China has emerged as a global leader in the casting industry, particularly in carbon steel and investment casting. Known for its high-quality standards, advanced technology, and cost-effective solutions, China has become a preferred destination for businesses worldwide seeking reliable casting services. In this comprehensive guide, we will explore the many reasons why choosing China for your carbon steel and investment casting needs can be a strategic decision for your business.

Understanding Carbon Steel and Investment Casting

What is Carbon Steel Casting?

Carbon steel casting is a process that involves pouring molten carbon steel into a mold to create complex shapes and designs. Carbon steel, an alloy made primarily of iron and carbon, is known for its strength, ductility, and toughness. The properties of carbon steel make it a popular choice in a wide range of industries, from automotive and construction to heavy machinery and industrial equipment.

There are several grades of carbon steel, each varying in carbon content and mechanical properties:

- Low Carbon Steel: Contains less than 0.3% carbon and is known for its excellent ductility and weldability. It is commonly used in applications where strength is not the primary concern, such as in automotive body panels and pipelines.

- Medium Carbon Steel: Contains 0.3% to 0.6% carbon and offers a balance between strength and ductility. It is often used in manufacturing gears, axles, and shafts.

- High Carbon Steel: Contains more than 0.6% carbon, providing superior strength and hardness. However, it is less ductile and more challenging to weld. High carbon steel is typically used for cutting tools, springs, and high-strength wires.

- Ultra-High Carbon Steel: Contains more than 1.25% carbon and is extremely hard and brittle. This type of steel is used for specialized applications that require maximum wear resistance, such as cutting tools and industrial knives.

What is Investment Casting?

Investment casting, also known as lost wax casting, is a precision casting process used to create intricate and complex metal parts. This method involves creating a wax pattern of the desired part, which is then coated with a ceramic shell. Once the ceramic shell hardens, the wax is melted out, leaving a mold that is filled with molten metal to produce the final casting.

Investment casting is highly versatile and can be used to cast a wide range of metals, including steel, aluminum, iron, and various alloys. It is particularly valued for its ability to produce parts with excellent surface finish, tight tolerances, and intricate details that would be difficult or impossible to achieve with other casting methods.

Applications of Carbon Steel and Investment Casting

Both carbon steel casting and investment casting are used in a variety of industries due to their versatility and ability to produce high-quality parts. Some of the common applications include:

- Automotive Industry: Carbon steel castings are used in engine components, suspension parts, and exhaust systems, while investment casting is employed to produce precision components like turbochargers and fuel injectors.

- Aerospace Industry: Investment casting is widely used to manufacture complex parts for aircraft engines and landing gear, where precision and high strength are critical.

- Construction Industry: Carbon steel castings are used in the construction of bridges, buildings, and other infrastructure projects due to their durability and strength.

- Machinery and Industrial Equipment: Both casting methods are used to produce a variety of machine parts, including gears, valves, pumps, and bearings, which require high strength and wear resistance.

By understanding the fundamental differences and applications of carbon steel and investment casting, businesses can make informed decisions about which casting method best suits their specific needs. In the following sections, we will delve deeper into the global landscape of the casting industry and explore why China is a leading choice for carbon steel and investment casting services.

The Global Landscape of Carbon Steel and Investment Casting

Overview of the Global Market

The global market for carbon steel and investment casting is vast and diverse, encompassing numerous industries and applications. As manufacturing demands continue to grow, so does the need for high-quality casting services that can deliver reliable, precise, and cost-effective solutions. Over the past few decades, there has been a significant shift in the dynamics of the casting industry, with many companies looking to offshore their casting needs to countries with established expertise and competitive pricing.

Traditionally, countries like the United States, Germany, and Japan have been at the forefront of the casting industry, known for their advanced technology and strict quality control measures. However, in recent years, China has emerged as a dominant player in the market. China’s rise to prominence is due to its ability to offer a combination of high-quality standards, innovative technology, and cost-effective production, making it a preferred destination for companies around the globe.

Major Players in the Industry

Today, China stands as one of the leading countries in the global casting industry, particularly in carbon steel and investment casting. Other significant players include India, the United States, Germany, and Japan, each with its unique strengths and market share.

- China: As the largest producer and exporter of castings, China has a well-established reputation for providing both carbon steel and investment casting services. Chinese foundries have invested heavily in modern equipment, skilled labor, and quality control measures, enabling them to produce castings that meet international standards.

- India: India is another major player in the casting industry, known for its robust manufacturing base and skilled workforce. The country has made significant strides in recent years to improve its casting capabilities and is becoming an increasingly attractive option for companies looking to outsource casting services.

- United States: The United States has a long history of casting production and remains a key player in the industry. American foundries are known for their innovation, particularly in high-precision investment casting, and continue to serve a broad range of industries, including aerospace, automotive, and defense.

- Germany and Japan: Both countries are recognized for their advanced technology and commitment to quality. German and Japanese foundries specialize in high-precision casting and are known for their ability to produce complex parts with tight tolerances.

Why Companies Outsource Casting Services

Outsourcing casting services has become a common practice for many companies worldwide, primarily due to the need for cost savings, access to advanced technology, and the ability to focus on core competencies. There are several key reasons why companies choose to outsource their casting needs:

- Cost Savings: By outsourcing to countries like China, companies can benefit from lower labor and production costs, resulting in significant cost savings. This is particularly important for businesses that operate in competitive markets and need to maintain cost-effectiveness.

- Access to Advanced Technology and Expertise: Many countries, including China, have invested heavily in modern casting technology and equipment. By outsourcing, companies can access the latest innovations and expertise without the need to invest in expensive machinery or specialized personnel.

- Scalability and Flexibility: Outsourcing allows companies to scale their production up or down based on demand without the burden of managing a large manufacturing facility. This flexibility is crucial for businesses that experience fluctuations in demand or need to respond quickly to market changes.

- Focus on Core Competencies: By outsourcing non-core activities like casting, companies can focus on their core competencies and strategic goals. This enables them to allocate resources more effectively and enhance overall productivity.

Given these advantages, it’s clear why outsourcing casting services to countries like China has become an attractive option for many businesses. In the next section, we will explore why China specifically has become a preferred choice for carbon steel and investment casting services.

Why Choose China for Carbon Steel and Investment Casting Services?

History of Casting in China

China has a long and rich history in casting, dating back thousands of years. The country has been producing metal castings since the Shang Dynasty, around 1600-1046 BCE, when the Chinese developed advanced techniques for casting bronze. This expertise has been passed down through generations, and today, China is recognized as a global leader in the casting industry.

Over the past few decades, China has made significant investments in modernizing its casting industry. The country has built state-of-the-art foundries, invested in advanced equipment and technology, and developed a skilled workforce capable of producing high-quality castings for a wide range of industries. This combination of historical expertise and modern innovation has positioned China as a leading provider of casting services.

Current Market Position

China’s position in the global casting market is unparalleled. The country is the largest producer and exporter of castings, with a market share that continues to grow. According to industry reports, China produces more than 40 million tons of castings annually, accounting for nearly half of the world’s total casting output. This remarkable production capacity is supported by a vast network of foundries, many of which are equipped with the latest technology and adhere to stringent quality standards.

Chinese foundries serve a diverse range of industries, including automotive, aerospace, construction, and machinery, and have built a reputation for delivering high-quality castings that meet the needs of customers worldwide. The country’s ability to produce large volumes of castings at competitive prices has made it a preferred choice for businesses looking to outsource their casting needs.

Reputation for Quality and Innovation

One of the key reasons why companies choose China for their casting needs is the country’s reputation for quality and innovation. Chinese foundries have made significant strides in recent years to improve the quality of their castings and adopt the latest technological advancements. Many Chinese foundries are now equipped with modern equipment, such as computer-controlled furnaces, automated molding lines, and advanced inspection systems, which enable them to produce castings with high precision and consistency.

In addition to technological innovation, Chinese foundries also place a strong emphasis on quality control. Many foundries adhere to international quality standards, such as ISO 9001, ISO 14001, and IATF 16949, and have implemented rigorous quality control measures to ensure that their castings meet the highest standards of quality and reliability. This commitment to quality has helped Chinese foundries build a strong reputation for delivering castings that meet the needs of customers around the globe.

In the following sections, we will delve deeper into the specific advantages of sourcing carbon steel and investment casting from China, including cost-effectiveness, quality, production capacity, and more.

Advantages of Sourcing Carbon Steel and Investment Casting from China

Senior Casting Ability

China’s casting industry is renowned for its senior casting ability, which is supported by a combination of modern production bases, experienced engineers, and skilled workers. The country has a rich tradition of casting, and its foundries have developed a deep understanding of the casting process, enabling them to produce high-quality castings with precision and consistency.

Chinese foundries are equipped with state-of-the-art equipment and technology, including computer-controlled furnaces, automated molding lines, and advanced inspection systems. This modern infrastructure allows Chinese foundries to produce castings with tight tolerances and intricate details, making them suitable for a wide range of applications.

In addition to their advanced equipment, Chinese foundries also benefit from a highly skilled workforce. The country’s casting industry employs thousands of engineers and skilled workers who have extensive experience in the field. These professionals undergo continuous training to stay up-to-date with the latest advancements in casting technology and techniques, ensuring that they can deliver castings that meet the highest standards of quality and performance.

Strict Quality System

Quality is a top priority for Chinese foundries, and many have implemented strict quality control systems to ensure that their castings meet international standards. Chinese foundries adhere to a range of quality standards, including ISO 9001, ISO 14001, and IATF 16949, and undergo regular audits to maintain their certifications.

Chinese foundries use a variety of quality control measures to ensure the consistency and reliability of their castings. These measures include:

- Material Testing: Incoming raw materials are tested for chemical composition and mechanical properties to ensure that they meet the required specifications.

- Process Control: The casting process is closely monitored to ensure that it is carried out according to the established procedures. This includes controlling the temperature of the molten metal, monitoring the pouring process, and ensuring that the molds are properly prepared.

- Inspection and Testing: Finished castings undergo a range of inspections and tests, including visual inspection, dimensional measurement, and non-destructive testing (NDT) methods such as X-ray, ultrasonic, and magnetic particle inspection. These tests help to identify any defects or inconsistencies in the castings and ensure that they meet the required specifications.

By adhering to strict quality standards and implementing rigorous quality control measures, Chinese foundries have built a reputation for delivering high-quality castings that meet the needs of customers worldwide.

Cost-Effectiveness

One of the primary reasons why companies choose China for their casting needs is the cost-effectiveness of Chinese foundries. China offers several advantages that contribute to lower production costs, including:

- Lower Labor Costs: Labor costs in China are generally lower than in many other countries, allowing Chinese foundries to offer competitive pricing without compromising on quality.

- Economies of Scale: China’s casting industry is characterized by large-scale production, which allows foundries to achieve economies of scale. By producing large volumes of castings, Chinese foundries can reduce the cost per unit, resulting in significant cost savings for customers.

- Access to Raw Materials: China has abundant natural resources, including a wide range of metals and alloys used in casting. This availability of raw materials helps to reduce the cost of production and ensures a stable supply of materials for Chinese foundries.

Sufficient Material Supply

China’s abundant natural resources provide a significant advantage for its casting industry. The country has a plentiful supply of metals and alloys, including steel, aluminum, iron, and various other materials used in both carbon steel and investment casting. This availability of raw materials ensures that Chinese foundries can meet the diverse needs of their customers and provide castings that are made from high-quality materials.

In addition to the availability of raw materials, China also has a well-established supply chain that supports the casting industry. This supply chain includes a network of suppliers, distributors, and logistics providers that work together to ensure a steady flow of materials and components to Chinese foundries. This efficient supply chain helps to reduce lead times and ensures that foundries can deliver castings on time and within budget.

Production Capacity and Efficiency

China’s casting industry is characterized by its high production capacity and efficiency. The country has a vast network of foundries, many of which are equipped with modern equipment and technology that enable them to produce large volumes of castings quickly and efficiently.

Chinese foundries are capable of handling large orders and meeting tight deadlines, making them an ideal choice for businesses that require high volumes of castings in a short period. This production capacity is supported by a combination of advanced technology, skilled labor, and efficient supply chain management, which allows Chinese foundries to deliver castings that meet the needs of their customers.

In addition to their high production capacity, Chinese foundries also offer flexible manufacturing capabilities. They can produce a wide range of castings, from small, intricate parts to large, complex components, and can adapt their production processes to meet the specific requirements of their customers. This flexibility makes Chinese foundries an attractive option for businesses that need custom castings or have unique design specifications.

Logistical Advantages

China’s strategic location and robust infrastructure provide significant logistical advantages for businesses looking to source castings from the country. China is located at the crossroads of major shipping routes, making it an ideal hub for international trade. The country has a well-developed network of ports, highways, and railways that support the efficient movement of goods, both domestically and internationally.

In addition to its strategic location, China also has a robust infrastructure that supports its casting industry. The country has invested heavily in modernizing its transportation and logistics networks, ensuring that foundries can quickly and efficiently deliver castings to customers around the globe. This infrastructure, combined with China’s efficient supply chain management, helps to reduce lead times and ensure that castings are delivered on time and within budget.

In the next section, we will address some of the common concerns that businesses may have about sourcing casting services from China, including quality assurance, intellectual property protection, and communication barriers.

Addressing Common Concerns About Chinese Casting Services

Quality Assurance

Quality assurance is a critical concern for businesses looking to source castings from any supplier, and China is no exception. However, it’s important to note that Chinese foundries have made significant strides in recent years to improve the quality of their castings and address any concerns about consistency and reliability.

Chinese foundries have implemented rigorous quality control measures to ensure that their castings meet the highest standards of quality and performance. These measures include:

- Adherence to International Standards: Many Chinese foundries adhere to international quality standards, such as ISO 9001, ISO 14001, and IATF 16949. These certifications demonstrate a commitment to quality and provide assurance that the foundry’s processes and procedures meet global standards.

- Regular Audits and Inspections: Chinese foundries undergo regular audits and inspections to ensure that they are maintaining their certifications and adhering to the required quality standards. These audits help to identify any areas for improvement and ensure that the foundry’s quality control measures are effective.

- Continuous Improvement: Chinese foundries are committed to continuous improvement and regularly invest in new equipment, technology, and training to enhance their casting capabilities. This commitment to improvement helps to ensure that Chinese foundries can deliver castings that meet the needs of their customers and exceed their expectations.

By implementing these quality control measures and adhering to international standards, Chinese foundries have built a reputation for delivering high-quality castings that meet the needs of customers worldwide.

Intellectual Property Protection

Intellectual property protection is another common concern for businesses looking to source castings from China. However, it’s important to note that China has made significant progress in recent years to strengthen its intellectual property laws and protect the rights of businesses and individuals.

China’s legal framework includes a range of laws and regulations designed to protect intellectual property, including patents, trademarks, and copyrights. These laws provide a legal basis for businesses to protect their designs, inventions, and other intellectual property from unauthorized use or infringement.

In addition to the legal framework, many reputable Chinese foundries have implemented their own policies and procedures to protect their customers’ intellectual property. These measures may include confidentiality agreements, secure data storage, and restricted access to sensitive information. By working with reputable foundries and taking appropriate precautions, businesses can minimize the risk of intellectual property theft and ensure that their designs and innovations are protected.

Communication and Language Barriers

Communication and language barriers can be a challenge when sourcing casting services from any foreign country, including China. However, many Chinese foundries have taken steps to improve communication with their international customers and ensure that language barriers do not hinder their ability to deliver high-quality castings.

Many Chinese foundries employ multilingual support teams who are fluent in English and other languages commonly spoken by their customers. These teams are trained to assist with communication, provide technical support, and ensure that customer needs are understood and met. Additionally, many Chinese foundries have implemented digital communication tools, such as video conferencing, email, and instant messaging, to facilitate real-time communication and collaboration with their customers.

By improving communication and addressing language barriers, Chinese foundries have made it easier for international customers to work with them and ensure that their casting needs are met.

In the next section, we will take a closer look at one of the best investment casting factories in China, PrecisionVast Casting, and explore its capabilities and experience.

Best Investment Casting Factory in China

Overview of PrecisionVast Casting’s Experience and Capabilities

PrecisionVast Casting is one of the leading investment casting factories in China, known for its expertise, quality, and customer service. With years of experience in the industry, PrecisionVast has built a strong reputation for delivering high-quality castings that meet the needs of customers around the globe.

PrecisionVast specializes in investment casting, a precision casting process that allows for the production of intricate and complex metal parts. The company is equipped with state-of-the-art equipment and technology, including computer-controlled furnaces, automated molding lines, and advanced inspection systems, which enable it to produce castings with high precision and consistency.

In addition to its advanced equipment, PrecisionVast benefits from a team of experienced engineers and skilled workers who have extensive experience in the field. These professionals undergo continuous training to stay up-to-date with the latest advancements in casting technology and techniques, ensuring that they can deliver castings that meet the highest standards of quality and performance.

Senior Casting Ability

PrecisionVast’s senior casting ability is one of its key strengths. The company has a rich tradition of casting and has developed a deep understanding of the casting process, enabling it to produce high-quality castings with precision and consistency. PrecisionVast’s foundry is equipped with state-of-the-art equipment and technology, allowing it to produce castings with tight tolerances and intricate details, making them suitable for a wide range of applications.

Strict Quality System

Quality is a top priority for PrecisionVast, and the company has implemented a strict quality control system to ensure that its castings meet international standards. PrecisionVast adheres to a range of quality standards, including ISO 9001, ISO 14001, and IATF 16949, and undergoes regular audits to maintain its certifications.

PrecisionVast uses a variety of quality control measures to ensure the consistency and reliability of its castings, including material testing, process control, and inspection and testing. By adhering to strict quality standards and implementing rigorous quality control measures, PrecisionVast has built a reputation for delivering high-quality castings that meet the needs of customers worldwide.

Contact Information and Invitation for Collaboration

If you’re looking for a reliable investment casting partner in China, PrecisionVast Casting is here to help. With its expertise, quality, and commitment to customer service, PrecisionVast is ready to collaborate on your next casting project. Contact PrecisionVast today to learn more about its capabilities and discuss how it can meet your casting needs.

In the next section, we will provide tips on how to choose the right Chinese casting supplier and ensure that your casting needs are met.

How to Choose the Right Chinese Casting Supplier

Research and Due Diligence

Choosing the right casting supplier is critical to the success of your project, and it requires careful research and due diligence. When evaluating potential suppliers, it’s important to consider factors such as their experience, capabilities, quality standards, and customer service.

Start by researching the supplier’s background and reputation. Look for reviews, testimonials, and case studies from previous customers to get a sense of their experience and satisfaction with the supplier. It’s also important to check the supplier’s certifications and ensure that they adhere to international quality standards, such as ISO 9001, ISO 14001, and IATF 16949.

Evaluating Capabilities and Experience

Once you’ve identified potential suppliers, evaluate their capabilities and experience to ensure that they can meet your specific casting needs. Consider factors such as the types of castings they produce, their production capacity, and the materials they work with. It’s also important to assess the supplier’s technical capabilities, including their equipment, technology, and expertise.

Ask the supplier for examples of previous projects they have completed that are similar to your requirements. This will give you a sense of their experience and ability to deliver the castings you need.

Requesting Samples and Prototypes

Before placing a large order, it’s a good idea to request samples or prototypes from the supplier. This will allow you to assess the quality of their castings and ensure that they meet your specifications. It’s also an opportunity to evaluate the supplier’s communication and responsiveness, as well as their ability to meet deadlines and deliver on their promises.

Understanding Terms and Conditions

When working with a new supplier, it’s important to understand the terms and conditions of your agreement. Review the supplier’s contract carefully and ensure that it includes clear terms regarding pricing, delivery, quality standards, and intellectual property protection. It’s also a good idea to discuss any potential issues or concerns with the supplier upfront and ensure that they are addressed in the contract.

By conducting thorough research, evaluating potential suppliers, and understanding the terms and conditions of your agreement, you can ensure that you choose the right Chinese casting supplier for your project.

In the final section, we will explore future trends in the Chinese casting industry and discuss how businesses can stay ahead of the curve.

Future Trends in Chinese Carbon Steel and Investment Casting

Technological Advancements

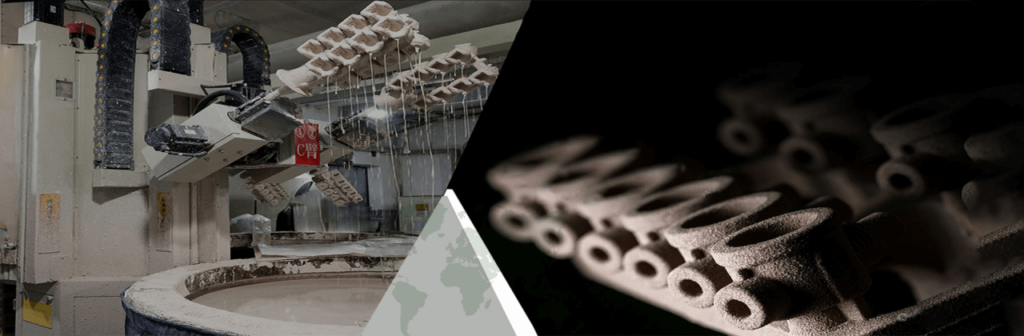

The Chinese casting industry is continuously evolving, with new technological advancements driving innovation and improving the quality and efficiency of casting processes. One of the most significant trends is the adoption of advanced manufacturing technologies, such as 3D printing, automation, and artificial intelligence (AI).

3D printing, also known as additive manufacturing, is revolutionizing the casting industry by allowing foundries to produce complex and intricate parts with greater precision and efficiency. This technology enables rapid prototyping and reduces the need for traditional tooling, resulting in shorter lead times and lower production costs.

Automation is also playing a crucial role in the Chinese casting industry, with many foundries investing in automated molding lines, robotic systems, and computer-controlled furnaces. These technologies help to improve production efficiency, reduce labor costs, and enhance the quality of castings.

Artificial intelligence (AI) is another emerging trend in the casting industry, with many foundries using AI to optimize their production processes, monitor quality, and predict maintenance needs. AI-powered systems can analyze vast amounts of data and identify patterns, enabling foundries to make data-driven decisions and improve their overall performance.

Sustainability Initiatives

Sustainability is becoming increasingly important in the casting industry, and Chinese foundries are taking steps to reduce their environmental impact and adopt more sustainable practices. This includes investing in energy-efficient equipment, reducing waste, and implementing recycling programs.

Many Chinese foundries are also exploring the use of alternative materials, such as bio-based resins and recycled metals, to reduce their carbon footprint and promote sustainability. By adopting green practices and focusing on sustainability, Chinese foundries can meet the growing demand for environmentally friendly castings and contribute to a more sustainable future.

Global Trade Dynamics

Global trade dynamics continue to shape the casting industry, and businesses need to stay informed about the latest developments and trends. Trade policies, tariffs, and geopolitical tensions can have a significant impact on the casting industry, affecting everything from raw material prices to supply chain logistics.

As the global market evolves, businesses need to be agile and adaptable to stay ahead of the curve. This includes diversifying their supply chains, exploring new markets, and investing in new technologies and capabilities. By staying informed and proactive, businesses can navigate the complexities of the global casting industry and ensure their long-term success.

Conclusion

China has established itself as a global leader in the casting industry, offering a combination of high-quality standards, advanced technology, and cost-effective solutions. Whether you’re looking for carbon steel casting or investment casting services, China provides a wide range of options to meet your needs.

By choosing China for your casting needs, you can benefit from the country’s senior casting ability, strict quality system, cost-effectiveness, and logistical advantages. Additionally, by working with reputable Chinese foundries, you can ensure that your casting needs are met with precision, reliability, and quality.

If you’re considering sourcing casting services from China, it’s important to conduct thorough research, evaluate potential suppliers, and understand the terms and conditions of your agreement. By doing so, you can make informed decisions and choose the right casting partner for your project.

In conclusion, China’s casting industry is well-positioned to meet the needs of businesses around the globe, and by staying informed about the latest trends and developments, you can ensure that your casting needs are met now and in the future.