What Are High-Temperature Alloys?

High-temperature alloys are engineered materials designed to endure extreme environments, particularly elevated temperatures, high stress, and corrosive conditions. These alloys combine metals like nickel, cobalt, and iron with elements such as chromium, aluminum, and molybdenum to achieve superior mechanical and chemical stability. Their exceptional heat resistance makes them indispensable in industries where standard materials would fail. These alloys not only enable advanced engineering but also enhance efficiency and safety in various applications. Whether in aerospace, automotive, or energy production, high-temperature alloys drive innovation and reliability in demanding scenarios, showcasing their importance in modern industry.

Understanding High-Temperature Alloys

Definition and Composition

High-temperature alloys, often referred to as superalloys, are a category of materials explicitly crafted to function in conditions where ordinary metals would degrade. These alloys derive their strength from a precise combination of metals like nickel, cobalt, or iron, which serve as their base, and additional elements such as chromium, molybdenum, and titanium. Each constituent contributes to the alloy’s unique properties. For instance, nickel ensures excellent thermal stability, while chromium enhances corrosion resistance. Together, these elements create a synergy that results in materials capable of withstanding extreme environments.

Key Properties

The remarkable performance of high-temperature alloys can be attributed to their distinct properties. Thermal stability allows them to maintain structural integrity at temperatures exceeding 1,000°C, crucial in applications like jet engines and turbines. Their corrosion resistance prevents oxidation and chemical degradation in hostile environments, such as those found in power plants or chemical industries. Additionally, these alloys exhibit exceptional mechanical strength, making them ideal for applications involving significant stress and wear. These features position high-temperature alloys as a critical material class in numerous high-performance industries.

Common Types of High-Temperature Alloys

Several categories of high-temperature alloys exist, each tailored to specific applications. Nickel-based superalloys dominate the aerospace and energy sectors due to their unmatched thermal and corrosion resistance. Cobalt-based alloys, known for their wear resistance, are preferred in cutting tools and medical applications. Iron-based superalloys, though less thermally resistant, find utility in applications requiring cost efficiency and moderate performance. The diversity within this material class ensures a solution for nearly every engineering challenge involving extreme conditions.

How They Differ From Conventional Materials

Unlike standard metals, high-temperature alloys are not limited by low melting points or susceptibility to deformation under high stress. While traditional materials like aluminum or steel soften or oxidize at elevated temperatures, high-temperature alloys remain robust and chemically stable. This distinction extends their applicability to environments where safety, longevity, and performance are non-negotiable. The development of these materials represents a leap forward in materials science, addressing limitations that hindered industrial progress for decades.

Historical Context

When Did High-Temperature Alloys Emerge?

The evolution of high-temperature alloys traces back to the early 20th century, coinciding with advancements in aviation and energy technologies. The demand for materials capable of withstanding high thermal and mechanical stress grew as industries sought to push boundaries. The introduction of nickel-based alloys in the 1940s marked a turning point. These materials revolutionized turbine engines, enabling sustained high-performance operations. Over the decades, continuous research and innovation have refined these alloys, expanding their utility across diverse fields.

Key Innovations in the Field

Several milestones define the journey of high-temperature alloys. The discovery of precipitation hardening, a process enhancing mechanical properties through heat treatment, significantly improved their performance. Advances in alloying techniques, such as the addition of rare earth elements, have further optimized their properties. For instance, modern turbine blades utilize single-crystal nickel superalloys, eliminating grain boundaries and enhancing creep resistance. These innovations underscore the relentless pursuit of excellence in materials science, ensuring high-temperature alloys remain at the forefront of industrial progress.

Early Applications and Their Impact

The initial use of high-temperature alloys in military jet engines during World War II demonstrated their potential. These engines, operating at unprecedented temperatures, required materials that could endure harsh conditions without failure. The success of these early applications paved the way for broader adoption in commercial aviation, power generation, and beyond. High-temperature alloys not only enabled technological advancements but also laid the foundation for industries that rely on performance under extreme conditions.

Industry Dependence on High-Temperature Alloys

Today, industries from aerospace to healthcare rely on high-temperature alloys to achieve their objectives. The dependence is evident in the growing investment in research and development aimed at refining these materials. Innovations continue to address challenges, ensuring these alloys meet evolving industrial needs. Their historical significance and ongoing development highlight their indispensable role in modern engineering and manufacturing.

Aerospace Industry Applications

Why Are High-Temperature Alloys Crucial in Aerospace?

The aerospace sector demands materials that can withstand extreme temperatures, high stress, and corrosive environments, all while maintaining a lightweight profile. High-temperature alloys meet these criteria, making them the backbone of aviation and space exploration. Jet engines, for instance, operate at temperatures well above 1,000°C, necessitating materials that resist deformation and oxidation. High-temperature alloys not only enable such performance but also enhance fuel efficiency and safety, critical factors in aerospace engineering.

Examples of Usage

High-temperature alloys find diverse applications within the aerospace sector. Turbine blades and vanes, exposed to intense heat and pressure, rely on these materials for durability and efficiency. Exhaust systems, which face thermal cycling and chemical exposure, benefit from the corrosion resistance of high-temperature alloys. In spacecraft, components like heat shields and propulsion systems utilize these alloys to withstand the harsh conditions of space. Their versatility and performance underscore their value in aerospace engineering.

Case Studies

The role of high-temperature alloys in aerospace can be illustrated through landmark projects. The development of the Pratt & Whitney F119 engine for the F-22 Raptor, for example, showcases their application in cutting-edge military technology. Similarly, the Mars rover Curiosity utilizes high-temperature alloys in its power systems, ensuring functionality in the extreme conditions of the Martian environment. These cases highlight how high-temperature alloys enable technological breakthroughs in aerospace.

Benefits Beyond Performance

Beyond technical performance, high-temperature alloys contribute to sustainability in aerospace. By enabling higher operating temperatures, these materials improve fuel efficiency, reducing emissions and environmental impact. Their durability also minimizes maintenance needs, lowering costs and enhancing operational reliability. The aerospace sector’s reliance on high-temperature alloys reflects their unparalleled ability to meet the demanding requirements of modern aviation and space exploration.

Automotive Industry

Enhancing Vehicle Performance

The automotive industry leverages high-temperature alloys to improve performance, efficiency, and durability. Internal combustion engines, for example, utilize these materials in turbochargers and exhaust manifolds to withstand high temperatures and pressures. This not only enhances engine efficiency but also extends component lifespan. Additionally, high-temperature alloys contribute to vehicle safety by maintaining structural integrity under extreme conditions, such as high-speed operations or thermal cycling.

Electric Vehicles (EVs): A New Frontier

Electric vehicles (EVs) represent a growing segment of the automotive market, and high-temperature alloys play a crucial role in their development. Battery protection systems, for instance, rely on these materials to endure high temperatures during charging and discharging cycles. Electric motors, which operate under significant thermal stress, benefit from the thermal stability and electrical conductivity of high-temperature alloys. As the demand for EVs grows, the role of these materials in advancing automotive technology becomes increasingly important.

Applications in Motorsport

Motorsport, with its emphasis on performance and precision, highlights the potential of high-temperature alloys. Components like exhaust systems, brake rotors, and suspension parts utilize these materials to achieve weight reduction, thermal resistance, and enhanced durability. The competitive nature of motorsport drives innovation, with advancements in high-temperature alloys often trickling down to commercial automotive applications.

Cost Considerations in Automotive Applications

While high-temperature alloys offer undeniable benefits, their cost remains a consideration in the automotive industry. Manufacturers balance performance gains against material expenses, often opting for alloys in critical components where their properties provide the greatest value. Advances in manufacturing techniques, such as additive manufacturing, are helping to reduce costs, making these materials more accessible for a wider range of applications.

Energy Sector Applications

Power Generation

The energy sector depends on high-temperature alloys to enhance efficiency and reliability in power generation. Gas turbines, which operate at extreme temperatures, rely on these materials for components like blades, vanes, and combustion chambers. By enabling higher operating temperatures, high-temperature alloys improve thermal efficiency, reducing fuel consumption and emissions. In nuclear power plants, these alloys provide the strength and corrosion resistance needed for reactor components exposed to intense radiation and heat.

Oil and Gas Industry

In the oil and gas sector, high-temperature alloys are essential for equipment exposed to harsh environments. Downhole tools, used in drilling and extraction, face high temperatures, pressures, and corrosive conditions. High-temperature alloys ensure these tools maintain their integrity and performance, reducing downtime and operational risks. Refinery equipment, such as heat exchangers and distillation columns, also benefits from the corrosion resistance of these materials, enhancing efficiency and safety.

Renewable Energy Applications

The transition to renewable energy sources has expanded the application of high-temperature alloys. In solar thermal plants, these materials are used in receivers and heat exchangers to capture and transfer energy efficiently. Wind turbines, particularly in offshore environments, rely on high-temperature alloys for components exposed to corrosive marine conditions. Hydrogen production and storage systems also utilize these materials to address the challenges of high-pressure and high-temperature environments.

Future Trends in the Energy Sector

The energy sector’s reliance on high-temperature alloys is set to grow as industries strive for greater efficiency and sustainability. Advances in material science, such as the development of alloys with enhanced thermal conductivity and reduced environmental impact, are poised to drive further innovation. These trends highlight the ongoing importance of high-temperature alloys in meeting the evolving needs of the energy industry.

Healthcare and Medical Uses

Precision in Extreme Conditions

The healthcare and medical sectors require materials that combine biocompatibility with the ability to endure extreme conditions. High-temperature alloys excel in these applications due to their exceptional mechanical properties and resistance to wear, corrosion, and repeated sterilization. Medical devices and implants often operate in demanding environments, whether within the human body or in external sterilization equipment. High-temperature alloys provide the strength and durability needed for tools and devices that must perform flawlessly over extended periods.

Applications in Medical Implants and Devices

One prominent use of high-temperature alloys is in medical implants such as hip and knee replacements. These components must endure constant stress and friction while maintaining biocompatibility to avoid adverse reactions. Titanium alloys, a subset of high-temperature materials, are commonly used in this context. Additionally, high-temperature alloys are integral to surgical tools like scalpels and forceps, where precision and durability are critical. Diagnostic equipment, including imaging machines and endoscopic devices, also incorporates these alloys to ensure long-term functionality.

Why High-Temperature Alloys Are Essential

The medical field demands reliability, particularly when lives are at stake. High-temperature alloys offer unparalleled resistance to wear and tear, even under intense operational stress. For example, components in advanced imaging systems must maintain performance despite high-energy exposure during procedures like MRIs and CT scans. Similarly, alloys used in heart valves or stents must resist fatigue and degradation within the body’s hostile biochemical environment.

Innovations in Medical Applications

Recent advancements have expanded the scope of high-temperature alloys in medicine. Additive manufacturing, or 3D printing, enables the creation of customized implants and devices tailored to individual patients. High-temperature alloys are ideal for this process due to their ability to retain structural integrity during complex manufacturing steps. Furthermore, research into alloy coatings enhances their performance by improving wear resistance and reducing friction. These innovations continue to transform the medical landscape.

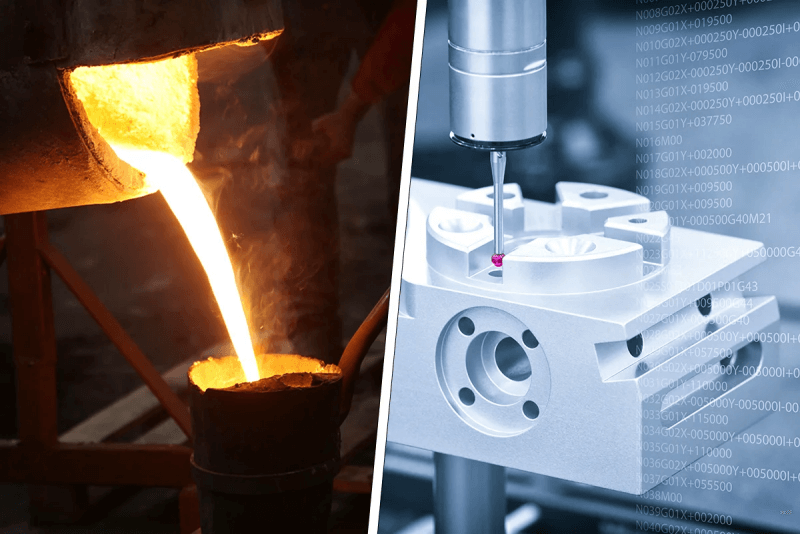

Industrial Equipment and Manufacturing

Applications in Heavy Machinery

Industrial equipment operating in high-temperature environments relies on materials that can withstand extreme conditions without compromising performance. High-temperature alloys are widely used in manufacturing processes, particularly in machinery like furnaces, molds, and heat exchangers. These alloys ensure that equipment can handle prolonged exposure to elevated temperatures, heavy loads, and corrosive substances, making them indispensable in heavy industries.

Durability as a Cost-Saving Measure

One of the key benefits of high-temperature alloys in manufacturing is their durability. By minimizing wear and tear, these materials reduce the frequency of repairs and replacements, leading to significant cost savings over time. For example, molds used in die-casting must endure rapid temperature fluctuations. High-temperature alloys maintain their shape and strength under such conditions, ensuring consistent product quality and reducing downtime.

Enhancing Manufacturing Efficiency

High-temperature alloys also contribute to manufacturing efficiency by enabling faster production cycles. Components like rollers and cutting tools made from these materials can operate at higher speeds and temperatures without degrading. This capability allows manufacturers to increase output while maintaining precision and quality. The result is a more efficient production process that meets the demands of modern industries.

Challenges in Manufacturing Processes

Despite their advantages, high-temperature alloys present challenges in manufacturing. Their hardness and thermal stability make machining and forming more difficult, requiring specialized tools and techniques. Welding these alloys can also be complex, as maintaining the material’s properties during joining processes demands precise control. Nevertheless, ongoing advancements in manufacturing technology, such as laser-based machining, are helping to overcome these challenges.

Chemical and Petrochemical Industries

Corrosive and High-Temperature Environments

The chemical and petrochemical industries face some of the most challenging environments, where materials are exposed to high temperatures, pressures, and corrosive substances. High-temperature alloys excel in these conditions, providing the strength and stability needed for critical equipment like reactors, heat exchangers, and piping systems. Their resistance to oxidation and chemical attack ensures long-term reliability and safety.

Ensuring Safety and Longevity

Safety is paramount in chemical and petrochemical facilities, where equipment failure can have catastrophic consequences. High-temperature alloys play a vital role in minimizing risks by maintaining their integrity under extreme conditions. For example, pressure vessels constructed from these materials can withstand intense stress and chemical exposure, reducing the likelihood of leaks or failures. Their longevity also lowers maintenance costs and minimizes disruptions to operations.

Specialized Applications

High-temperature alloys are used in specialized applications such as catalyst supports, where they must endure high thermal and mechanical loads. In petrochemical refining, distillation columns and cracking units rely on these materials to maintain efficiency and performance over prolonged operational cycles. The versatility of high-temperature alloys allows them to meet the diverse needs of chemical processing and refining industries.

Advancements in Alloy Technology

Recent advancements in alloy technology have further enhanced their suitability for chemical and petrochemical applications. Innovations in alloy composition, such as the addition of rare earth elements, have improved their resistance to wear and corrosion. Coating technologies also extend the lifespan of components by providing additional protection against aggressive environments. These developments ensure that high-temperature alloys remain at the forefront of industrial materials.

Emerging Fields and Innovations

Additive Manufacturing (3D Printing)

Additive manufacturing has revolutionized the use of high-temperature alloys, enabling the creation of complex geometries that were previously unattainable. This technology is particularly valuable in aerospace and medical applications, where precision and customization are critical. High-temperature alloys are well-suited for 3D printing due to their ability to maintain structural integrity during the manufacturing process, opening new possibilities for innovative designs.

Renewable Energy Applications

As the world transitions toward renewable energy sources, high-temperature alloys are finding new applications in wind, solar, and hydrogen technologies. In wind turbines, these materials provide durability and resistance to fatigue in components like bearings and gears. Solar thermal plants utilize high-temperature alloys in receivers and piping systems to handle the intense heat generated during energy capture. Additionally, hydrogen production and storage systems rely on these alloys to ensure safety and efficiency in high-pressure environments.

Advanced Coatings and Surface Treatments

Innovations in surface treatments have expanded the capabilities of high-temperature alloys. Coatings that enhance wear resistance, thermal stability, and corrosion protection allow these materials to perform in even more demanding conditions. For instance, turbine blades with advanced coatings can operate at higher temperatures, improving efficiency and reducing fuel consumption in power generation and aerospace applications.

The Future of High-Temperature Alloys

The future of high-temperature alloys lies in continuous innovation and refinement. Researchers are exploring new alloy compositions and manufacturing techniques to address challenges like cost and environmental impact. The integration of artificial intelligence and machine learning in materials science promises to accelerate the discovery of next-generation high-temperature alloys, ensuring their relevance in an ever-changing industrial landscape.

Selection Criteria for Industries

How to Choose the Right Alloy?

Selecting the appropriate high-temperature alloy depends on several factors, including operating temperature, environmental conditions, and mechanical stress. Industries must evaluate these criteria to identify materials that meet their specific needs. For instance, aerospace applications prioritize thermal stability and weight reduction, while the chemical industry emphasizes corrosion resistance.

Cost vs. Performance

Balancing cost and performance is a critical consideration when selecting high-temperature alloys. While these materials offer superior properties, their higher cost can be a barrier for some applications. Industries often focus on critical components where the benefits of high-temperature alloys outweigh the initial investment. Advances in manufacturing processes are helping to lower costs, making these materials more accessible.

Industry-Specific Needs

Each industry has unique requirements that influence the choice of high-temperature alloys. For example, the automotive industry prioritizes lightweight materials to improve fuel efficiency, while the energy sector focuses on materials that enhance thermal efficiency. Understanding these needs ensures that high-temperature alloys are used effectively and efficiently.

Supporting Research and Development

Ongoing research and development play a crucial role in expanding the capabilities of high-temperature alloys. Collaboration between industries, academic institutions, and material scientists drives innovation, addressing challenges and unlocking new applications. By investing in R\&D, industries can ensure that high-temperature alloys continue to meet evolving demands.

FAQs About High-Temperature Alloys

What industries benefit the most from high-temperature alloys?

Industries like aerospace, energy, automotive, and healthcare rely heavily on these materials for their exceptional performance in extreme conditions.

How are high-temperature alloys maintained or recycled?

Regular maintenance involves inspecting for wear and corrosion, while recycling often includes re-melting and reprocessing to recover valuable elements.

Are there sustainable alternatives to high-temperature alloys?

While ongoing research explores alternative materials, high-temperature alloys remain unmatched in performance, especially for demanding applications.

Conclusion

High-temperature alloys are the unsung heroes of modern industry, enabling progress and innovation across aerospace, energy, healthcare, and more. Their unique properties make them indispensable in environments where other materials fall short. As industries evolve, so too will the applications and advancements of these remarkable materials. By understanding and leveraging the capabilities of high-temperature alloys, businesses can drive efficiency, safety, and sustainability in their operations. For those seeking to enhance their systems or develop groundbreaking solutions, high-temperature alloys offer the perfect foundation.