When selecting between stainless steel and aluminum castings, many factors should be considered. Whether it’s durability, cost, or weight, understanding the differences can help you choose the right material for your project.

Both stainless steel and aluminum have unique properties, making them suitable for specific applications. Knowing when to use each material can lead to cost savings and improved performance for your products.

Now that we’ve set the stage, let’s dive into the comparison of stainless steel and aluminum castings and explore their respective benefits.

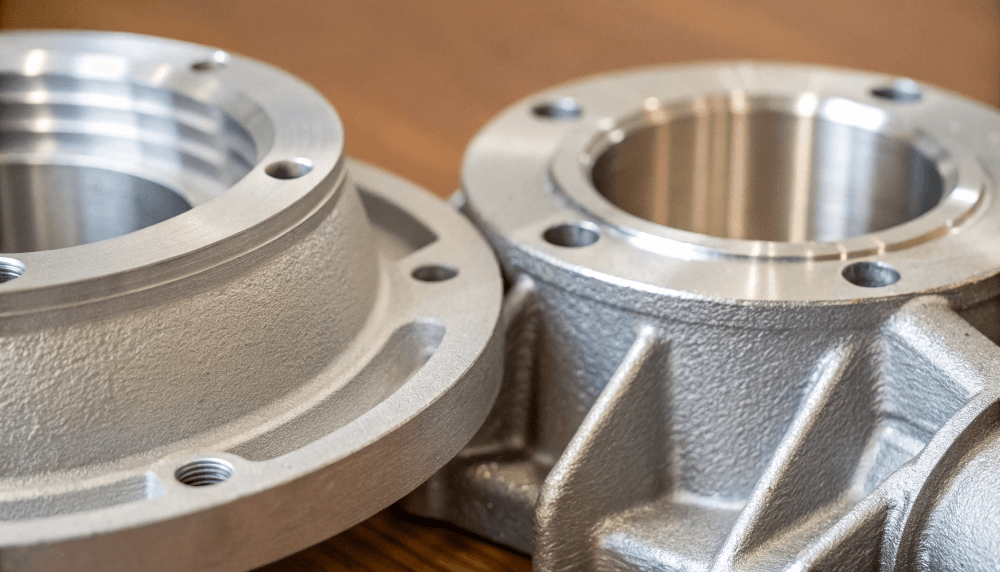

1. What Are Stainless Steel and Aluminum Castings?

Both stainless steel and aluminum castings are integral parts of modern manufacturing. These materials come with unique benefits that cater to different types of industrial applications.

Stainless steel castings are durable and resistant to corrosion, making them ideal for high-stress and high-temperature environments. On the other hand, aluminum castings are lightweight, have good thermal conductivity, and are cost-effective.

In this section, we will explore their definitions and key properties to help you understand what makes them suitable for various uses.

Stainless Steel Castings

Stainless steel is known for its ability to withstand harsh environments and high temperatures. This material is commonly used in industries where strength and corrosion resistance are critical.

- Durability: Stainless steel is highly resistant to wear and tear, making it a top choice for applications requiring long-lasting components.

- Corrosion Resistance: Stainless steel is resistant to rust, even in extreme conditions. This makes it ideal for outdoor and marine applications.

Aluminum Castings

Aluminum is a lightweight metal that offers versatility in terms of applications. It is commonly used in industries like automotive and aerospace, where weight reduction is essential.

- Lightweight: Aluminum is much lighter than stainless steel, making it an ideal choice for industries that need to reduce the weight of products.

- Thermal Conductivity: Aluminum has high thermal conductivity, making it a better option for heat transfer applications like radiators and cooling systems.

Table 1: Key Differences Between Stainless Steel and Aluminum Castings

| Property | Stainless Steel | Aluminum |

|---|---|---|

| Weight | Heavier | Lighter |

| Corrosion Resistance | High | Moderate |

| Thermal Conductivity | Moderate | High |

| Cost | Expensive | Affordable |

2. What Are the Advantages of Stainless Steel Castings?

When you need parts that can endure extreme temperatures or resist corrosion, stainless steel castings offer unmatched benefits.

Stainless steel is preferred for heavy-duty applications due to its superior durability and resistance to high temperatures. This makes it ideal for industries such as oil and gas, power generation, and marine environments.

In this section, we will look into why stainless steel castings might be the best choice for your project.

Advantages of Stainless Steel Castings

- High Strength and Durability: Stainless steel is known for its ability to withstand intense stress and pressure. This makes it the ideal material for components that require strength and longevity.

- Resistant to Extreme Temperatures: Stainless steel can resist high temperatures, which makes it suitable for industries like aerospace, automotive, and manufacturing.

- Corrosion Resistance: It offers superior protection against rust and corrosion, which is why it’s frequently used in marine and chemical industries.

Applications of Stainless Steel Castings

- Aerospace: Stainless steel is commonly used in parts like turbine blades and engine components, where durability and high performance are essential.

- Marine: Stainless steel’s resistance to saltwater corrosion makes it a popular choice for boat components.

Table 2: Industries Benefiting from Stainless Steel Castings

| Industry | Application Example | Key Advantage |

|---|---|---|

| Aerospace | Turbine blades | Heat resistance |

| Marine | Boat components | Corrosion resistance |

| Oil and Gas | Pump parts | Durability |

3. What Are the Advantages of Aluminum Castings?

Aluminum castings are widely regarded for their versatility and cost-effectiveness. When weight is a concern, aluminum is often the material of choice due to its lightweight nature and efficiency.

Aluminum castings offer a balance between strength and weight, which is crucial for industries focused on energy efficiency and performance.

Here’s a look at why you might choose aluminum for your casting needs.

Advantages of Aluminum Castings

- Lightweight: Aluminum castings are significantly lighter than stainless steel, making them ideal for industries where weight reduction is a priority.

- High Thermal Conductivity: Aluminum has excellent thermal conductivity, making it the preferred material for heat exchangers, radiators, and cooling systems.

- Cost-Effective: Aluminum castings are typically more affordable compared to stainless steel, making them a great option for projects with budget constraints.

Applications of Aluminum Castings

- Automotive: Aluminum is commonly used in engine blocks, wheels, and other car parts where reducing weight enhances fuel efficiency.

- Aerospace: Lightweight aluminum is used for aircraft parts, including structural components and engine components.

Table 3: Industries Benefiting from Aluminum Castings

| Industry | Application Example | Key Advantage |

|---|---|---|

| Automotive | Engine blocks | Lightweight |

| Aerospace | Aircraft parts | Fuel efficiency |

| HVAC | Heat exchangers | Thermal conductivity |

4. How Do Stainless Steel and Aluminum Compare in Terms of Strength?

Strength is a crucial factor when choosing materials for any manufacturing process. Stainless steel and aluminum both offer different strength profiles, which makes them suitable for different types of projects.

Stainless steel is known for its high tensile strength, while aluminum is generally more flexible but lacks the same strength levels as stainless steel.

In this section, we will compare the strength characteristics of both materials and see where each shines.

Tensile Strength Comparison

- Stainless Steel: Stainless steel is highly resistant to deformation under stress, making it an ideal material for high-load applications.

- Aluminum: While aluminum is not as strong as stainless steel, it still offers good tensile strength and can be used in lighter applications without sacrificing performance.

Impact and Fatigue Resistance

- Stainless Steel: It is more resistant to impact and fatigue, making it suitable for parts subjected to high stress and wear.

- Aluminum: Although aluminum is less resistant to impact than stainless steel, its light weight and ability to absorb energy make it ideal for certain applications.

Table 4: Strength Comparison of Stainless Steel and Aluminum

| Property | Stainless Steel | Aluminum |

|---|---|---|

| Tensile Strength | High | Moderate |

| Impact Resistance | High | Moderate |

| Fatigue Resistance | High | Moderate |

5. When Should You Choose Stainless Steel Castings Over Aluminum?

Understanding when to choose stainless steel castings over aluminum is essential for making the right material selection. While both materials have their unique strengths, there are specific scenarios where stainless steel may be the more appropriate choice.

When high strength, corrosion resistance, and high-temperature performance are your top priorities, stainless steel is often the material of choice. It provides durability and longevity, making it ideal for demanding applications.

Here are several factors to consider when opting for stainless steel castings over aluminum.

Best Scenarios for Choosing Stainless Steel Castings

- High-Temperature Environments: Stainless steel can withstand high temperatures without losing its structural integrity. It’s commonly used in industries like aerospace and energy, where components are exposed to extreme heat.

- Corrosion-Resistant Applications: If the component will be exposed to harsh chemicals, salty environments, or water, stainless steel is the better choice. Its corrosion resistance ensures long-term durability in marine, chemical, and food processing industries.

- Heavy Load and Pressure: For parts that must withstand heavy loads or are under constant pressure, stainless steel’s strength is unmatched. This makes it ideal for industrial machinery and structural components.

When to Prioritize Stainless Steel

- Structural Parts: Stainless steel is a natural choice for structural components, such as beams, columns, and supports, where strength is a critical factor.

- Components Exposed to Harsh Chemicals: For chemical processing equipment, stainless steel can handle exposure to strong acids and alkalis without deteriorating.

Table 5: Scenarios Where Stainless Steel is Preferred

| Application Area | Reason to Choose Stainless Steel | Example Components |

|---|---|---|

| High-temperature environments | Excellent heat resistance | Gas turbines, heat exchangers |

| Marine and coastal areas | Superior corrosion resistance | Boat components, sea pipelines |

| Heavy-duty machinery | High tensile strength and durability | Pumps, valves, industrial parts |

6. When Should You Choose Aluminum Castings Over Stainless Steel?

In some cases, the lightweight and cost-effective nature of aluminum makes it the better material choice. While it may not have the same strength as stainless steel, it offers advantages in industries where weight and thermal conductivity are critical.

Aluminum is ideal for applications that require weight reduction, good thermal performance, and where cost efficiency is key.

Let’s explore when aluminum castings should be preferred over stainless steel.

Best Scenarios for Choosing Aluminum Castings

- Lightweight Applications: When reducing weight is a priority, aluminum’s lightweight nature makes it the material of choice. It’s commonly used in automotive and aerospace components, where reducing weight improves efficiency and performance.

- Thermal Conductivity Needs: Aluminum excels in heat dissipation. If your project requires efficient heat transfer, such as in heat exchangers or electronic housings, aluminum is the superior choice.

- Cost-Efficiency: Aluminum castings are generally more affordable than stainless steel castings, making them ideal for projects with tight budgets.

When to Prioritize Aluminum

- Automotive and Aerospace: Aluminum castings are widely used in car engine parts, wheels, and airplane structural components. The reduction in weight directly benefits fuel efficiency and performance.

- Cooling Systems: Aluminum is commonly used for heat sinks, radiators, and other cooling components due to its high thermal conductivity.

Table 6: Scenarios Where Aluminum is Preferred

| Application Area | Reason to Choose Aluminum | Example Components |

|---|---|---|

| Automotive and aerospace | Lightweight for fuel efficiency | Engine parts, wheels |

| Cooling systems | High thermal conductivity | Heat exchangers, radiators |

| Budget-conscious projects | Lower cost and faster manufacturing | Housing parts, brackets |

7. How Does the Cost of Stainless Steel Castings Compare to Aluminum?

Cost is a significant consideration when choosing between stainless steel and aluminum castings. While aluminum generally has a lower material cost, the overall price depends on factors like the required strength, temperature tolerance, and production processes.

In many cases, aluminum castings are more affordable than stainless steel, but it’s important to consider the trade-offs between cost, performance, and the long-term durability of the material.

Let’s examine the cost comparison between the two materials.

Material Cost

- Stainless Steel: Stainless steel is typically more expensive than aluminum due to the high cost of raw materials and the complex manufacturing processes involved. Its price can vary depending on the specific alloy used and the required properties.

- Aluminum: Aluminum is generally more affordable and easier to cast, making it a more cost-effective option for many applications. The material is abundant and relatively inexpensive to process.

Manufacturing Cost

- Stainless Steel: The manufacturing process for stainless steel castings can be more expensive due to the need for specialized equipment and the difficulty of working with the material.

- Aluminum: Aluminum castings are quicker and cheaper to produce, particularly when using high-pressure die casting methods. This makes aluminum the preferred option for mass production.

Long-term Costs

- Stainless Steel: While stainless steel castings may have a higher initial cost, their durability and resistance to corrosion can result in lower maintenance and replacement costs over time.

- Aluminum: Aluminum castings may have lower upfront costs, but they may require more frequent maintenance or replacement in high-stress applications.

Table 7: Cost Comparison Between Stainless Steel and Aluminum Castings

| Factor | Stainless Steel | Aluminum |

|---|---|---|

| Material Cost | High | Low |

| Manufacturing Cost | Expensive | Affordable |

| Long-term Maintenance | Low (due to durability) | High (due to wear) |

8. What Are the Processing Techniques for Stainless Steel Castings?

The casting process for stainless steel is more complex than aluminum casting due to the material’s higher melting point and tendency to react with certain elements during the process.

Stainless steel casting involves high-precision techniques to ensure quality and performance, but it requires more careful handling and expertise.

Let’s explore the common methods used in stainless steel casting.

Common Stainless Steel Casting Methods

- Investment Casting: Also known as lost-wax casting, this method allows for high precision and is ideal for creating complex parts with fine details. It is often used in aerospace and medical device manufacturing.

- Sand Casting: A more affordable and common casting method that uses a sand mold. It’s suitable for producing large parts, though the precision is lower compared to investment casting.

- Die Casting: This method is used for producing high-volume, small to medium-sized parts. The stainless steel is injected into a mold under pressure.

Challenges in Processing Stainless Steel

- High Melting Point: Stainless steel requires higher temperatures for casting, which can lead to longer cycle times and higher energy costs.

- Reactivity: Some grades of stainless steel may react with mold materials, requiring special coatings to prevent contamination.

Table 8: Stainless Steel Casting Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Investment Casting | High precision, complex shapes | Expensive, slower cycle times |

| Sand Casting | Low cost, versatile | Lower precision, rough surface |

| Die Casting | High volume production | Limited to smaller parts |

9. What Are the Processing Techniques for Aluminum Castings?

Aluminum casting is more straightforward than stainless steel casting due to aluminum’s lower melting point and its ability to be easily shaped. Aluminum castings are widely used in various industries, including automotive, aerospace, and electronics, for their lightweight and versatile nature.

The casting techniques for aluminum are generally less complex and allow for faster, more efficient production compared to stainless steel.

Let’s examine the common processing methods for aluminum castings and the challenges associated with each.

Common Aluminum Casting Methods

- Die Casting: This is one of the most commonly used methods for aluminum castings. It involves forcing molten aluminum into a mold under high pressure, resulting in fast production of high-precision, complex parts. Die casting is ideal for mass production of small to medium-sized parts.

- Sand Casting: Sand casting is often used for larger aluminum parts. The process involves creating a mold from sand and then pouring molten aluminum into it. This method is cost-effective but can result in rougher surfaces and lower precision.

- Permanent Mold Casting: In this method, aluminum is poured into a reusable metal mold, which provides better surface finishes and more accurate results compared to sand casting. It is typically used for medium to high-volume production.

Advantages and Disadvantages of Aluminum Casting Methods

- Die Casting Advantages: High precision, fast production, and low-cost manufacturing in bulk.

- Sand Casting Advantages: Cost-effective for low-volume production of large parts.

- Permanent Mold Casting Advantages: Better surface finishes, good dimensional accuracy.

Table 9: Comparison of Aluminum Casting Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Die Casting | High precision, fast production | Expensive molds, limited part size |

| Sand Casting | Low cost, versatile | Lower precision, rough surface finish |

| Permanent Mold Casting | Good accuracy, surface finish | Higher cost, slower production |

10. How Do Stainless Steel and Aluminum Perform in Different Industries?

Both stainless steel and aluminum are highly sought-after materials across various industries. Their unique properties make them suitable for specific applications. Understanding how each material performs in different sectors can help you make an informed decision based on industry requirements.

Each industry has its specific needs, and the material selection often boils down to factors such as strength, weight, durability, and cost.

Let’s explore how stainless steel and aluminum perform in several major industries.

Stainless Steel in Various Industries

- Aerospace: Stainless steel is often used for engine components, turbine blades, and structural parts due to its high strength and resistance to extreme temperatures.

- Marine: Its resistance to corrosion makes stainless steel ideal for boats, submarines, and offshore structures exposed to seawater.

- Chemical Processing: Stainless steel’s resistance to corrosive chemicals and high heat makes it a popular choice for tanks, pipes, and pumps in chemical manufacturing.

Aluminum in Various Industries

- Automotive: Aluminum is frequently used in car bodies, engine parts, and wheels to reduce the overall weight, which improves fuel efficiency.

- Aerospace: Aluminum is used in airplane structures, wing components, and fuselages due to its lightweight nature.

- Electronics: Aluminum is commonly used in housings, heat sinks, and connectors due to its thermal conductivity and ease of machining.

Table 10: Performance of Stainless Steel and Aluminum in Different Industries

| Industry | Stainless Steel Use | Aluminum Use |

|---|---|---|

| Aerospace | Engine components, turbine blades | Aircraft parts, fuselages |

| Marine | Boat components, offshore structures | Lightweight hulls |

| Automotive | Exhaust systems, suspension parts | Engine blocks, wheels |

| Electronics | Electrical enclosures | Heat sinks, connectors |

11. How Does the Weight Difference Affect the Use of Castings?

The weight of the casting material plays a significant role in many engineering applications. Stainless steel is heavier than aluminum, which can have implications for the design, efficiency, and performance of products.

In industries where weight is a critical factor, such as automotive and aerospace, aluminum’s lightweight nature provides a competitive advantage. However, stainless steel’s strength may outweigh its weight in certain heavy-duty applications.

Weight in Product Design

- Lightweight Needs: For automotive and aerospace industries, every kilogram counts. Aluminum is often preferred in these sectors to reduce the overall weight of vehicles and aircraft, which improves fuel efficiency and performance.

- Heavy-Duty Requirements: In industries like construction and manufacturing, the weight of stainless steel can be an asset. Heavier components are often needed for structural integrity, where strength takes precedence over weight.

Impact of Weight on Efficiency

- Fuel Efficiency: Reducing weight in vehicles and airplanes can lead to improved fuel economy, which is why aluminum is heavily used in these industries.

- Strength vs. Weight: Stainless steel’s weight doesn’t hinder its effectiveness in applications where strength and durability are essential, such as in industrial machinery.

Table 11: Impact of Weight in Different Applications

| Industry | Use of Lightweight Aluminum | Use of Heavy Stainless Steel |

|---|---|---|

| Automotive | Body panels, engine blocks | Exhaust systems, suspension parts |

| Aerospace | Aircraft structure, fuselage | Engine components, turbine blades |

| Construction | Structural framing | Support beams, columns |

12. What Are the Environmental Considerations for Stainless Steel and Aluminum Castings?

Environmental sustainability is becoming an increasingly important factor in material selection. Both stainless steel and aluminum have their environmental pros and cons, which are worth considering when making a choice.

Stainless steel and aluminum both have good recycling rates, but aluminum’s lower energy requirements during production make it the more eco-friendly choice in many cases.

Let’s explore the environmental impact of both materials.

Recycling and Sustainability

- Stainless Steel: Stainless steel is fully recyclable, and the recycling process uses less energy compared to producing new stainless steel. However, its production still generates a significant amount of greenhouse gases.

- Aluminum: Aluminum is highly recyclable and requires only 5% of the energy to recycle compared to producing new aluminum. This makes it a more sustainable material in terms of energy consumption.

Energy Consumption and Emissions

- Stainless Steel: The production of stainless steel requires a considerable amount of energy, resulting in higher carbon emissions compared to aluminum.

- Aluminum: While aluminum production is energy-intensive, it’s still more energy-efficient to recycle than to produce from raw materials.

Table 12: Environmental Comparison of Stainless Steel and Aluminum

| Factor | Stainless Steel | Aluminum |

|---|---|---|

| Recyclability | 100% recyclable | 100% recyclable |

| Energy Consumption | High energy use in production | Lower energy use in recycling |

| Carbon Emissions | High emissions during production | Lower emissions when recycled |

13. How Do Stainless Steel and Aluminum Affect Product Life Cycle?

When choosing a material, it’s essential to consider the long-term impact on the product’s life cycle. Both stainless steel and aluminum offer different lifespans depending on the application, environment, and maintenance.

Stainless steel is often the better choice for products that need to endure wear, corrosion, and high temperatures for long periods. On the other hand, aluminum is perfect for applications where weight is key, but it may require more frequent replacement in harsh environments.

Durability and Longevity

- Stainless Steel: Stainless steel’s durability and resistance to corrosion contribute to longer product life cycles, particularly in heavy-duty applications.

- Aluminum: While aluminum is lightweight and cost-effective, it may require more frequent replacement or maintenance in harsh conditions due to its lower strength compared to stainless steel.

Maintenance Needs

- Stainless Steel: Stainless steel components require less frequent maintenance, reducing the total cost of ownership.

- Aluminum: Aluminum parts, while lighter and cheaper, may require more maintenance or replacements, especially in high-stress applications.

Table 13: Comparison of Product Life Cycle for Stainless Steel and Aluminum

| Material | Durability | Maintenance Frequency | Life Cycle Cost |

|---|---|---|---|

| Stainless Steel | High | Low | Higher initial cost, lower maintenance |

| Aluminum | Moderate | High | Lower initial cost, higher maintenance |

14. What Are Common Mistakes When Choosing Between Stainless Steel and Aluminum Castings?

Making the right material choice requires careful consideration. There are several common mistakes that can lead to suboptimal decisions in choosing between stainless steel and aluminum castings.

Understanding the differences and not focusing only on cost or strength will help you avoid the most common pitfalls in material selection.

Common Mistakes in Material Selection

- Focusing Only on Cost: While aluminum is cheaper, it may not be the best choice for every application. Considering factors like durability and strength can lead to better long-term results.

- Ignoring Environmental Conditions: Choosing the wrong material for the environment can lead to early degradation. Stainless steel is better for corrosive environments, while aluminum works well in lightweight applications.

- Not Considering Maintenance Needs: Some applications may require regular maintenance or part replacements. Choosing the right material for the long term can reduce maintenance costs.

Table 14: Mistakes to Avoid When Choosing Castings

| Mistake | Result | Best Practice |

|---|---|---|

| Focusing only on cost | Shorter product life | Consider strength, durability, and cost |

| Ignoring environmental factors | Rapid wear and corrosion | Choose based on environmental needs |

| Overlooking maintenance | Increased maintenance costs | Consider long-term durability |

15. How to Make the Right Choice Between Stainless Steel and Aluminum Castings?

Making the right choice between stainless steel and aluminum requires a clear understanding of your project’s specific needs. By analyzing factors such as strength, weight, temperature resistance, and cost, you can make an informed decision that will benefit your project in the long run.

The key to choosing the right material lies in understanding your application’s requirements and balancing those with the material’s properties and cost-effectiveness.

Steps for Making the Right Choice

- Assess the Application Requirements: Consider the weight, strength, and environmental factors involved in your project.

- Compare Material Properties: Understand the differences in thermal conductivity, corrosion resistance, and durability to select the material that meets your needs.

- Consult with Experts: For complex applications, it’s always a good idea to consult with a material expert to ensure the best choice for your project.

Table 15: Final Comparison of Stainless Steel vs. Aluminum for Key Factors

| Factor | Stainless Steel | Aluminum |

|---|---|---|

| Strength | High | Moderate |

| Weight | Heavy | Light |

| Corrosion Resistance | Excellent | Moderate |

| Cost | High | Low |

Conclusion

Choosing between stainless steel and aluminum castings depends on the specific needs of your project. Stainless steel excels in high-strength, high-temperature environments, while aluminum is a better option when weight and cost are critical factors. By carefully considering these factors, you can make an informed decision that will optimize the performance and cost-effectiveness of your products.

FAQ Section

Q1: What is the difference between stainless steel and aluminum castings?

Stainless steel is stronger and more resistant to corrosion, while aluminum is lighter and more cost-effective.

Q2: How does stainless steel casting work?

Stainless steel casting involves melting the steel and pouring it into molds to form parts that are used in a wide range of applications requiring durability.

Q3: Why would you choose aluminum castings over stainless steel?

Aluminum is preferred for lightweight components and applications requiring good thermal conductivity, such as automotive and aerospace industries.

Q4: Are aluminum castings more cost-effective than stainless steel?

Yes, aluminum castings are generally more affordable both in terms of material and manufacturing costs.

Q5: Can stainless steel castings be used in high-temperature environments?

Yes, stainless steel castings are highly resistant to heat, making them ideal for industries that require parts that can withstand extreme temperatures.