | Surgical tools, implants, and diagnostic equipment. |

| Industrial Machinery | Pump parts, valve components, and machinery for harsh environments. |

Stainless steel investment casting enables the creation of critical components for these industries, improving their performance and reliability.

7. What Are the Challenges of Stainless Steel Investment Casting?

While stainless steel investment casting offers numerous benefits, it also comes with a set of challenges that manufacturers must address. These include the complexities of the casting process, material costs, and maintaining consistent quality.

What challenges do manufacturers face with stainless steel investment casting?

Investment casting is a highly precise process, but issues such as mold defects, material inconsistencies, and the high cost of materials can complicate production. These challenges require strict quality control measures and advanced manufacturing techniques to overcome.

Common Challenges in Stainless Steel Investment Casting

| Challenge | Description |

|---|---|

| Mold Integrity | Molds can be prone to cracks or defects, affecting the final product’s quality. |

| Material Cost | High-quality stainless steel can be expensive, increasing production costs. |

| Consistent Quality | Maintaining consistent casting quality across large batches can be difficult. |

| Post-Processing Needs | Some parts may require additional machining or surface treatment. |

Addressing these challenges requires investment in advanced technologies, skilled labor, and comprehensive quality assurance processes. By tackling these issues head-on, manufacturers can ensure they meet industry standards and customer expectations.

8. How Do You Select a Stainless Steel Investment Casting Supplier?

Choosing the right supplier for stainless steel investment casting is crucial for ensuring the production of high-quality parts that meet your specifications. Factors such as experience, reliability, and certifications should be considered when evaluating potential suppliers.

What makes a good stainless steel investment casting supplier?

A reputable supplier should have a proven track record of delivering high-quality parts, maintaining strict quality control processes, and being able to meet tight deadlines. Furthermore, they should offer transparent communication and provide clear responses to technical inquiries.

Key Factors to Consider When Selecting a Supplier

| Factor | Consideration |

|---|---|

| Experience | Ensure the supplier has significant experience in the investment casting industry. |

| Certifications | Check for relevant industry certifications (ISO, ASTM, etc.). |

| Quality Control | Look for robust quality assurance processes that ensure consistent product quality. |

| Delivery Timelines | Verify the supplier’s ability to meet your production and delivery schedules. |

Choosing the right supplier can make or break a project. It’s essential to evaluate potential partners carefully to avoid production delays and ensure the highest quality parts.

9. What Are the Differences Between Stainless Steel Investment Casting and Other Casting Methods?

Stainless steel investment casting is just one of many casting methods available. Understanding the differences between this method and others, like sand casting or die casting, is essential for choosing the right technique for your specific needs.

How does investment casting compare to other methods?

Unlike sand casting, which is suitable for larger parts with less detail, investment casting allows for precise dimensions and smooth finishes. It’s also more effective for producing small quantities of complex components, whereas die casting is ideal for high-volume production of smaller parts.

Comparison of Casting Methods

| Casting Method | Key Characteristics | Best Suited For |

|---|---|---|

| Investment Casting | High precision, complex geometries, excellent surface finish | Small to medium parts with intricate details |

| Sand Casting | Lower precision, rougher surfaces, higher material waste | Large, simple parts |

| Die Casting | High production speed, excellent for small, complex parts with high volumes | Mass production of small parts |

| Permanent Mold Casting | Uses a reusable mold, faster cycle times than sand casting | Medium-volume production of smaller parts |

Understanding the strengths and weaknesses of each method ensures that you select the best one for your project’s specific requirements.

10. How is Quality Control Managed in Stainless Steel Investment Casting?

Quality control is crucial in stainless steel investment casting to ensure that the finished parts meet the desired specifications and are free of defects. Manufacturers implement a variety of testing and inspection techniques to guarantee the final product’s performance.

What quality control measures are taken in stainless steel investment casting?

Quality control involves several stages, including visual inspections, non-destructive testing, and dimensional checks. These measures help identify defects early in the process, minimizing the need for costly rework and ensuring that parts meet industry standards.

Key Quality Control Techniques

| Technique | Purpose |

|---|---|

| Visual Inspection | To detect surface defects, cracks, and imperfections. |

| Dimensional Checking | To ensure the part conforms to specified measurements and tolerances. |

| X-ray or Ultrasonic Testing | To detect internal flaws or voids that may not be visible on the surface. |

| Hardness Testing | To ensure the part meets the required mechanical properties and durability. |

By implementing comprehensive quality control measures, manufacturers can produce parts that are reliable, consistent, and capable of performing in demanding applications.

11. What Are the Environmental Impacts of Stainless Steel Investment Casting?

As industries become more focused on sustainability, it’s important to consider the environmental impact of manufacturing processes. Stainless steel investment casting has both environmental challenges and opportunities for improvement.

What environmental considerations should be made in investment casting?

The casting process can produce waste materials, such as ceramic shells, wax patterns, and used sand, which need to be managed responsibly. Additionally, energy consumption during the melting process can contribute to a higher environmental footprint.

Environmental Impact Considerations

| Consideration | Impact |

|---|---|

| Waste Management | Recycling and reusing materials like wax and ceramic shells to reduce waste. |

| Energy Use | High energy consumption for melting metal; switching to greener technologies can help. |

| Emissions | Reducing CO2 emissions through cleaner manufacturing practices and equipment. |

With the right technologies and waste management practices, the environmental impact of stainless steel investment casting can be minimized, making it a more sustainable manufacturing option.

12. How Can the Cost of Stainless Steel Investment Casting Be Reduced?

While investment casting is efficient, it can be an expensive process due to the cost of raw materials, labor, and equipment. However, there are ways to optimize the process and reduce costs without compromising on quality.

What strategies can be used to reduce investment casting costs?

Investing in automation and improving process efficiency can significantly lower production costs. Additionally, optimizing the design of parts to minimize material waste can help keep costs down.

Strategies for Cost Reduction

| Strategy | Benefit |

|---|---|

| Automation | Reduces labor costs and increases production efficiency. |

| Material Optimization | Reduces scrap and waste by refining the design and material usage. |

| Economies of Scale | Produces parts in larger quantities to reduce per-unit costs. |

By focusing on process optimization and utilizing advanced technologies, manufacturers can lower costs while maintaining the high-quality standards expected from stainless steel investment casting.

13. What Are the Latest Trends in Stainless Steel Investment Casting?

Innovation continues to drive advancements in stainless steel investment casting, from new materials to advanced manufacturing techniques. Staying ahead of these trends is essential for manufacturers looking to remain competitive.

What are some of the emerging trends in stainless steel investment casting?

3D printing and automation are two of the most significant trends in the industry. These technologies allow for faster, more precise manufacturing with less material waste, leading to greater efficiency and cost savings.

Key Trends Shaping the Future of Investment Casting

| Trend | Impact |

|---|---|

| 3D Printing | Enables more complex designs and faster prototyping. |

| Automation | Increases efficiency, reduces labor costs, and ensures consistency. |

| Sustainable Practices | Focus on reducing energy use and minimizing material waste. |

By embracing these trends, manufacturers can enhance their capabilities, produce better-quality parts, and stay competitive in the global market.

14. What Is the Future of Stainless Steel Investment Casting?

As industries demand higher performance and greater customization, stainless steel investment casting will continue to evolve. New materials and technologies will make casting even more efficient and cost-effective.

What does the future hold for stainless steel investment casting?

The integration of AI, automation, and advanced 3D printing will further improve precision and reduce production times. Additionally, the focus on sustainability will drive the development of more eco-friendly casting processes.

Future Developments in Stainless Steel Investment Casting

| Development | Impact |

|---|---|

| Artificial Intelligence | Enhances quality control and design precision, reduces human error. |

| Advanced 3D Printing | Allows for more complex designs and faster turnarounds. |

| Eco-friendly Materials | Reduces the environmental impact of casting processes. |

The future of stainless steel investment casting looks bright, with continuous advancements driving improvements in quality, efficiency, and sustainability.

15. How Can You Get Started with Stainless Steel Investment Casting?

For companies looking to begin utilizing stainless steel investment casting, it’s important to understand the process, choose the right supplier, and optimize production techniques to meet specific requirements.

How can a business start using stainless steel investment casting?

The first step is to assess your product’s design and material requirements, followed by selecting a reputable casting supplier. It’s also essential to review the entire production process to ensure it aligns with your cost and quality expectations.

Steps to Get Started

| Step | Description |

|---|---|

| Design Assessment | Analyze the product’s design to ensure it is suited for investment casting. |

| Supplier Selection | Choose a supplier with a proven track record and expertise in investment casting. |

| Process Optimization | Streamline the process to maximize efficiency and reduce costs. |

By following these steps, businesses can successfully implement stainless steel investment casting in their production process, ensuring high-quality components and a smooth manufacturing experience.

Conclusion

Stainless steel investment casting offers an ideal solution for producing high-precision, durable parts used across various industries. Its ability to create complex shapes and provide reliable components makes it a valuable process for manufacturing. As industries continue to demand parts with greater strength and performance, stainless steel investment casting remains a top choice.

FAQ Section

- Q1: What is stainless steel investment casting?

Stainless steel investment casting is a manufacturing process where a pattern is created, coated with a ceramic shell, and filled with molten stainless steel to create precise parts used in industries like aerospace, automotive, and medical. - Q2: How does stainless steel investment casting work?

The process begins with a wax pattern, which is coated in a ceramic shell. Once the pattern is melted out, molten stainless steel is poured into the mold, and the part is finished through cooling and post-processing steps. - Q3: What are the benefits of stainless steel investment casting?

Investment casting offers high precision, minimal waste, and the ability to create complex geometries, making it ideal for industries requiring durable and high-performance parts. - Q4: What types of stainless steel are used in investment casting?

Austenitic, ferritic, and martensitic stainless steels are commonly used in investment casting, each providing unique properties such as corrosion resistance, strength, and formability. - Q5: How can I choose the best stainless steel investment casting supplier?

Look for a supplier with extensive experience, certifications, and the ability to meet your specific part requirements. Quality control, production capacity, and delivery timelines are key considerations.